Bimetal composite hammer manufacture method and hammer handler precasting products

A composite hammer head and bimetal technology, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of easy falling off and lower performance, and achieve high bonding strength, low production cost, and improved impact toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

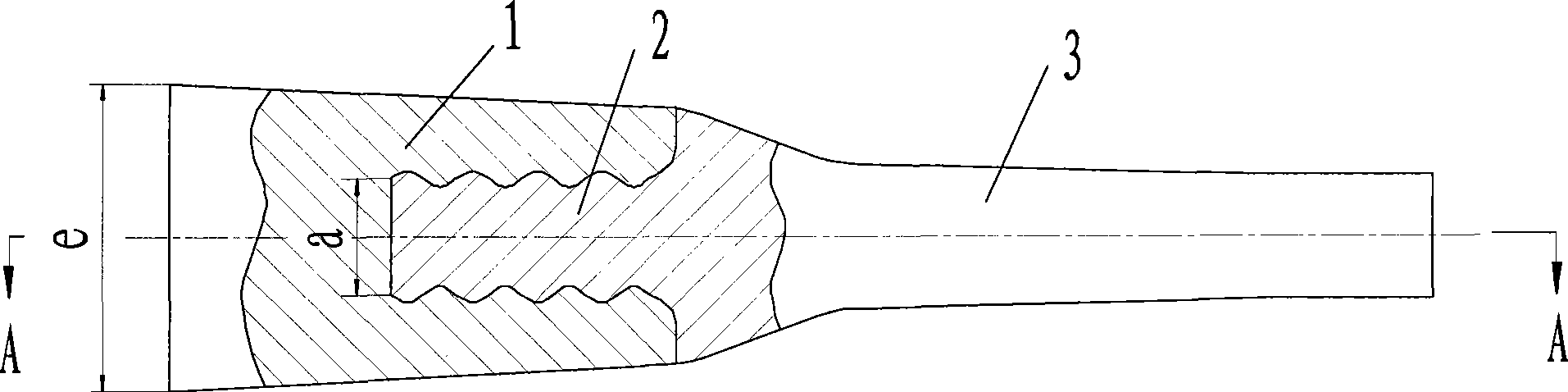

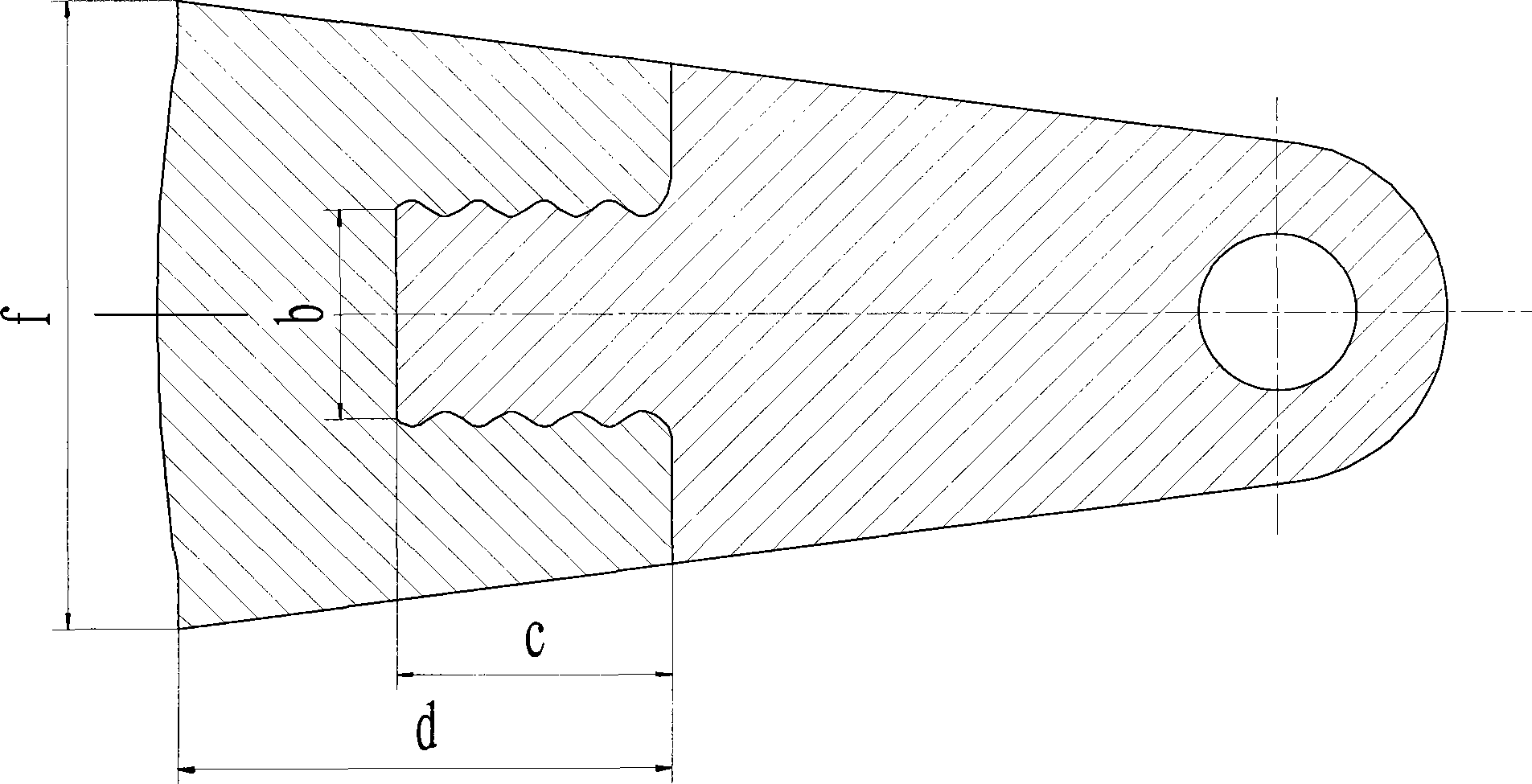

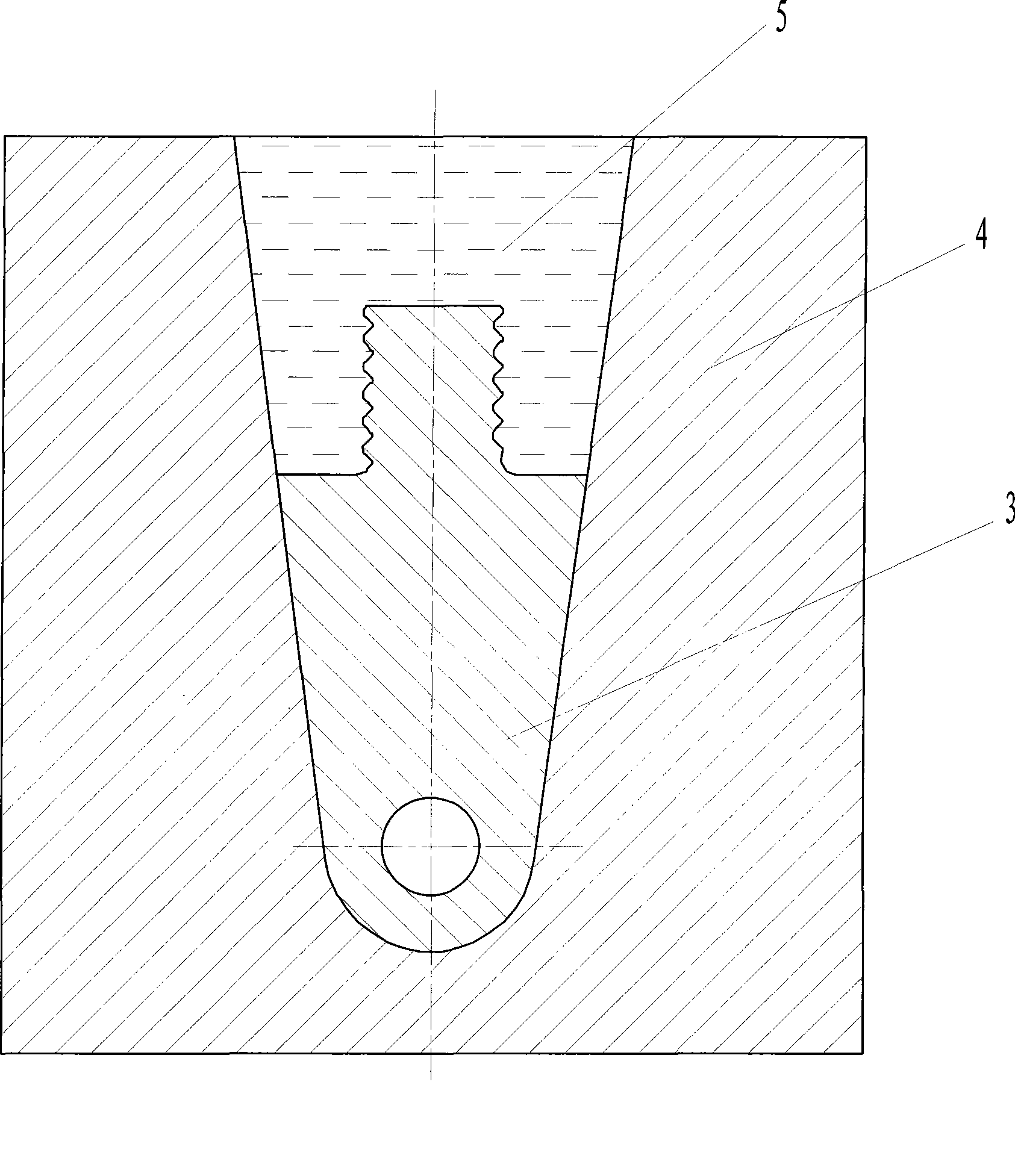

[0034] A high chromium cast iron / high manganese steel bimetal composite hammerhead for a hammer crusher with a single piece weight of 55 kg was prepared. The length d of the hammerhead head 1 is 170 mm, the width f is 190 mm, and the thickness e is 110 mm.

[0035] Hammer handle preform 3 is made of high manganese steel with brand ZGMn13, and its impact toughness at room temperature is 15J / cm 2 And the hardness is 25HRC, and it is formed by sand casting method. The length c of the connecting handle 2 of the hammer handle preform is 136 mm, the width b is 95 mm, and the thickness a is 55 mm. There is an annular groove with a depth of 5mm and a width of 10mm on the surface of the connecting handle of the prefabricated hammer handle.

[0036] A kind of concrete steps of the preparation method of bimetal composite hammer head are as follows:

[0037] Step 1: Coat the surface of the prefabricated part of the hammer handle with a borate heat treatment protective coating, and heat...

Embodiment 2

[0044] Prepare a low-chromium cast iron / ZG35 steel bimetal composite hammer head for a hammer crusher with a single piece weight of 5 kg. The length d of the hammerhead head 1 is 60 mm, the width f is 100 mm, and the thickness e is 50 mm.

[0045] Hammer handle prefabrication 3 is made of cast steel with grade ZG35, and its impact toughness at room temperature is 5J / cm 2 And the hardness is 35HRC, and it is formed by sand casting method. The length c of the connecting handle 2 of the hammer handle preform is 35 mm, the width b is 40 mm, and the thickness a is 22 mm. There is an annular groove with a depth of 3 mm and a width of 5 mm on the surface of the connecting handle of the prefabricated hammer handle.

[0046] A kind of concrete steps of the preparation method of bimetal composite hammer head are as follows:

[0047] Step 1: Coat the surface of the prefabricated part with a silicate heat treatment protective coating, and heat it to 400°C for 30 minutes.

[0048] Step...

Embodiment 3

[0054] A medium manganese steel / 40Cr steel bimetallic composite hammer head for a hammer crusher with a single piece weight of 5 kg was prepared. The length d of the hammerhead head 1 is 60 mm, the width f is 100 mm, and the thickness e is 50 mm.

[0055] Hammer handle preform 3 is made of 40Cr forged steel and machined into shape; its room temperature impact toughness is 20J / cm 2 And the hardness is 40HRC. The length c of the connecting handle 2 of the hammer handle preform is 15 mm, the width b is 33 mm, and the thickness a is 16.6 mm. There is an annular groove with a depth of 2mm and a width of 3mm on the surface of the connecting handle of the prefabricated hammer handle.

[0056] A kind of concrete steps of the preparation method of bimetal composite hammer head are as follows:

[0057] Step 1: Coat the surface of the prefabricated part with an alcohol boric acid heat treatment protective coating, and heat it to 300°C for 20 minutes.

[0058] Step 2, apply forsterite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com