Preparation method of fibrous nano silicon carbide

A nano-silicon carbide and fibrous technology, applied in the field of compound preparation, can solve the problems of environmental pollution, low yield, high cost, etc., and achieve the effect of simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

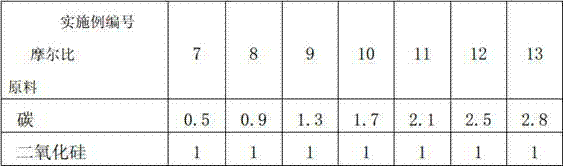

Examples

Embodiment 1

[0026] Fiber serpentine (SiO 2 ), the carbon airgel was dried in a vacuum drying oven (300-1000Pa, 50-80°C, 3-12h), and an appropriate amount of fiber serpentine (SiO 2 ), carbon aerogels, grind them separately, pass through a 200-mesh sieve, take samples at a molar ratio of 2:1, and mix them evenly; the mixed mixture should have a bulk density of 0.3-1.5 g / cm 3 Put it into the alumina crucible of the tubular atmosphere furnace, evacuate it to 0.001MPa, and continuously feed high-purity argon gas (purity 99.99%, protective atmosphere) into the reaction device, then raise the temperature to 1350 ° C, the sample reacts, and keep warm for 0.2 After ~6h, cool down to room temperature, stop feeding the protective atmosphere, collect the combustion products, and obtain fibrous nano-silicon carbide powder after fine grinding.

Embodiment 2

[0028] Fiber serpentine (SiO 2 ) and graphene in a vacuum drying oven (300-1000Pa, 50-80°C, 3-12h), take an appropriate amount of fiber serpentine (SiO 2 ), graphene, grind them separately, pass through a 200-mesh sieve, take samples at a molar ratio of 2:1, and mix them evenly; the mixed mixture should have a bulk density of 0.3-1.5 g / cm 3 Put it into the alumina crucible of the tubular atmosphere furnace, evacuate it to 0.001MPa, and continuously feed high-purity argon gas (purity 99.99%, protective atmosphere) into the reaction device, then raise the temperature to 1400 ° C, the sample reacts, and keep warm for 0.2 After ~6h, cool down to room temperature, stop feeding the protective atmosphere, collect the combustion products, and obtain fibrous nano-silicon carbide powder after fine grinding.

Embodiment 3

[0030] Fiber serpentine (SiO 2 ), carbon black in a vacuum drying oven (300-1000Pa, 50-80°C, 3-12h), then take an appropriate amount of fiber serpentine (SiO 2 ), carbon black, grind them separately, pass through a 200-mesh sieve, take samples at a molar ratio of 1:1, and mix them evenly; the mixed mixture should have a bulk density of 0.3-1.5 g / cm 3 Put it on the refractory material of the high-temperature self-propagating reaction technology preparation device, evacuate to 0.001MPa, and continuously feed high-purity argon gas (purity 99.99%, protective atmosphere) into the reaction device, and then raise the temperature to 1450 ° C to achieve the sample. Ignition, sample reaction; keep warm for 0.2~6h, cool to room temperature, stop the protective atmosphere, collect the combustion products, after fine grinding, the fibrous nano-silicon carbide powder can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com