Card leveling mechanism and method of re-transfer card printer

A leveling mechanism and card printer technology, applied in printing devices, printing, etc., can solve the problems of increased printer production costs, reduced printer printing efficiency, and different degrees of card bending, so as to reduce energy consumption and machine material costs, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

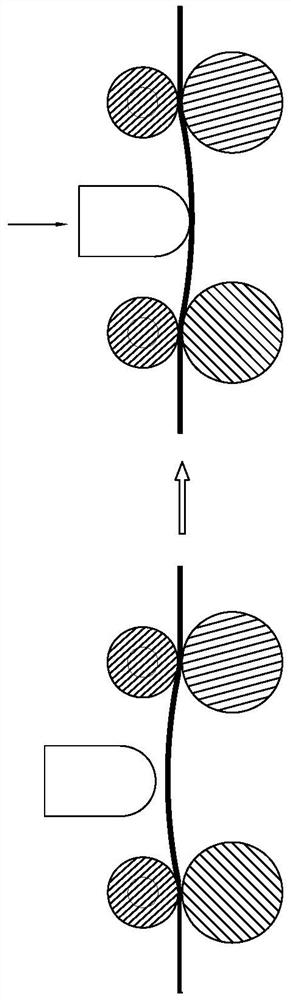

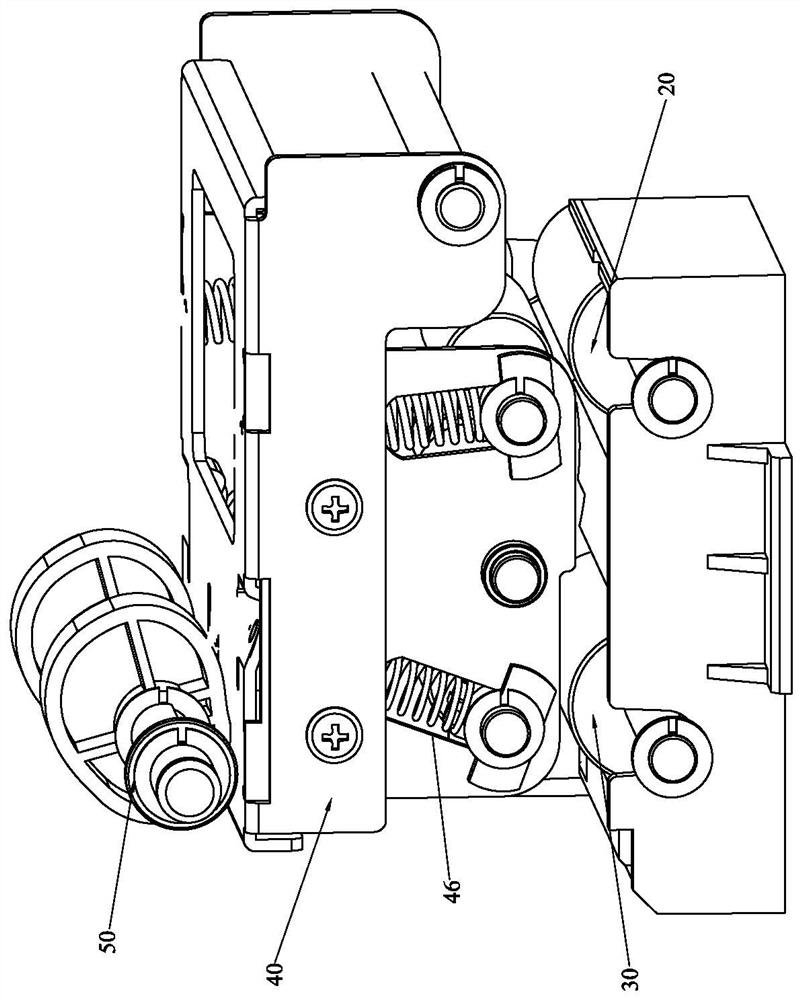

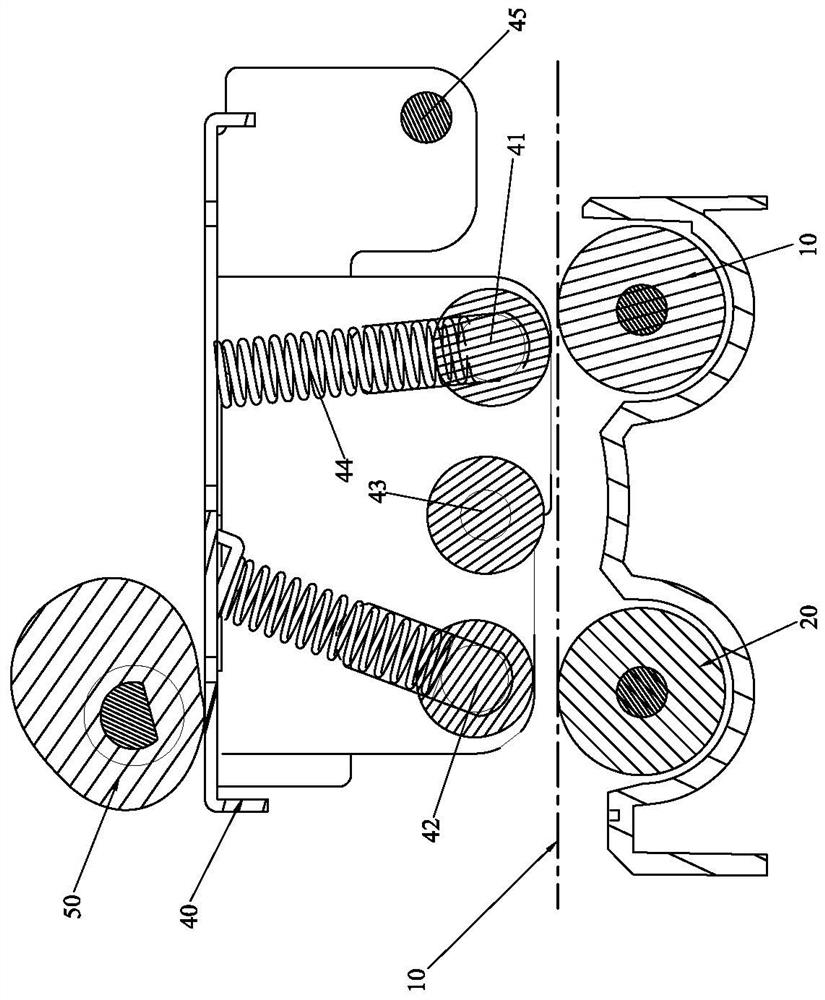

[0049] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the first leveling mechanism driving roller 20 and the second leveling mechanism driving roller located below the transfer plane 10 and arranged at intervals along the card feeding direction 30, also includes a swing leveling assembly, the swing leveling assembly includes a leveling mechanism support 40 and a first leveling mechanism idler 41 mounted on the leveling mechanism support 40 and located above the transfer plane 10, a second leveling mechanism Two leveling mechanism idlers 42, leveling rollers 43, the first leveling mechanism idlers 41, leveling rollers 43, and the second leveling mechanism idlers 42 are arranged at successive intervals along the card feeding direction, and the first leveling The leveling mechanism idler 41 and the second leveling mechanism idler 42 are all provided with a leveling spring 44 to provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com