Fan transmission device for automobile engine cooling

An automobile engine and fan transmission technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of engine compartment pollution, inability to effectively lubricate grease, and inability to ensure the transmission performance of bearings, so as to ensure cleanliness and avoid dumping. oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

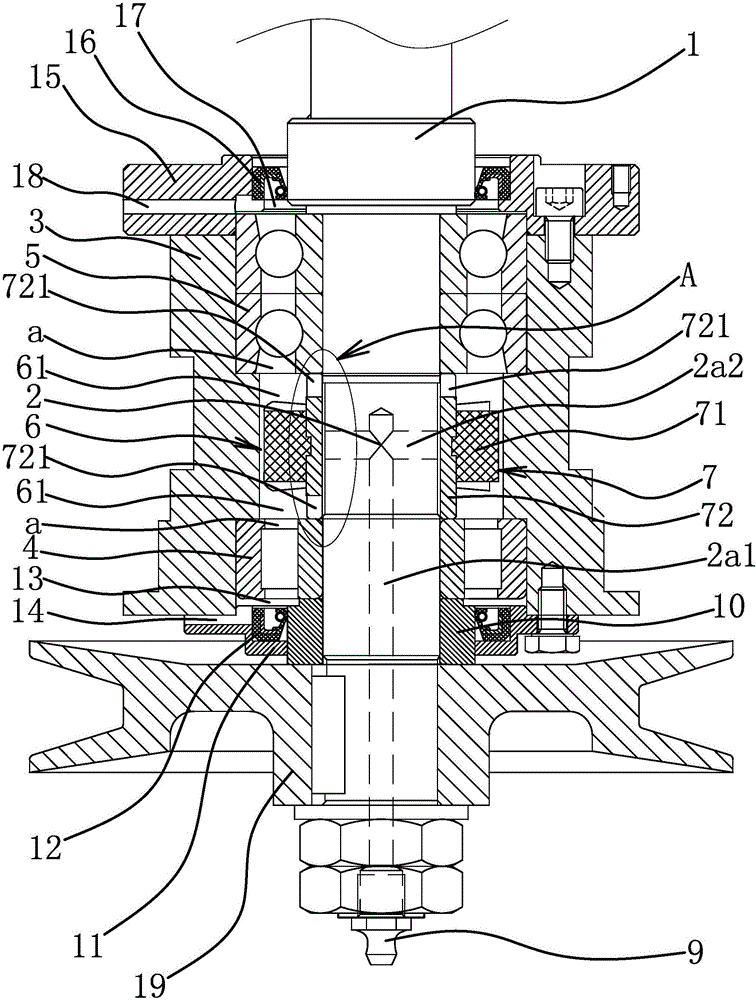

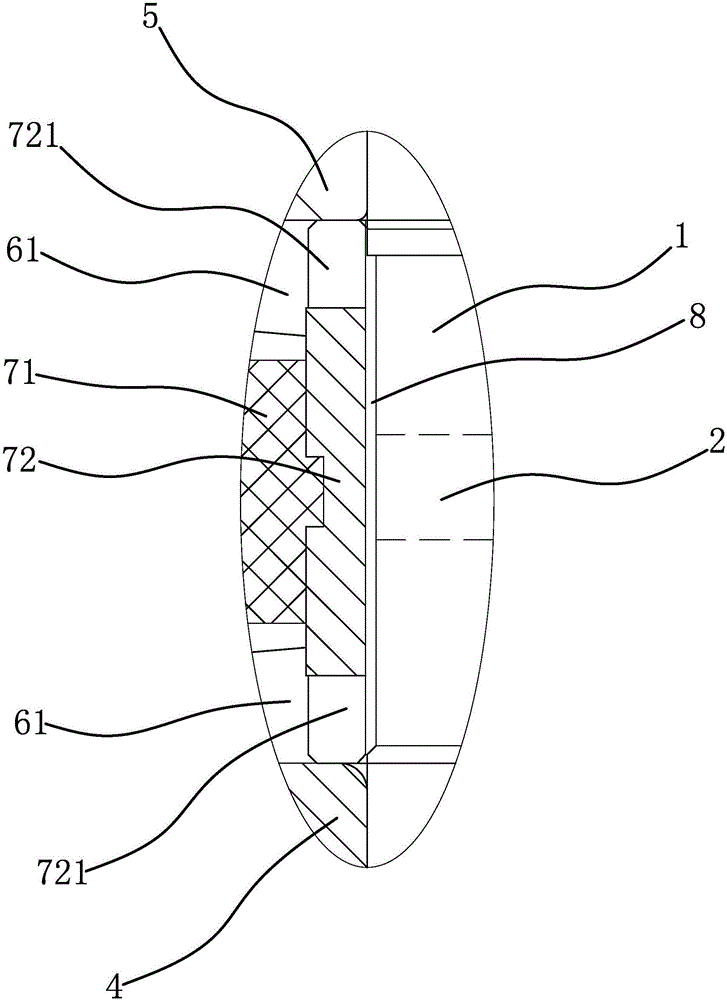

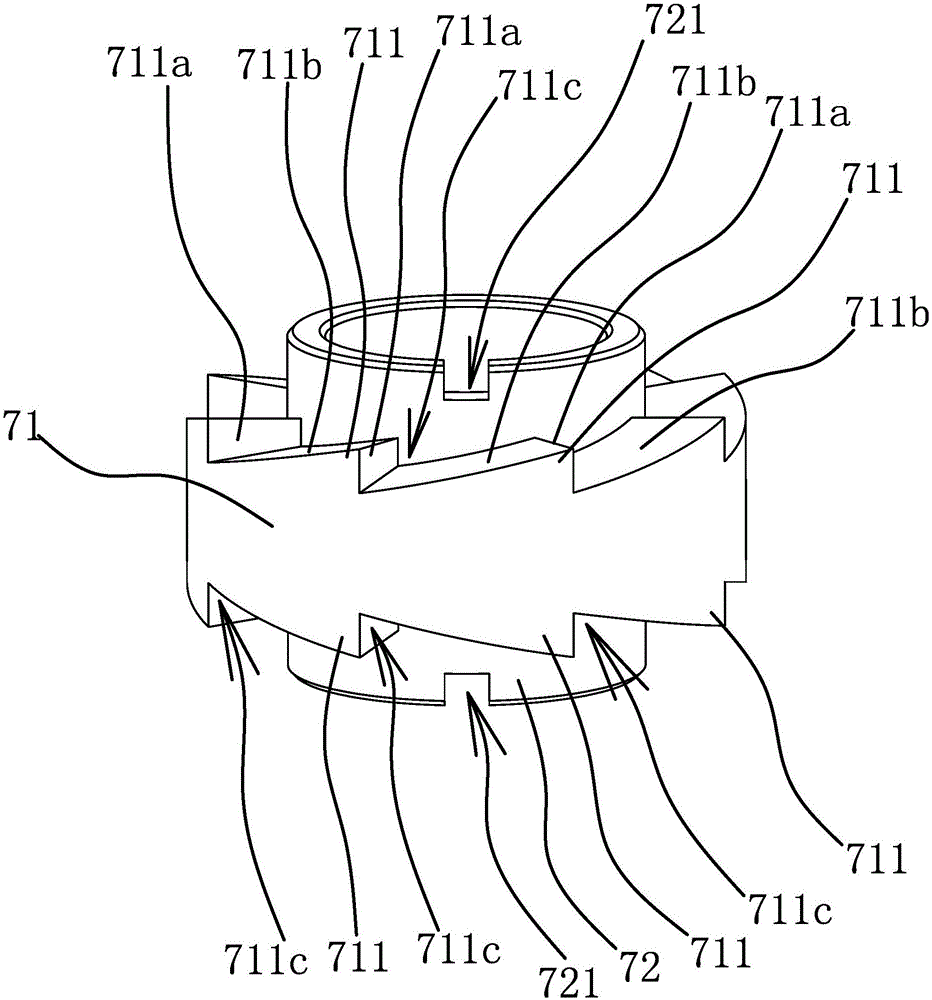

[0027] The fan transmission device for cooling the automobile engine includes a transmission shaft 1, an oil injection passage 2, a main oil passage 2a1, an oil distribution passage 2a2, a support sleeve 3, a bearing 4, a bearing 2 5, a channel a, a working chamber 6, and an oil storage chamber 61. Fan blade spacer 7, fan impeller 71, fan blade teeth 711, oil pushing surface 711a, oil guiding slope 711b, V-shaped port 711c, clamping column 712, sleeve 72, oil outlet groove 721, clamping hole 722, oil passage gap 8. Grease nozzle 9, shaft sleeve 10, oil seal seat 11, oil seal 1 12, seal chamber 1 13, oil drain hole 1 14, connection plate 15, oil seal 2 16, seal chamber 2 17, oil drain hole 2 18, fan drive round 19.

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com