Wiper arrangement and compressor with such a wiper arrangement

A technology of oil scraping device and compressor, which is applied in the direction of mechanical equipment, engine components, engine sealing, etc., to achieve the effects of reducing wear, improving oil scraping effect, and good oil scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

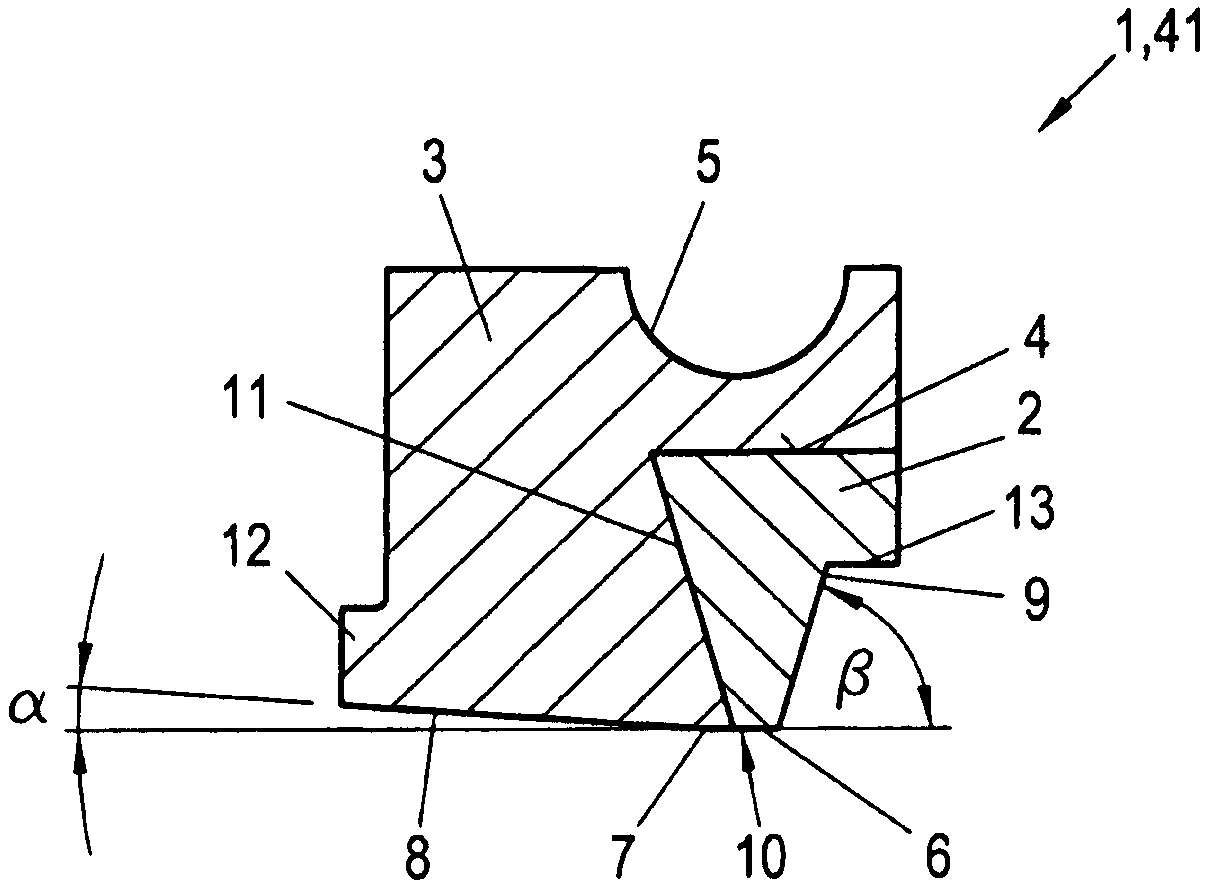

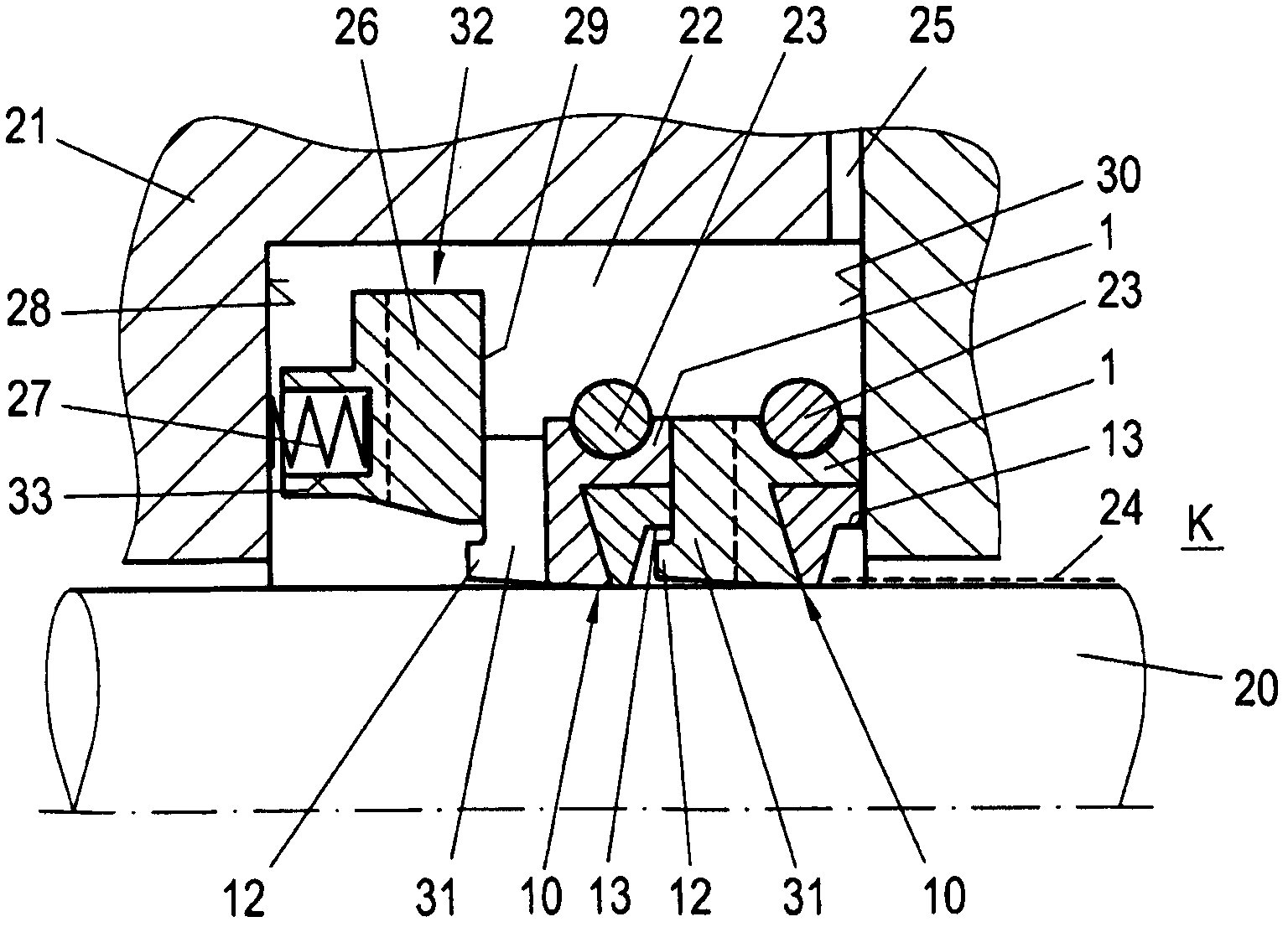

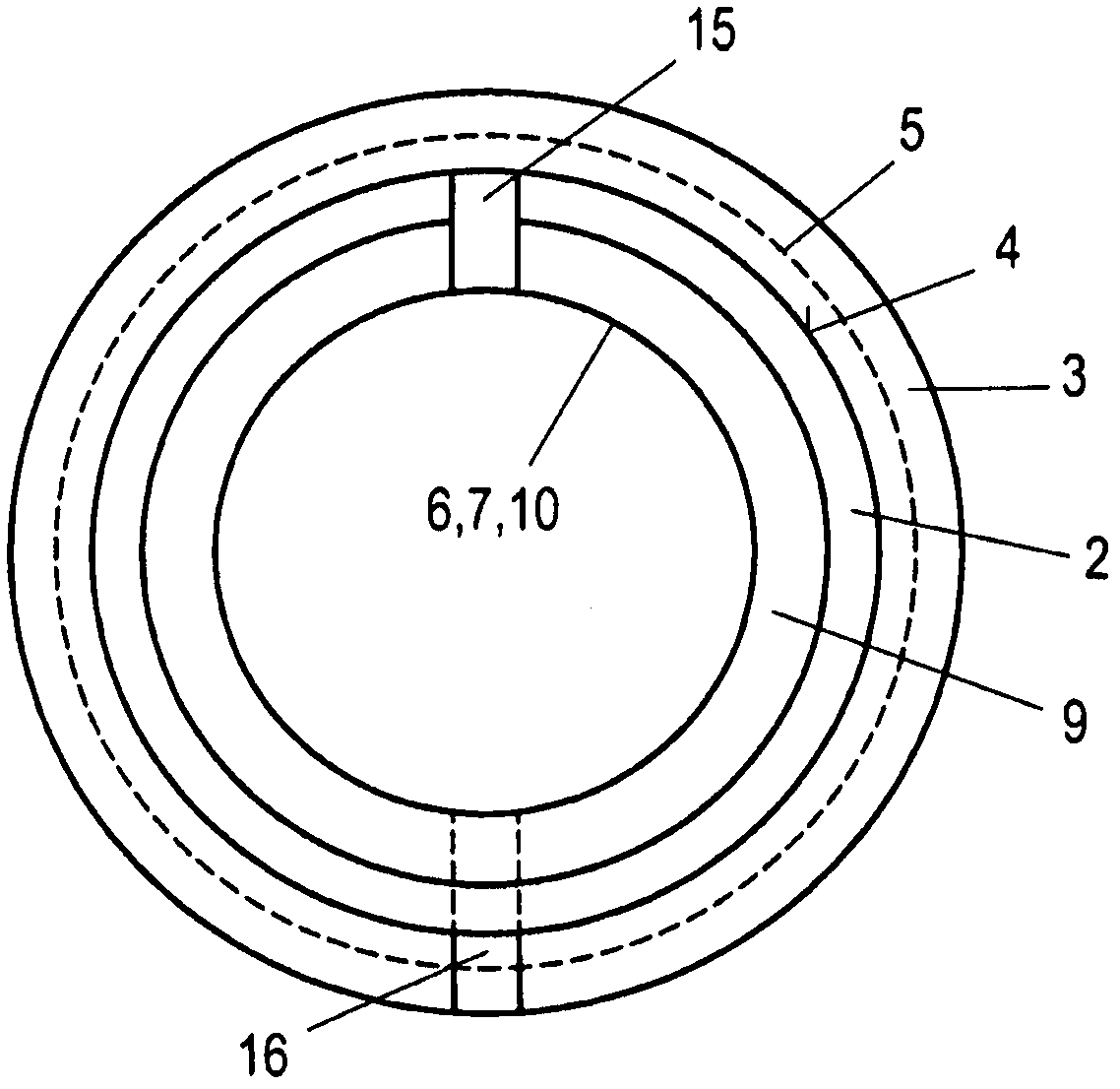

[0029] An advantageous embodiment of the oil scraping device 1 according to the invention is shown in figure 1 , 2 and 6 in. The oil scraper device 1 comprises a circumferentially divided oil scraper ring 2 and a circumferentially divided L-shaped locking ring 3 . The wiper ring 2 and the locking ring 3 are advantageously split radially at one or more points and are preferably made of one plastic, possibly also of different materials or plastics. In this case, the radial gap 15 in the circumferential direction in the wiper ring 2 and the radial gap 16 in the circumferential direction in the locking ring 3, as shown in figure 2 As shown in , they are staggered from each other along the circumferential direction (here staggered by 180°). However, the separation in the circumferential direction can be configured differently in any desired manner, for example in a tangential or locking manner. In the locking ring 3, a recess 5 for receiving a circumferential spring is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com