Hydrophilic diaphragm and battery containing hydrophilic diaphragm

A technology of hydrophilic and hydrophilic polymers, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of battery short circuit, electrode particle penetration, etc., to improve cycle life, and the process is simple and easy , Improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a1

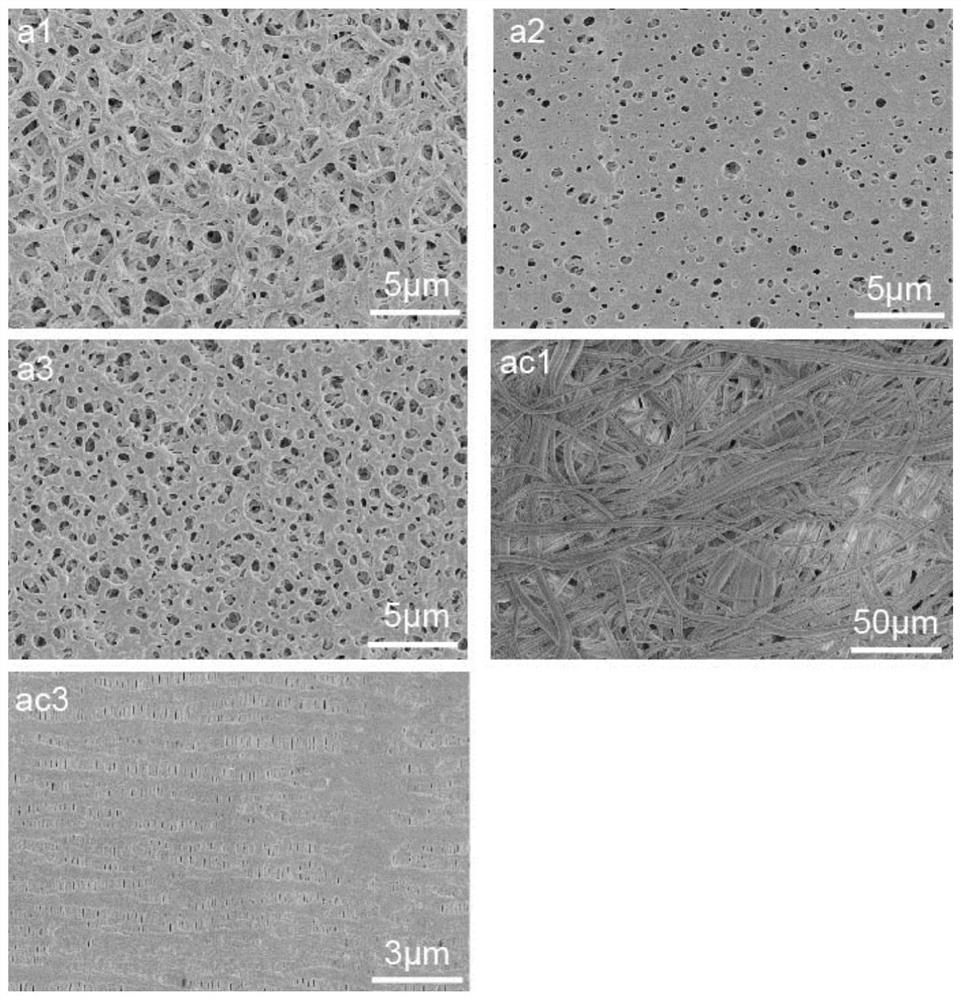

[0041]A hydrophilic diaphragm having a microporous membrane containing a hydrophilic polymer material; the hydrophilic diaphragm has a pore diameter of 0.2 um, a thickness of 0.12 mm, a porosity of 68%; The hydrophilic polymer material is nylon 6; Example A1 The hydrophilic diaphragm is recorded as A1.

Embodiment a2

[0043]A hydrophilic diaphragm having a microporous membrane containing a parental polymer material; the hydrophilic diaphragm has a pore diameter of 0.2 um, a thickness of 0.12 mm, a porosity of 71%; The aqueous polymer material is a polyether sulfone; Example A2 The hydrophilic diaphragm is rejected as A2.

Embodiment a3

[0045]A hydrophilic diaphragm having a microporous film containing a parental polymer material; the hydrophilic diaphragm has a pore diameter of 0.2 um, a thickness of 0.12 mm, a porosity of 75%; The hydrophilic polymer material is nitrate cellulose; Example A3 The hydrophilic diaphragm is recorded as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com