Oil leakage preventing device of upper bent needle of sewing machine

An oil leakage prevention and sewing machine technology, which is applied to sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve the problems of high suction requirements of oil pumps, shortened life of rubber sleeves, affecting oil prevention effect, etc., and achieves good oil prevention effect. Ensure oil absorption capacity and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

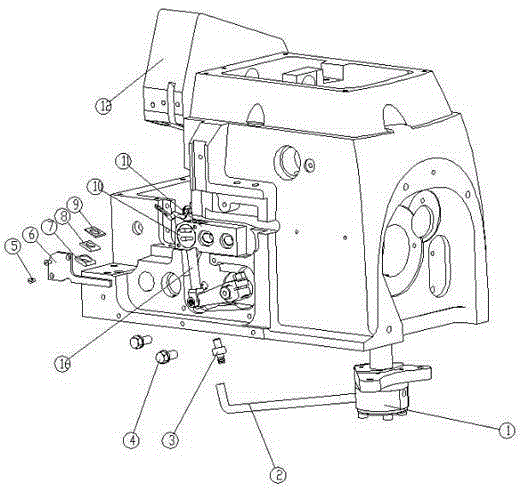

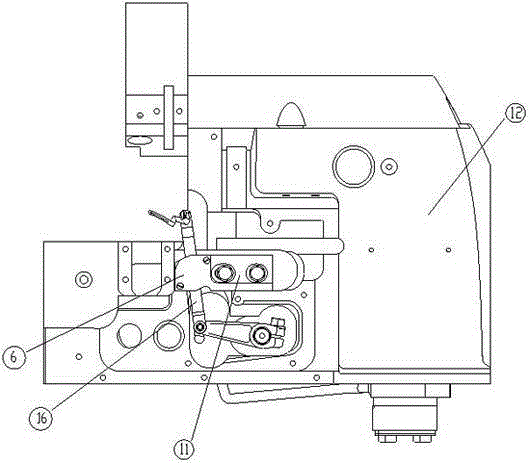

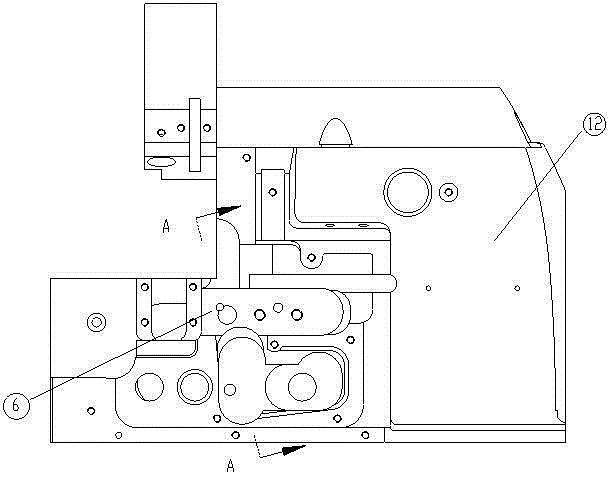

[0020] refer to Figure 1 to Figure 4 The embodiments of the looper oil leakage prevention device on the sewing machine of the present invention will be further described.

[0021] An oil leakage prevention device for an upper looper of a sewing machine, comprising a casing 12, an upper looper sliding rod 16, a looper sliding block 10, and a sliding block seat 11. The upper looper sliding rod 16 and the sliding block seat 11 are assembled on the On the casing 12, the slider seat 11 is assembled on the slider through the slider seat screw 4, the looper slider 10 is assembled in the slider seat 11, and the looper slider 10 is provided with an oil scraping assembly 9 and A number of oil cottons, the oil cotton is located under the oil scraping assembly 9, the oil scraping assembly 9 and the oil cotton are axially movably sleeved on the upper looper sliding rod 16, and the sliding block is provided with a seal outside the oil scraping assembly 9 and the oil cotton. The cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com