Automatic paint spraying device for hardware processing

A hardware and paint storage technology, which is applied in the field of automatic paint spraying devices for hardware processing, can solve the problems that the paint liquid is easy to fly to the surrounding operators, the adverse effects of the staff, and the protruding particles are easy to be produced, so as to avoid paint splashing , Anti-dust paint splash, accelerate the effect of solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

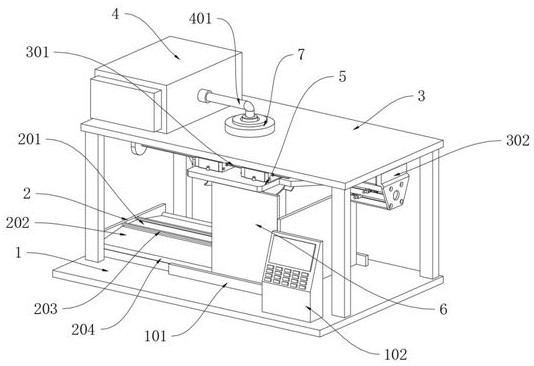

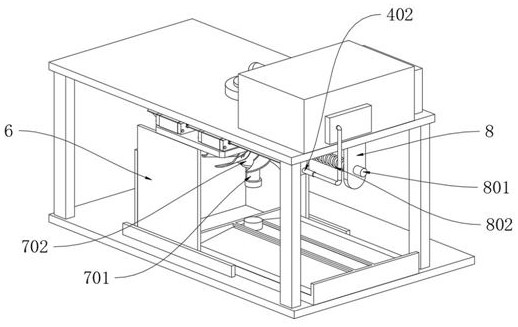

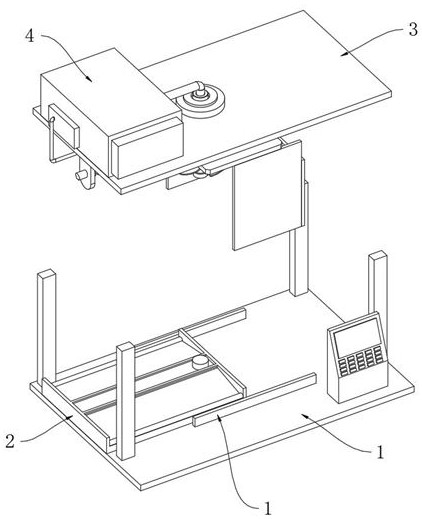

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033]The invention provides an automatic painting device for hardware processing, which includes a base 1; a paint spraying platform 2 is fixed and installed horizontally at the middle left of the top plane of the base 1; a top plate is fixed and installed on the upper end of the base 1 through four supporting columns at the corners 3. The front edge of the top plate 3 is located behind the front edge of the base 1, while the rear edge of the top plate 3 is aligned with the rear edge of the base 1; the middle of the top plane of the top plate 3 is fixed to the left A paint storage mechanism 4 is installed; the paint storage mechanism 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com