Secondary envelope surface type rotary air compressor

A secondary envelope, gas compressor technology, applied in the direction of rotary piston pumps, rotary piston machines, liquid fuel engines, etc., can solve the problems of stator line wear, leakage increase, compressor failure, etc., to achieve extended use Longer life, improved anti-friction and anti-wear capabilities, and improved friction and wear conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

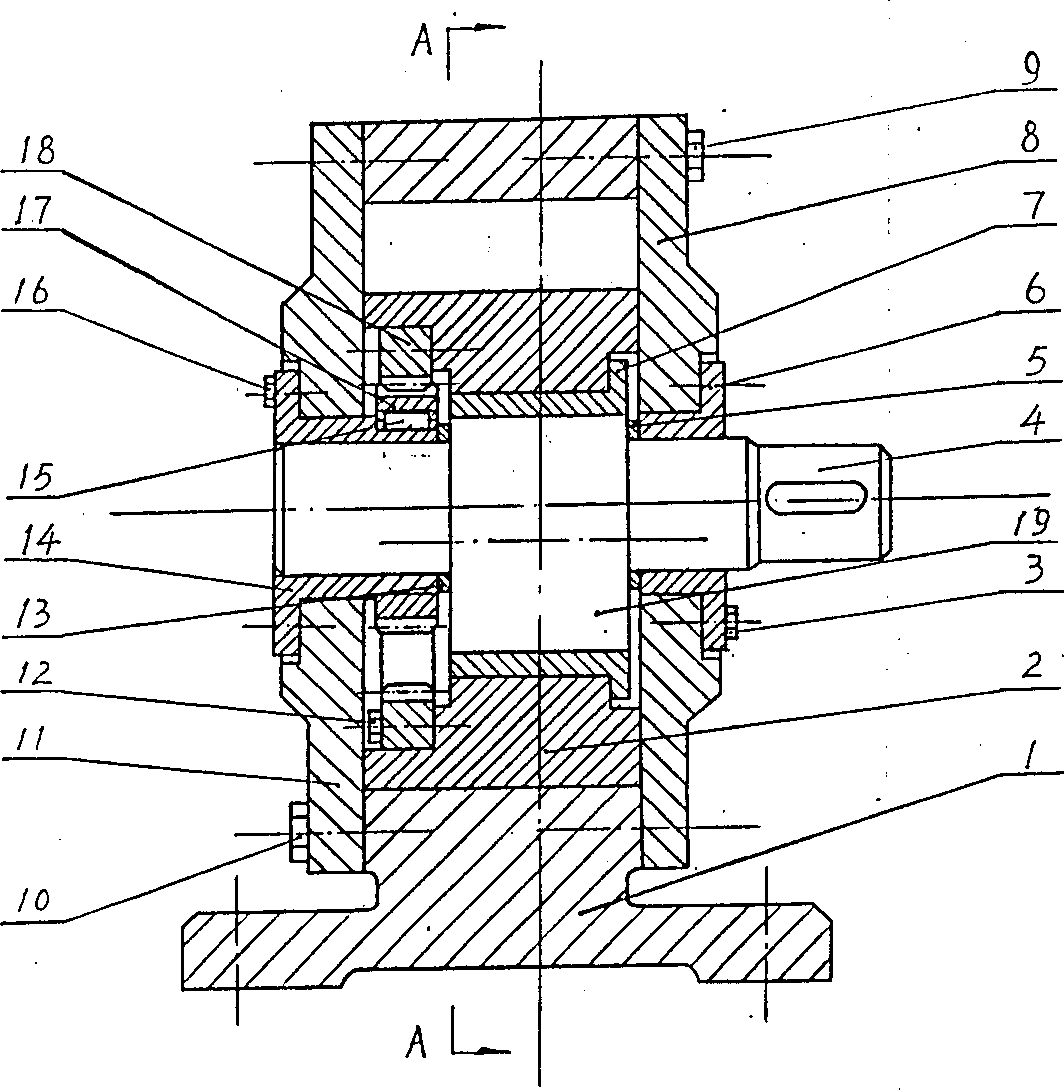

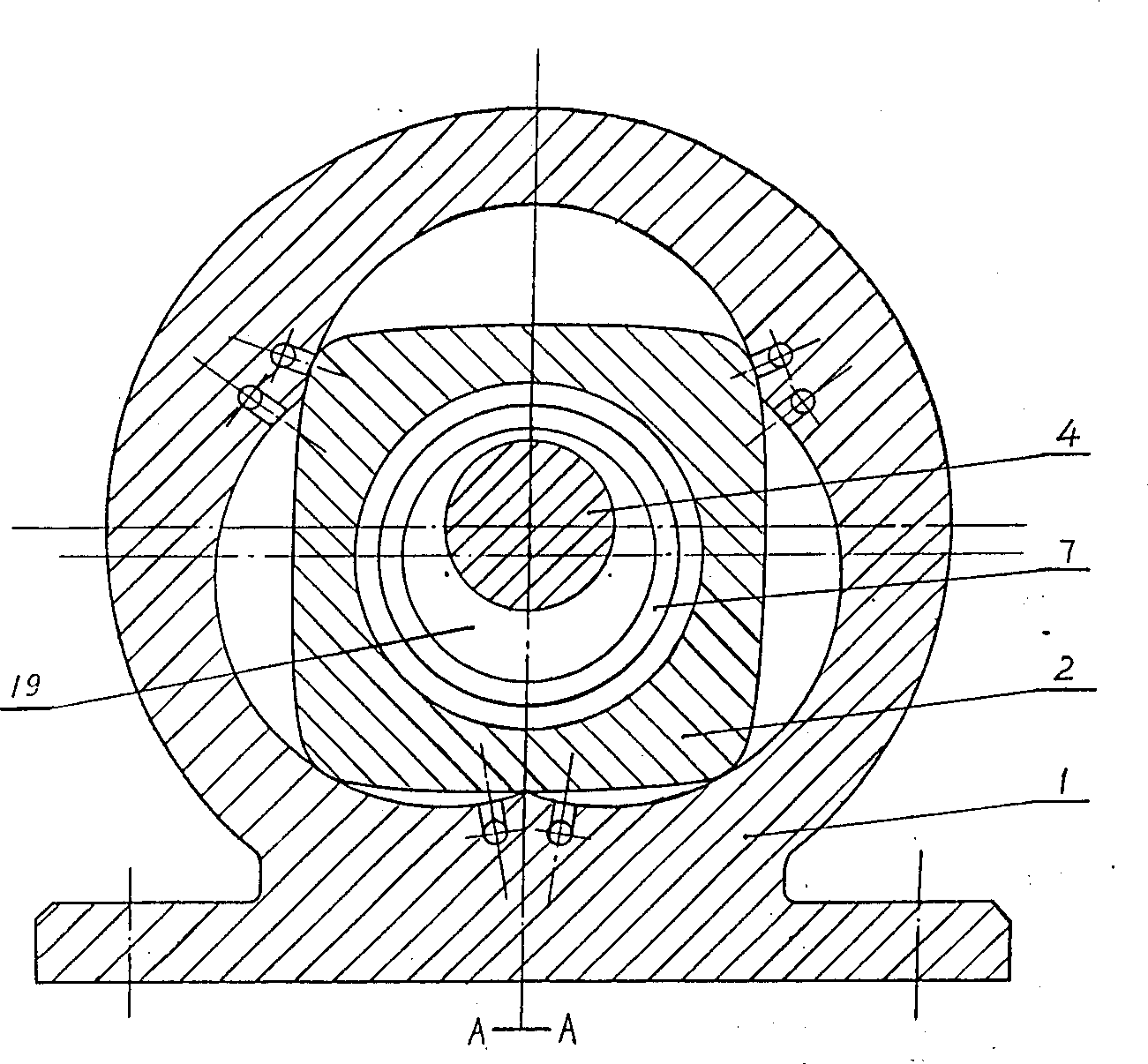

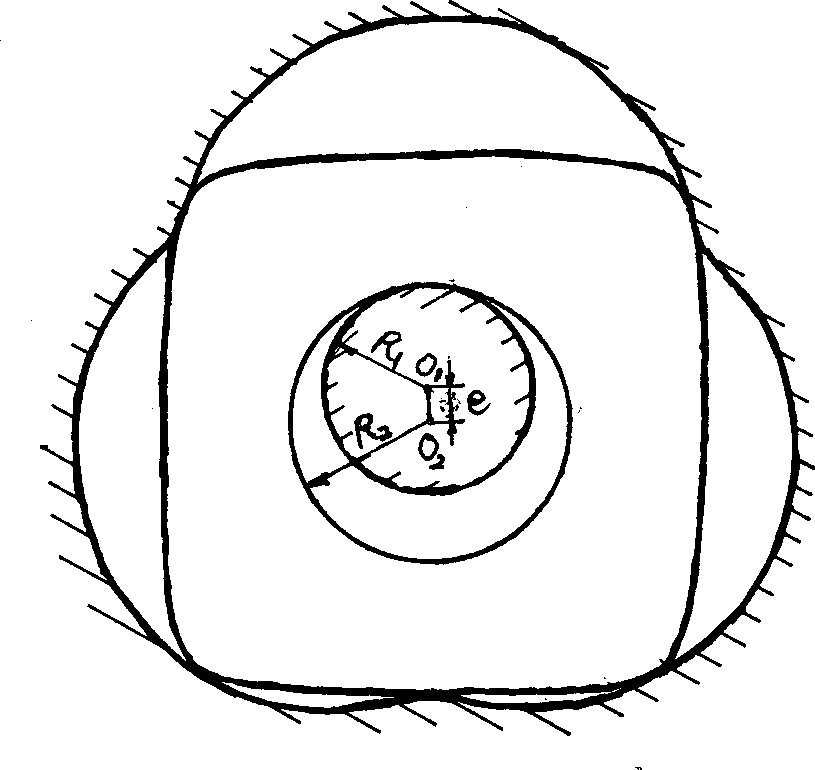

[0015] When the speed ratio is 3:4, the creation radius = 48mm, and the eccentricity = 12mm, the four top corners of the rotor are respectively processed into the same arc-shaped grooves, and the centers of the arcs are respectively at the theoretical profile of the rotor. Four vertices, each arc groove has an oil hole to communicate with the rotor bearing lubrication system, as attached Figure 4 shown. A cylinder is installed in each arc-shaped groove to roll and fit with it. The radius of the cylinder is equal to the translation distance of the stator profile from the theoretical profile to the actual profile. The translation distance takes into account the size, lubrication and accumulation of the stator and rotor. The length of the cylinder is the thickness of the rotor, the gap between the arc groove and the cylinder is 0.05-0.8mm, and the intersection of the arc groove at the top corner of the rotor and the rotor profile line and the adjacent The rotor profile is modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com