A kind of weathering steel hot-rolled thin strip without p segregation and its manufacturing method

A manufacturing method and technology of weathering steel, which is applied in the field of alloy steel manufacturing, can solve the problems of difficult control of plate shape, unfavorable transverse toughness and anisotropy of steel, etc., achieve fewer production processes, reduce production costs and labor components, and improve the surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

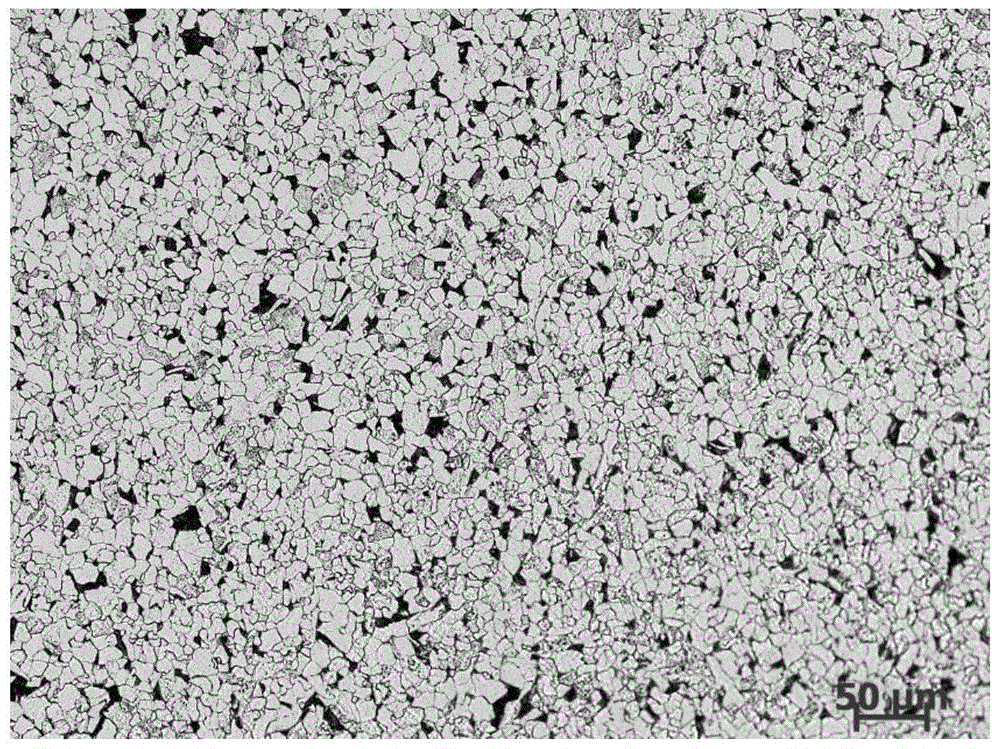

Embodiment 1

[0060] (1) Smelting: Pre-desulfurization of molten iron, compound blowing of converter top and bottom, RH vacuum cycle deoxidation process, calcium treatment and LF refining at the same time, to obtain molten steel with qualified components, by weight percentage: C: 0.08%, Si: 0.30% , Mn: 0.48%, P: 0.08%, S: 0.005%, Cr: 0.60%, Ni: 0.04%, Cu: 0.27%, Al: 0.03%, B: 0.003%, and the balance is iron and impurity elements.

[0061] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by twin-roll thin strip casting and rolling equipment. With continuous casting. A cast strip with a thickness of 3 mm is obtained.

[0062] (3) Hot rolling: the cast strip is then rolled into a thin strip of 2.6mm through one pass of hot rolling with a reduction of 13%, and the hot rolling temperature is 1050°C.

[0063] (4) Cooling and coiling: the hot-rolled thin strip is cooled to 600°C at a rate of 45°C / s, and the hot-rolled coil is obtained after coilin...

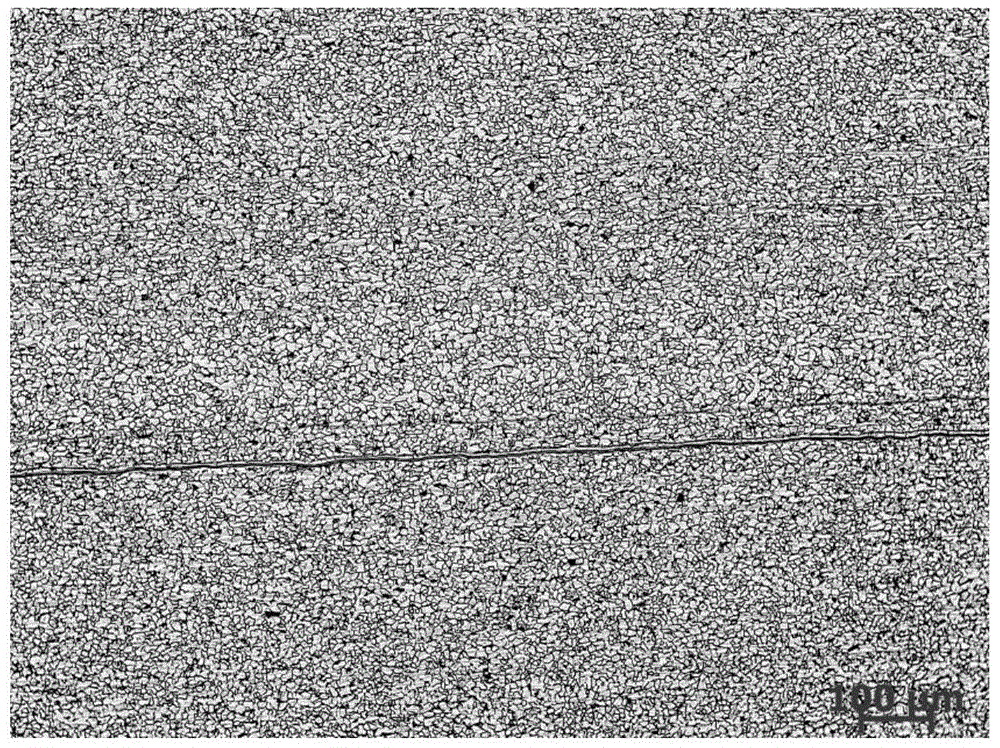

Embodiment 2

[0068] (1) Smelting: Pre-desulfurization of molten iron, top-bottom compound blowing of converter, RH vacuum cycle deoxidation process, calcium treatment and LF refining at the same time, to obtain molten steel with qualified components, by weight percentage: C: 0.07%, Si: 0.33% , Mn: 0.46%, P: 0.09%, S: 0.008%, Cr: 0.80%, Ni: 0.08%, Cu: 0.3%, Al: 0.04%, B: 0.001%, and the balance is iron and impurity elements.

[0069] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by twin-roll thin strip casting and rolling equipment. With continuous casting. A cast strip having a thickness of 2.0 mm was obtained.

[0070] (3) Hot rolling: the cast strip is then rolled into a thin strip of 1.6mm through one pass of hot rolling with a reduction of 19.9%, and the hot rolling temperature is 950°C.

[0071] (4) Cooling and coiling: the hot-rolled thin strip is cooled to 520°C at a rate of 30°C / s, and the hot-rolled coil is obtained after coili...

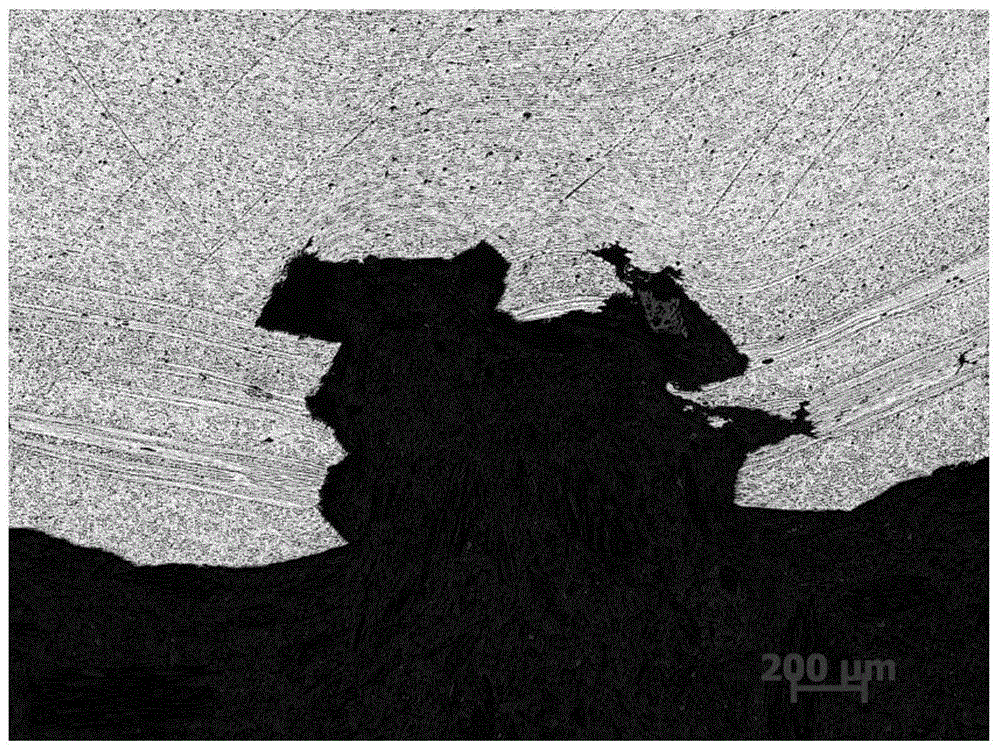

Embodiment 3

[0075] (1) Smelting: Pre-desulfurization of molten iron, compound blowing at the top and bottom of converter, RH vacuum cycle deoxidation process, calcium treatment and LF refining at the same time, to obtain molten steel with qualified components, by weight percentage: C: 0.11%, Si: 0.46% , Mn: 0.50%, P: 0.13%, S: 0.005%, Cr: 0.70%, Ni: 0.11%, Cu: 0.4%, Al: 0.03%, B: 0.002%, and the balance is iron and impurity elements.

[0076] (2) Thin strip continuous casting: The molten steel with qualified composition is cast and rolled by twin-roll thin strip casting and rolling equipment. With continuous casting. A cast strip with a thickness of 1.2 mm was obtained.

[0077] (3) Hot rolling: the cast strip is then rolled into a thin strip of 1.14mm by one pass of hot rolling with a reduction of 5%, and the hot rolling temperature is 860°C.

[0078] (4) Cooling and coiling: the hot-rolled thin strip is cooled to 550°C at a rate of 20°C / s, and the hot-rolled coil is obtained after coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com