Composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing same

A technology of extreme pressure anti-wear agent and anti-wear hydraulic oil, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of limiting the application range of non-petroleum hydraulic oil, and achieve the maximum non-jamming load and anti-wear The effect of performance improvement, wear reduction, and good extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

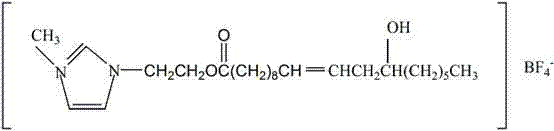

[0048] Structural formula ( ) represents the preparation of A ionic liquid:

[0049] A) Pump the metered ricinoleic acid and 1-(2-hydroxy)ethyl-3 methylimidazolium tetrafluorophosphate (pumping molar ratio 1.05 to 1) into the reaction kettle, add anhydrous DMF (dimethyl base formamide) as the reaction medium (the volume of ricinoleic acid is 3 to 1), stirring and mixing evenly;

[0050] B) Pump in the catalyst alkyl pyridyl tetrafluoroborate (the molar ratio of ricinoleic acid to ricinoleic acid is 1 to 20), stir and mix evenly, and heat with heat transfer oil, the reaction temperature is controlled at 120°C, and water is removed with a water separator 6 hours of reaction;

[0051]C) After the reaction, the reaction solvent DMF was distilled off under reduced pressure to obtain 1-(ethyl ricinoleate)-3-methylimidazolium tetrafluoroborate ionic liquid.

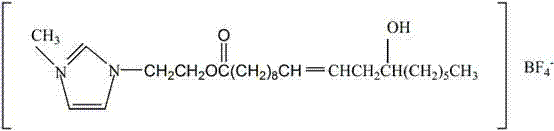

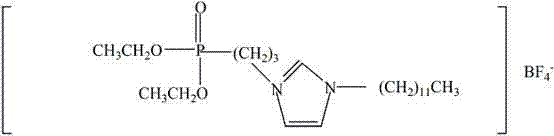

[0052] Structural formula ( ) represents the preparation of the B ionic liquid:

[0053] A) Pump dodecyl imidazole and ...

Embodiment 2

[0060] Fully synthetic anti-wear hydraulic oil formula:

[0061] Water base oil 60.3Kg

[0062] Viscosity modifier (ethylene oxide-propylene oxide copolymer) 19.5 Kg

[0063] PH value adjuster (triethanolamine) 5Kg

[0064] Composite extreme pressure antiwear agent 9.6Kg

[0065] Friction reducer 3.5 Kg

[0066] Rust inhibitor 2Kg

[0067] Fungicide 0.1 Kg

[0068] Water-based silicon-containing defoamer 0.05 Kg

[0069] The water-based base oil is an aqueous solution of dimethyl sulfoxide, and the mass percentage of dimethyl sulfoxide is 40%;

[0070] The composite extreme pressure antiwear agent is prepared by the method described in Example 1;

[0071] Described antifriction agent is the mixture of ricinoleic acid soap and tributyl phosphate, and the mass ratio of ricinoleic acid soap and tributyl phosphate is 19:1;

[0072] The antirust agent is a mixture of boric acid and benzotriazole, and the mass ratio of boric acid and benzotriazole is 9:1;

[0073] The fungi...

Embodiment 3

[0080] Fully synthetic anti-wear hydraulic oil formula:

[0081] Water base oil 60.9Kg

[0082] Viscosity modifier (polyethyleneimine) 20Kg

[0083] PH value regulator (triethanolamine) 5.5Kg

[0084] Composite extreme pressure antiwear agent 8Kg

[0085] Friction reducer 3.5 Kg

[0086] Rust inhibitor 2 Kg

[0087] Bactericide (dodecyldimethylbenzyl ammonium chloride) 0.1 Kg

[0088] Polyether polyol defoamer 0.005 Kg

[0089] The water-based base oil is an aqueous solution of dimethyl sulfoxide, and the mass percentage of dimethyl sulfoxide is 40%;

[0090] The composite extreme pressure antiwear agent is prepared by the method described in Example 1;

[0091] The friction reducer is a mixture of sodium ricinoleate and potassium dimer acid, and the mass ratio of sodium ricinoleate to potassium dimer acid is 9:1;

[0092] The antirust agent is a mixture of boric acid and octanoic acid, and the mass ratio of boric acid to octanoic acid is 9:1.

[0093] The preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com