SPME extracting fiber of porous organic framework coating and preparation method of SPME extracting fiber

A technology of organic framework and extraction fiber, which is applied in the field of porous organic framework coated SPME extraction fiber and its preparation, can solve the problem of no aromatic type, etc., and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

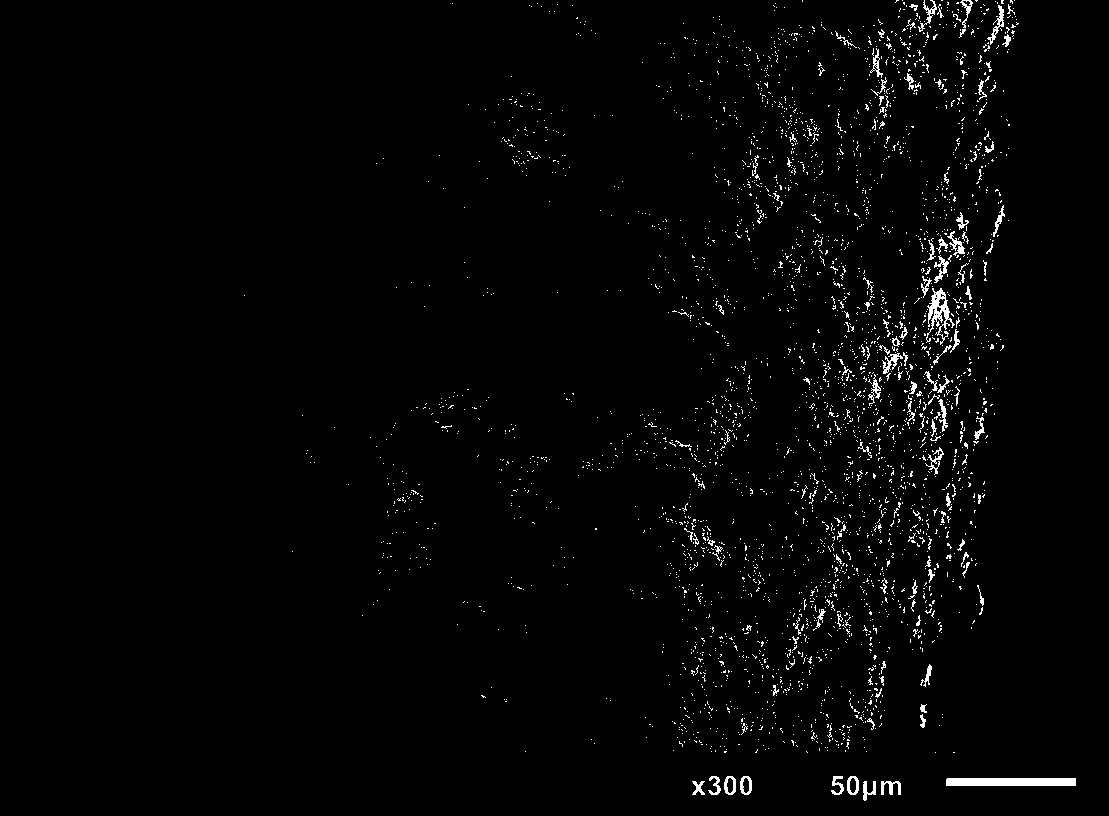

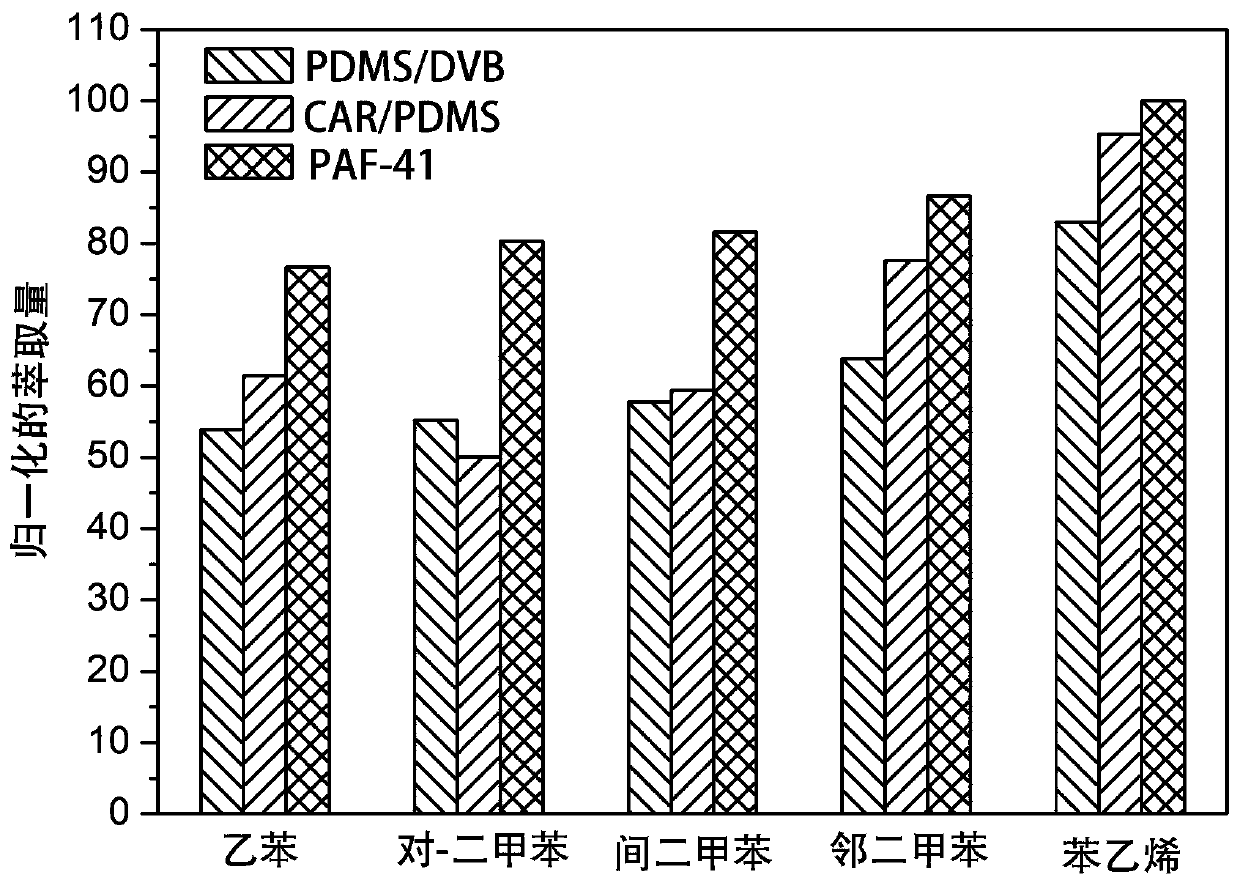

Image

Examples

Embodiment 1

[0035] A kind of preparation method of the SPME extraction fiber of porous organic framework coating, comprises the following steps:

[0036] (1) Under nitrogen protection, add anhydrous aluminum chloride (3.5mmol) into a 100mL round bottom flask, and then inject 40mL of anhydrous CHCl 3 , and stirred at 60 °C for 3 hours.

[0037] (2) Dissolve 1,3,5-triphenylamine (1.5mmol) in 20mL anhydrous CHCl 3 .

[0038] (3) Inject the solution of step 2 into the system of step 1, and stir and react at 60° C. for 24 hours.

[0039] (4) After the reaction is completed, and the temperature of the system is lowered to room temperature, filter and wash with hydrochloric acid (1mol L -1 ), methanol, and acetone to wash and clean the product 3 times. Subsequently, the product was subjected to Soxhlet extraction with ethanol, tetrahydrofuran and chloroform in sequence, and the extraction time was 2 days.

[0040] (5) PAF-41 was obtained under vacuum at 80°C for 12 hours.

[0041] (6) Soak...

Embodiment 2

[0046] A kind of preparation method of the SPME extraction fiber of porous organic framework coating, comprises the following steps:

[0047] (1) Under the protection of nitrogen, anhydrous FeCl 3 (4.5mmol) was added to a 100mL round bottom flask, followed by injection of 40mL of anhydrous CHCl 3 , and stirred at 60 °C for 3 hours.

[0048] (2) Dissolve 1,3,5-triphenylamine (1.5mmol) in 20mL anhydrous CHCl 3 .

[0049] (3) Inject the solution of step 2 into the system of step 1, and stir and react at 60° C. for 24 hours.

[0050] (4) After the reaction is completed, and the temperature of the system is lowered to room temperature, filter and wash with hydrochloric acid (1mol L -1 ), methanol, and acetone to wash and clean the product 3 times. Subsequently, the product was subjected to Soxhlet extraction with ethanol, tetrahydrofuran and chloroform in sequence, and the extraction time was 2 days.

[0051] (5) PAF-41 was obtained under vacuum at 80°C for 12 hours.

[0052...

Embodiment 3

[0057] A kind of preparation method of the SPME extraction fiber of porous organic framework coating, comprises the following steps:

[0058] (1) Under the protection of nitrogen, the anhydrous CuCl 2 (0.8mmol) was added to a 200mL round bottom flask, followed by injection of 40mL of anhydrous CHCl 3 , and stirred at 75 °C for 3 hours.

[0059] (2) Dissolve 1,3,5-triphenylamine (10mmol) in 50mL anhydrous CHCl 3 .

[0060] (3) Inject the solution of step 2 into the system of step 1, and stir and react at 70° C. for 72 hours.

[0061] (4) After the reaction is finished, and the temperature of the system drops to room temperature, filter and wash with hydrochloric acid (3mol·L -1 ), methanol, and acetone to wash and clean the product 3 times. Subsequently, the product was subjected to Soxhlet extraction with ethanol, tetrahydrofuran and chloroform in sequence, and the extraction time was 1 day.

[0062] (5) PAF-41 was obtained under vacuum at 80°C for 12 hours.

[0063] (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com