A kind of preparation method of micro-nano composite structure on the surface of titanium material

A technology of micro-nano composite structure and micro-nano structure, which is applied in the field of metal biomaterials and biomaterials, can solve the problems of unfavorable cell adhesion, easy peeling, and low bonding strength of the matrix, and achieve bioactivity and biocompatibility. Membrane Increased base binding force, beneficial to osseointegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Micro-nano structures are prepared on pure titanium with a size of 10mm*10mm*1mm.

[0033] (1) Polish the pure titanium sheet with a specification of 10mm*10mm*1mm with 800#, 1000#, 1500#, 2000# water-resistant silicon carbide sandpaper in sequence, then ultrasonically clean it in acetone and ethanol for 30 minutes, and finally use Deionized water cleaning, drying;

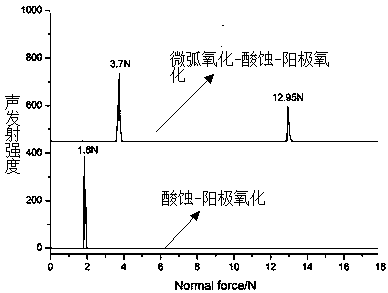

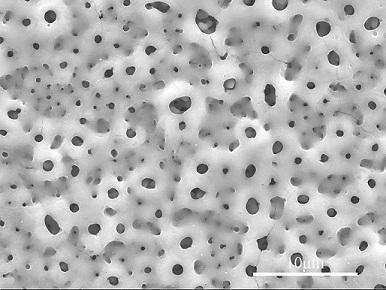

[0034] (2) Micro-arc oxidation: use a pulsed DC power supply to perform micro-arc oxidation on the polished pure titanium titanium material. The oxidation conditions are: voltage 270V, pulse frequency 100Hz, duty cycle 50%, electrode spacing 4cm, with 0.2 A mixed solution of mol / L calcium acetate and 0.1mol / L sodium dihydrogen phosphate was used as the electrolyte, the oxidation time was 3 minutes, and the temperature of the electrolyte was controlled at 15°C. After the micro-arc oxidation was completed, the titanium material was cleaned with deionized water and dried. , under the field emission scanning e...

Embodiment 2

[0042] Micro-nano structures are prepared on pure titanium with a size of 10mm*10mm*1mm.

[0043] (1) Polish the pure titanium sheet with a specification of 10mm*10mm*1mm with 800#, 1000#, 1500#, 2000# water-resistant silicon carbide sandpaper in sequence, then ultrasonically clean it in acetone and ethanol for 30 minutes, and finally use Deionized water cleaning, drying;

[0044] (2) Micro-arc oxidation: Use a pulsed DC power supply to perform micro-arc oxidation on the polished pure titanium titanium material. The oxidation conditions are: voltage 300V, pulse frequency 100Hz, duty cycle 50%, electrode spacing 4cm, with 0.2 A mixed solution of mol / L calcium acetate and 0.1mol / L sodium dihydrogen phosphate is used as the electrolyte, the oxidation time is 3 minutes, and the temperature of the electrolyte is controlled at 15°C. After the micro-arc oxidation is completed, the titanium material is cleaned with deionized water and dried;

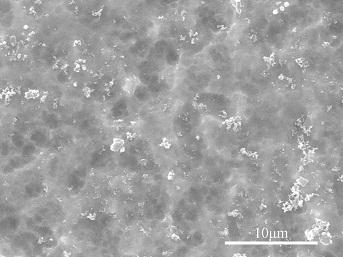

[0045] (3) Acid etching: Corrode the tit...

Embodiment 3

[0049] Micro-nano structures are prepared on pure titanium with a size of 10mm*10mm*1mm.

[0050] (1) Polish the pure titanium sheet with a specification of 10mm*10mm*1mm with 800#, 1000#, 1500#, 2000# water-resistant silicon carbide sandpaper in sequence, then ultrasonically clean it in acetone and ethanol for 30 minutes, and finally use Deionized water cleaning, drying;

[0051] (2) Micro-arc oxidation: Use a pulsed DC power supply to perform micro-arc oxidation on the polished titanium material. The oxidation conditions are: voltage 330V, pulse frequency 100Hz, duty cycle 50%, electrode spacing 4cm, and 0.2 A mixed solution of mol / L calcium acetate and 0.1mol / L sodium dihydrogen phosphate is used as the electrolyte, the oxidation time is 3 minutes, and the temperature of the electrolyte is controlled at 15°C. After the micro-arc oxidation is completed, the titanium material is cleaned with deionized water and dried;

[0052] (3) Acid etching: Corrode the titanium material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com