Method for preparing magnetic chrysotile nanotube

A chrysotile and nanotube technology, which is applied in the field of preparation of chrysotile nanotubes, can solve problems affecting performance, weak magnetism, etc., and achieve the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

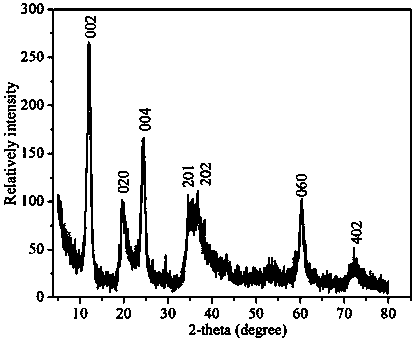

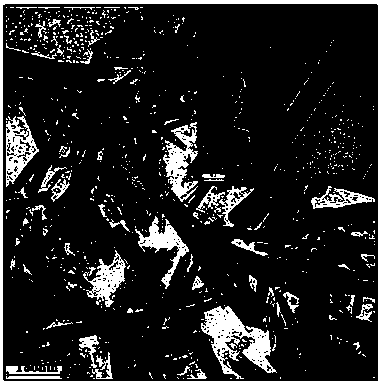

[0027] 1. Add precipitated hydrated silica, industrial light magnesia, ferrous sulfate and water into the reaction kettle, stir and mix evenly under the protection of nitrogen to obtain a mixed solution; the mass concentration of silicon dioxide in the mixed solution is 4.5%. The mass concentration of magnesium is 2.3%, and the mass concentration of ferrous iron is 3.2%.

[0028] 2. Add sodium hydroxide solution to the mixture to adjust the pH value to 11, then move it to a high-pressure reactor, react at 240°C for 24 hours under airtight conditions, and then filter it, and wash the filter cake with water until the pH value is 7.6 , and then dried at 105° C. for 2 hours to obtain magnetic chrysotile nanotubes, whose saturation magnetization was measured to be 5.48 emu / g.

Embodiment 2

[0030] 1. Add fumed white carbon black, hydrated basic magnesium carbonate, ferrous chloride and water into the reaction kettle, stir and mix evenly under the protection of nitrogen to obtain a mixed solution; the mass concentration of silicon dioxide in the mixed solution is 8.9%, oxidized The mass concentration of magnesium is 2.9%, and the mass concentration of ferrous iron is 8.1%.

[0031] 2. Add sodium hydroxide solution to the mixed solution to adjust the pH value to 13, then move it to a high-pressure reactor, react at 190°C for 72 hours under airtight conditions, and then filter it, and wash the filter cake with clean water until the pH value is 7.9 , and then dried at 60° C. for 10 hours to obtain magnetic chrysotile nanotubes, whose saturation magnetization was measured to be 12.78 emu / g.

Embodiment 3

[0033] 1. Add silica sol, flame-retardant magnesium hydroxide, ferrous oxalate and water into the reaction kettle, stir and mix evenly under nitrogen protection to obtain a mixed solution; the mass concentration of silicon dioxide in the mixed solution is 21.4%, and that of magnesium oxide The mass concentration is 19.2%, and the mass concentration of ferrous iron is 3.0%.

[0034] 2. Add sodium hydroxide solution to the mixed solution to adjust the pH value to 12, then move it to a high-pressure reactor, react at 210°C for 48 hours under airtight conditions, and then filter it, and wash the filter cake with water until the pH value is 8.3 , and then dried at 80° C. for 6 hours to obtain magnetic chrysotile nanotubes, whose saturation magnetization was measured to be 8.03 emu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com