Water-based foaming pore regulator suitable for synthetic leather

A technology of adjusting agent and synthetic leather, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of low safety, unfavorable cell adjustment, generation of small cells, etc., to improve the embossing effect and accelerate the solidification speed , the effect of preventing agglomeration or settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 0.5 parts of N-methylolacrylamide, 0.5 parts of nano-ceramic rubber powder and 0.05 parts of aminotrimethylene phosphonic acid to 5 parts of sodium polyacrylate, and raise the temperature to 75- Keep mixing at 80°C for 15 minutes, continue to heat up to 120-125°C at a heating rate of 5°C / min, keep mixing for 15 minutes, and then cool naturally to room temperature to obtain material I;

[0025] (2) Add 20 parts of nano-titanium dioxide modified poloxamer and 5 parts of hydroxypropyl methylcellulose to 100 parts of water, stir and dissolve completely and let stand for 30 minutes, then add 3 parts of hydrolyzed polymaleic anhydride and 1 part of seaweed Na2SO4, and heated to reflux state at a heating rate of 5°C / min and kept mixed for 10 minutes, then naturally cooled to room temperature to obtain material II;

[0026] (3) Add 0.15 parts of sodium gluconate and 0.15 parts of L-calcium aspartate to material II, mix well, then microwave at a microwave frequency of 24...

Embodiment 2

[0030] (1) Add 0.5 parts of N-methylolacrylamide, 0.5 parts of nano-ceramic rubber powder and 0.1 parts of aminotrimethylene phosphonic acid to 3 parts of sodium polyacrylate, and raise the temperature to 75- Keep mixing at 80°C for 15 minutes, continue to heat up to 120-125°C at a heating rate of 5°C / min, keep mixing for 15 minutes, and then cool naturally to room temperature to obtain material I;

[0031] (2) Add 20 parts of nano-titanium dioxide-modified poloxamer and 5 parts of hydroxypropyl methylcellulose to 100 parts of water, stir and dissolve completely and let stand for 30 minutes, then add 2 parts of hydrolyzed polymaleic anhydride and 1 part of seaweed Na2SO4, and heated to reflux state at a heating rate of 5°C / min and kept mixed for 10 minutes, then naturally cooled to room temperature to obtain material II;

[0032](3) Add 0.3 part of sodium gluconate and 0.1 part of L-calcium aspartate to material II, mix well, then microwave at microwave frequency 2450MHz, outp...

Embodiment 3

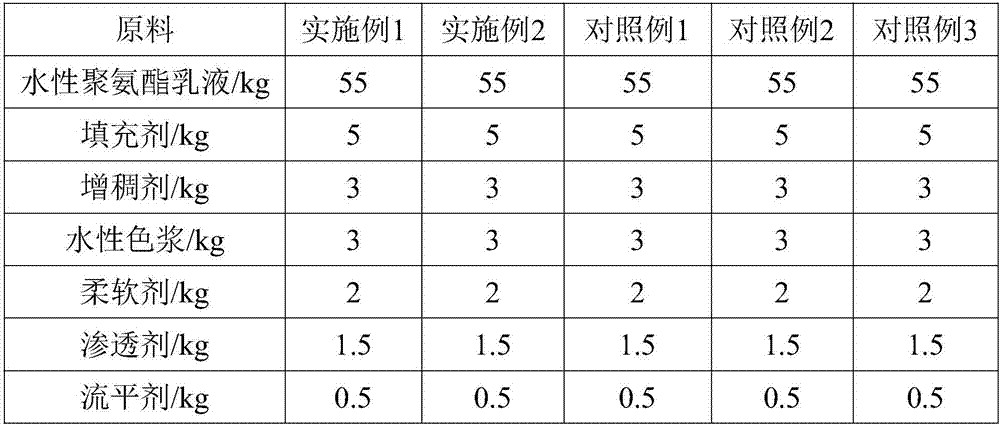

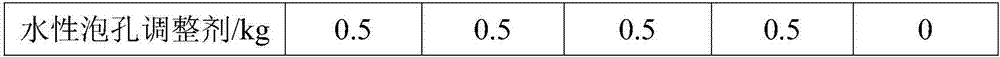

[0046] The water-based cell regulator made by the same amount of embodiment 1, embodiment 2, comparative example 1, and comparative example 2 is added in the water-based polyurethane slurry (as shown in table 1), and the contrast without adding the water-based cell regulator is set Example 3, and through the same processing technology to make polyurethane synthetic leather, then the performance of the synthetic leather is measured, the results are shown in Table 2.

[0047] Table 1 Waterborne polyurethane slurry formulation

[0048]

[0049]

[0050] Table 2 Performance of processed synthetic leather

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com