Oil scraping device for silicon steel

An oil scraping device, silicon steel technology, applied in the workpiece cleaning device, workpiece surface treatment equipment, metal rolling and other directions, can solve the problems of affecting the quality of silicon steel products, poor oil scraping effect, frequent replacement, etc., to achieve rubber elasticity, Quick installation and wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

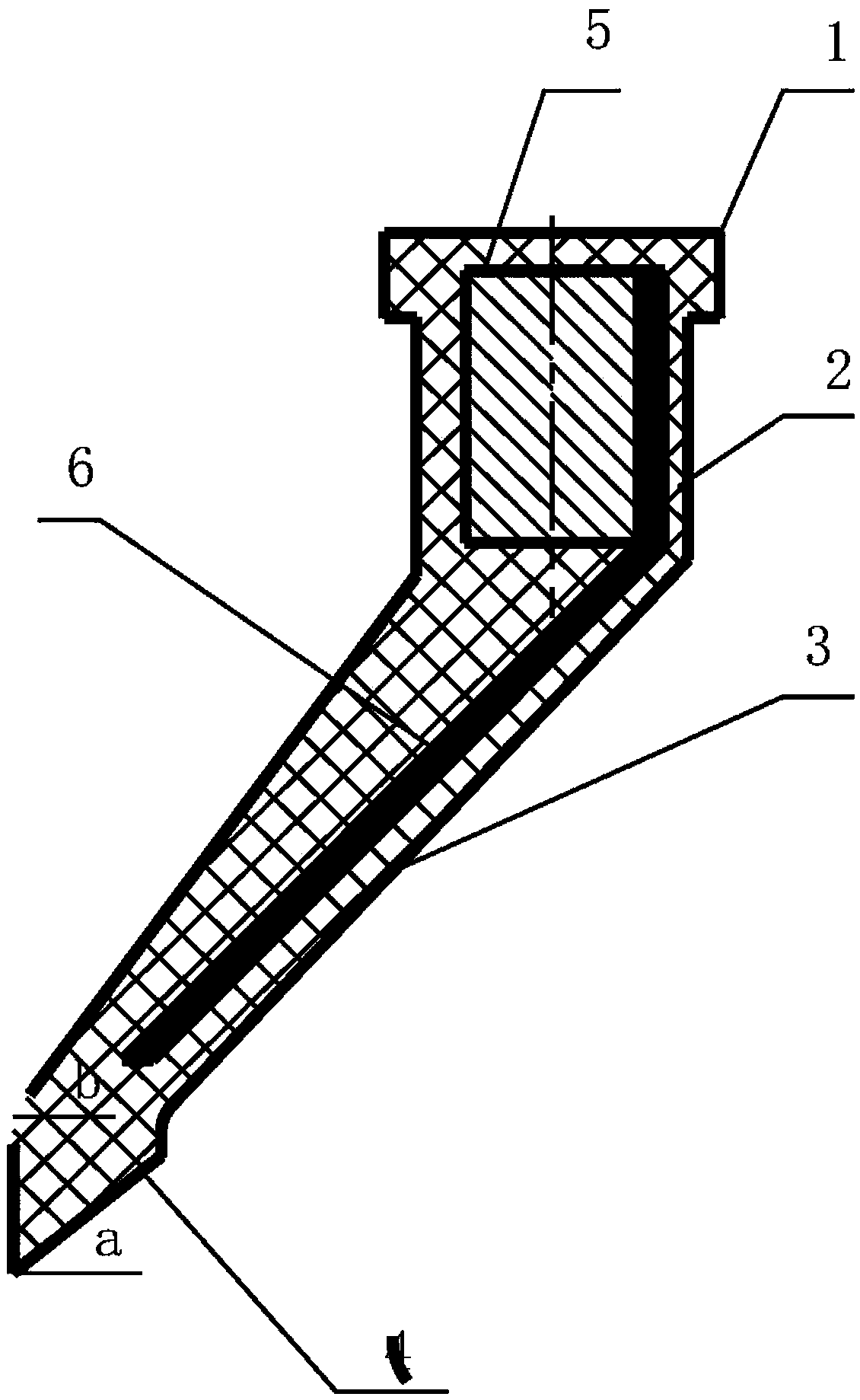

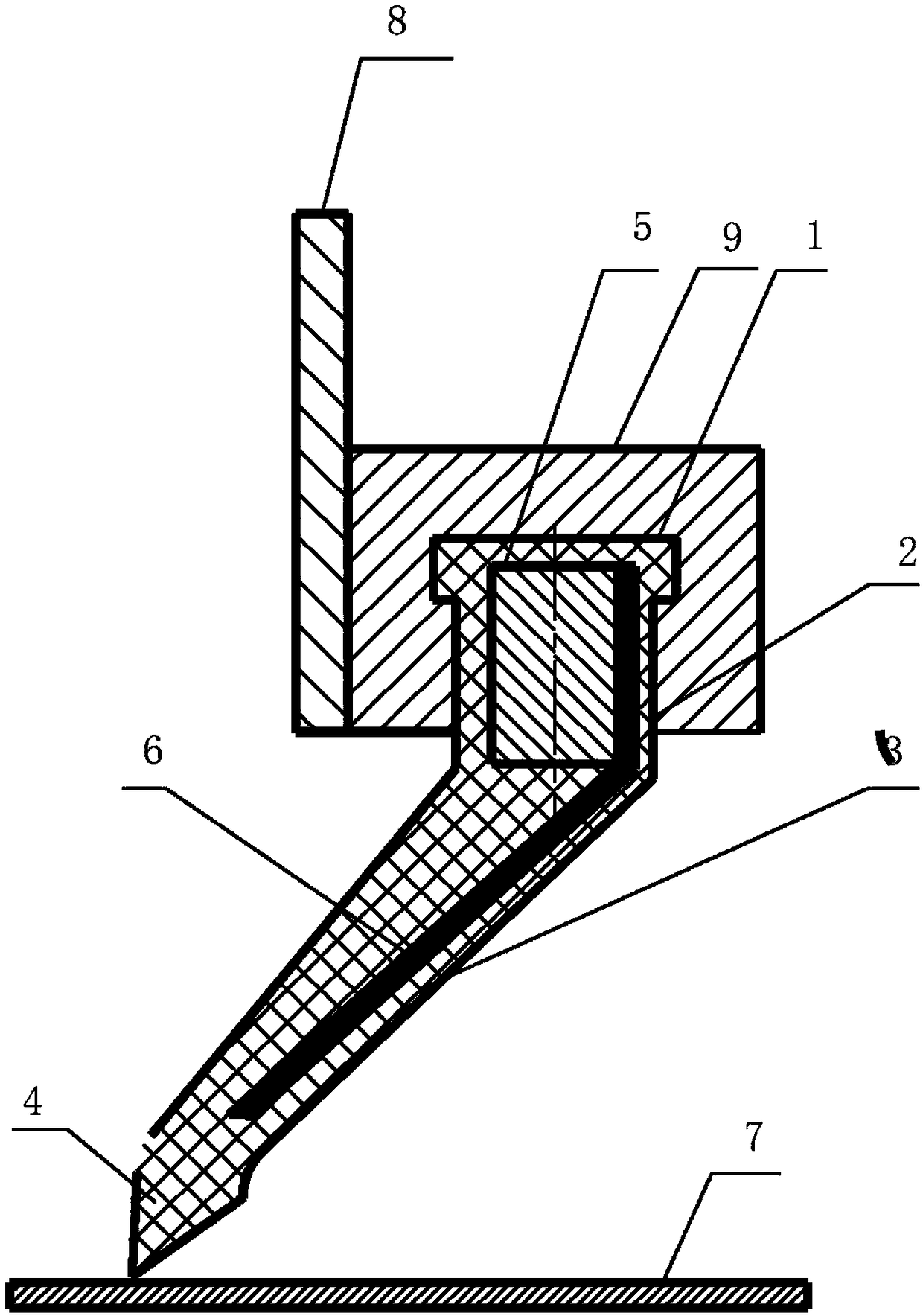

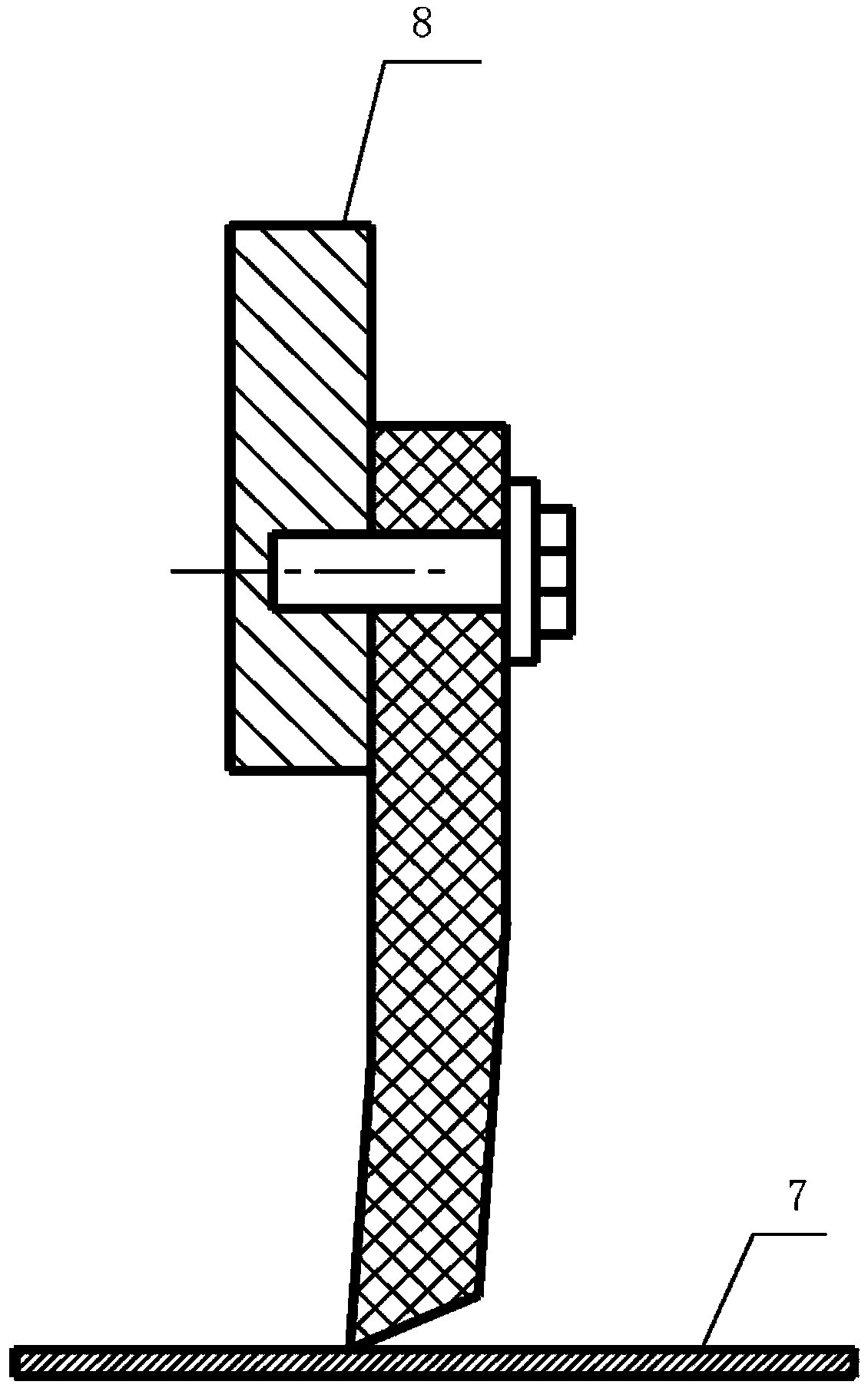

[0025] like figure 1 and figure 2 As shown, the oil scraping device for silicon steel of the present invention includes: an installation slot 9 and an oil scraper, the oil scraper is installed in the slot 9 in a penetrating manner, and the installation slot 9 is fixed on the device 8 by bolts (not shown in the figure) out), the oil scraper includes a boss 1, a vertical section 2, an inclined section 3 and a lip 4 connected in sequence, and the boss 1 and the vertical section 2 are installed in the card slot 9 in a penetrating manner, and the boss 1 is stuck in the installation In the card slot 9. The upper end of the inclined section 3 is connected with the vertical section 2, the lower end of the inclined section 3 is connected with the lip 4, the size from the upper end of the inclined section 3 to the lower end of the inclined section 3 gradually decreases, and the connection between the lip 4 and the inclined section 3 is Smooth arc connection. The cross-sectional sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com