Casting process of two-stage planet carrier of climbing machine for ocean platform

An offshore platform and casting process technology, applied in the field of metal casting, can solve the problems of high dimensional accuracy, high surface quality requirements, high smelting process and operation difficulty, and difficulty in guaranteeing the internal quality of castings. The effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

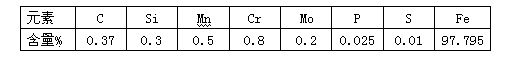

[0031] The secondary planetary carrier casting of the offshore platform climbing machine is made of ZG35Gr1Mo material, and the main elements and contents of the material are as follows:

[0032]

[0033] The secondary planetary carrier casting of the offshore platform climbing machine is obtained by integral casting molding process and heat treatment, including the following processing steps:

[0034] (a) Molten steel smelting: putting the ZG35Gr1Mo material into an electric arc furnace to smelt into molten steel;

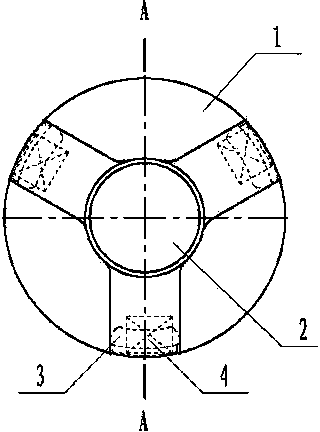

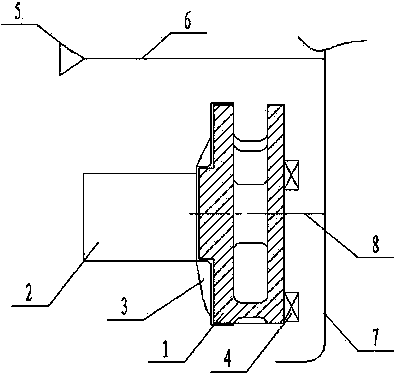

[0035] (b) Casting process: The sand mold upper box and the sand mold lower box constitute the casting cavity. A core box is placed in the middle of the cavity, and then the pre-casting preparation is carried out according to the above method. One box casts 2 pieces, pouring 950kg of molten steel, and the pouring temperature is 1560°C, the pouring time is 20s, the box is loosened after pouring for 1 hour, and the mold is demoulded after 24 hours of heat preserv...

Embodiment 2

[0039] The secondary planetary carrier casting of the offshore platform climbing machine is made of ZG35Gr1Mo material, and the main elements and contents of the material are as follows:

[0040]

[0041] The secondary planetary carrier casting of the offshore platform climbing machine is obtained by integral casting molding process and heat treatment, including the following processing steps:

[0042] (a) Molten steel smelting: putting the ZG35Gr1Mo material into an electric arc furnace to smelt into molten steel;

[0043] (b) Casting process: The sand mold upper box and the sand mold lower box constitute the casting cavity. A core box is placed in the middle of the cavity, and then the pre-casting preparation is carried out according to the above method. One box casts 2 pieces, pouring 950kg of molten steel, and the pouring temperature is 1540°C, the pouring time is 25s, the box is loosened after pouring for 1 hour, and the mold is demoulded after 24 hours of heat preserv...

Embodiment 3

[0047] The secondary planetary carrier casting of the offshore platform climbing machine is made of ZG35Gr1Mo material, and the main elements and contents of the material are as follows:

[0048]

[0049] The secondary planetary carrier casting of the offshore platform climbing machine is obtained by integral casting molding process and heat treatment, including the following processing steps:

[0050] (a) Molten steel smelting: putting the ZG35Gr1Mo material into an electric arc furnace to smelt into molten steel;

[0051] (b) Casting process: The sand mold upper box and the sand mold lower box constitute the casting cavity. A core box is placed in the middle of the cavity, and then the pre-casting preparation is carried out according to the above method. One box casts 2 pieces, pouring 950kg of molten steel, and the pouring temperature is 1550°C, the pouring time is 24s, the box is loosened after pouring for 1 hour, and the mold is demoulded after 24 hours of heat preserv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com