Method for preparing chrysotile nano fiber

A technology of fiber serpentine and nanofibers, which is applied in the field of preparation of fiber serpentine nanofibers, can solve the problem that the fiber serpentine fibers cannot be peeled off the nanofibers, etc., and achieves the effects of good crystallinity, labor saving and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

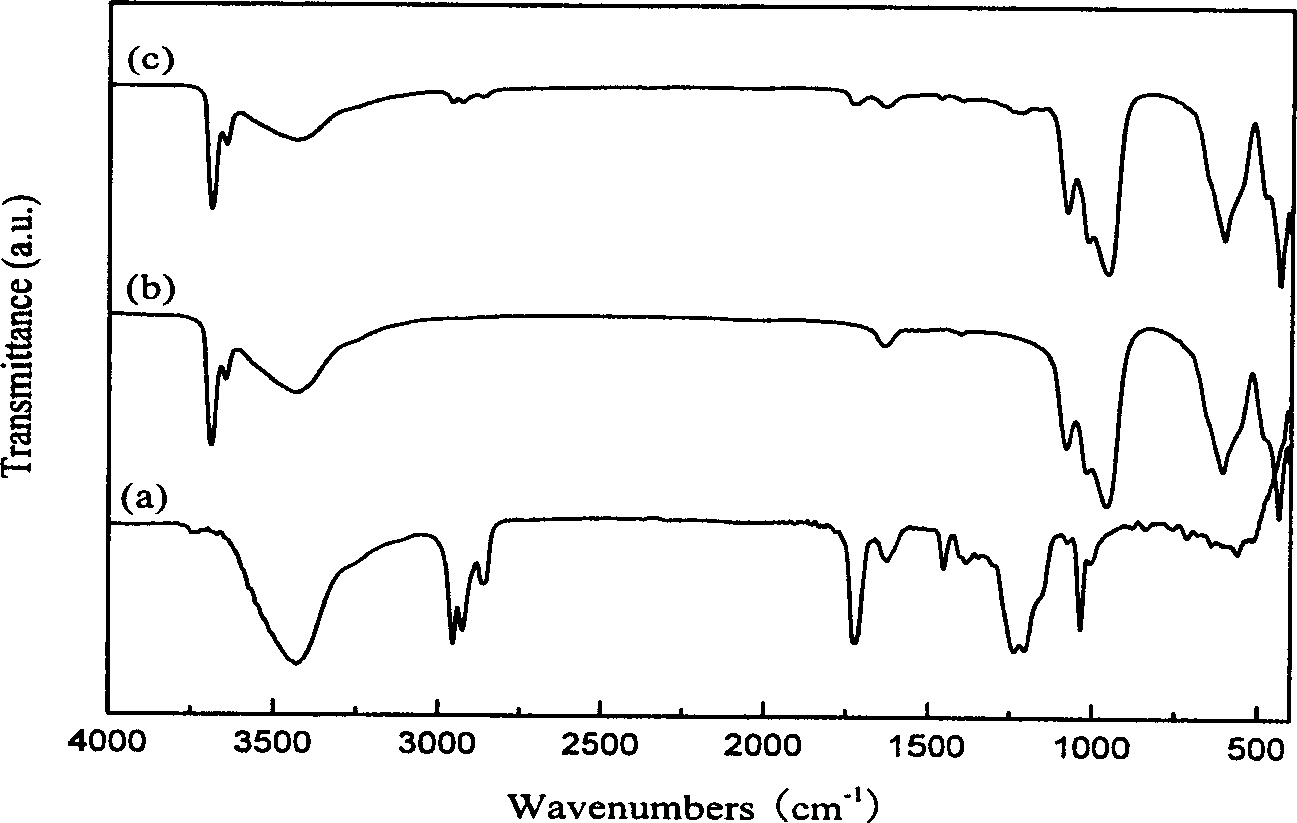

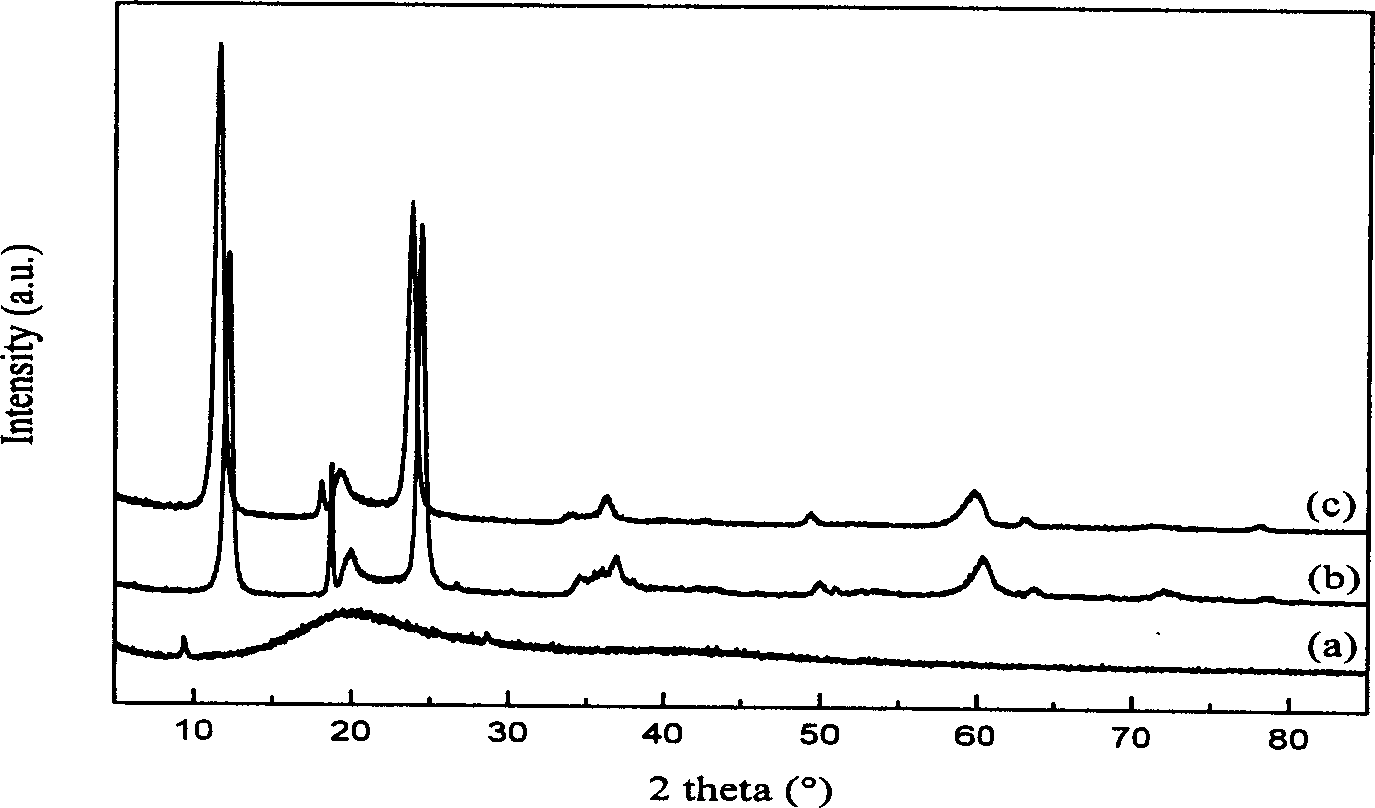

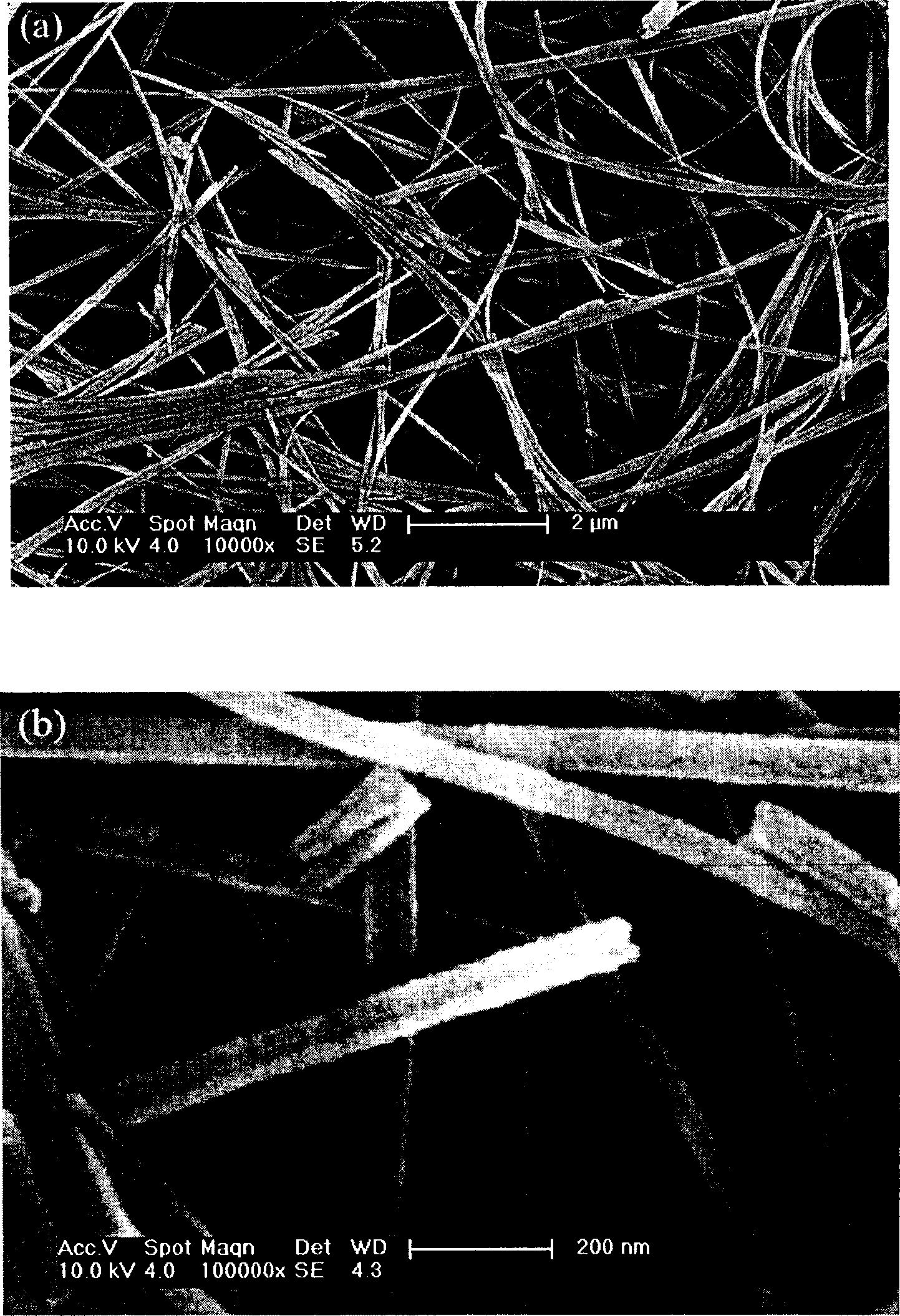

[0021] After purifying grade 6 chrysotile from a certain asbestos mine, take 10 g and add it into an aqueous solution with a volume of 1 L and a concentration of sodium diisooctyl sulfosuccinate of 2 g / L, and soak for 2 hours (note: diisooctyl sulfosuccinate The critical micelle concentration of sodium bicarbonate is about 1.08g / L; its saturated adsorption capacity on the surface of chrysotile is about 180mg / g). Then use a high-speed emulsifying disperser to stir and disperse the above mixed solution for 60 minutes at a speed of 6000 rpm. After the dispersion is completed, a yellow-white homogeneous asbestos colloidal solution will be obtained. The solution is centrifuged at 4000 rpm for 1 min to remove a small amount of fine impurities contained therein. The color of the asbestos colloidal solution after centrifugation is whiter and brighter, and it is filtered by suction, and washed repeatedly with distilled water for 6 to 8 times to remove the sodium diisooctyl sulfosuccina...

Embodiment 2

[0023] After purifying the asbestos tailings of an asbestos mine, take 10 g and add it to an aqueous solution with a volume of 1 L and a concentration of sodium dodecylbenzenesulfonate of 1.6 g / L, soak for 2 hours (note: dodecylbenzenesulfonic acid The critical micelle concentration of sodium is about 557mg / L; its saturated adsorption capacity on the surface of chrysotile is about 141mg / g). Then use a high-speed emulsifying disperser to stir and disperse the above mixed solution for 60 minutes at a speed of 6000 rpm. After the dispersion is completed, an off-white homogeneous asbestos colloidal solution will be obtained. The solution is centrifuged at 4000 rpm for 1 min to remove a small amount of fine impurities contained therein. The color of the asbestos colloidal solution after centrifugation is whiter and brighter. It is suction filtered and washed repeatedly with distilled water for 6 to 8 times to remove the sodium dodecylbenzenesulfonate remaining in the solution or ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com