Two-step method for preparing graphene oxide material loaded with quaternary ammonium salt groups and its application

A quaternary ammonium salt group, graphene technology, applied in chemical instruments and methods, botanical equipment and methods, applications, etc., can solve the problems of low adsorption performance and hydrophilic performance, destroying graphene nanostructures, etc. High hydrophilicity, stable physical and chemical properties, good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

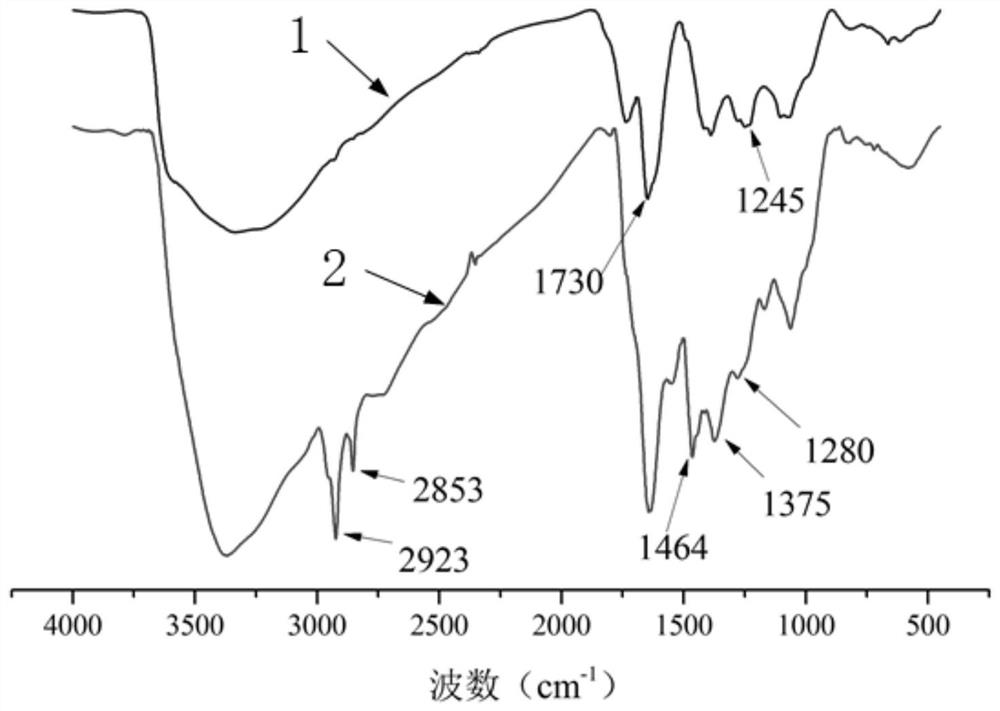

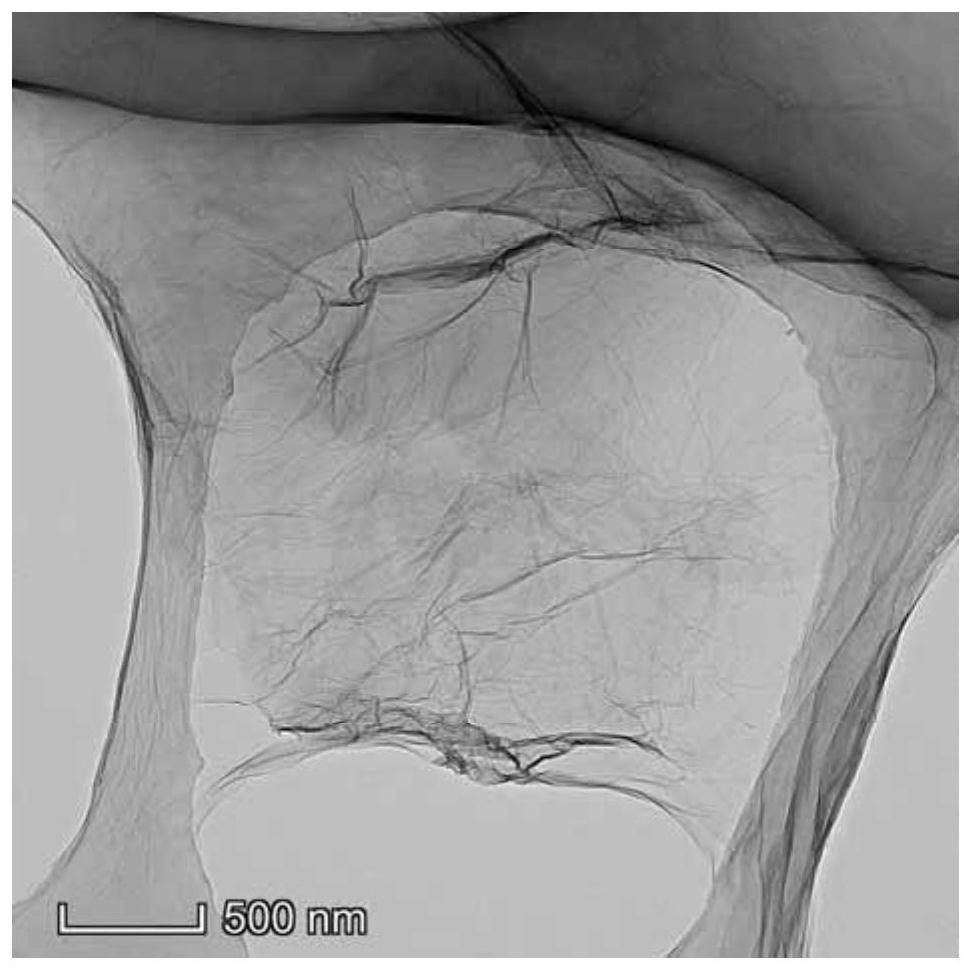

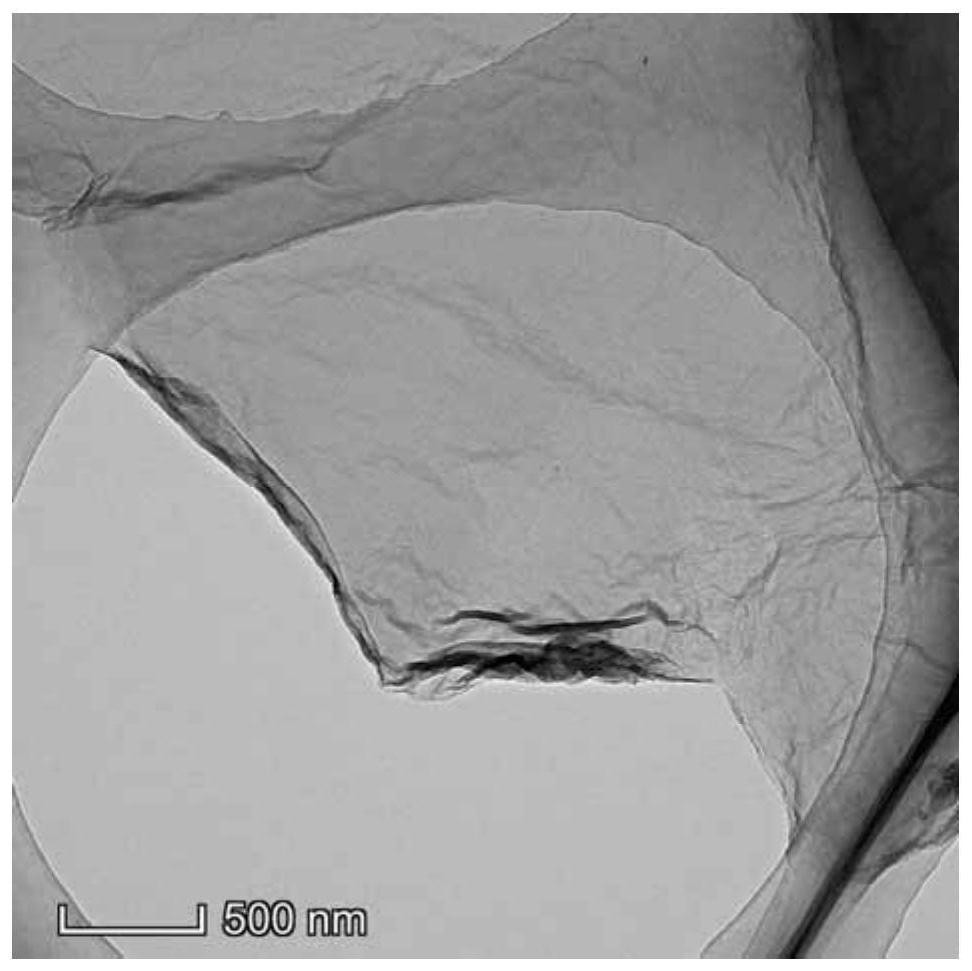

[0026] Specific embodiment one: the method for preparing graphene oxide material loaded with quaternary ammonium salt group by two-step method in this embodiment is implemented according to the following steps:

[0027] 1. Grafting tertiary amine groups on the surface of graphene oxide: Dissolving graphene oxide in a solvent and ultrasonically dispersing to obtain a homogeneous and stable graphene oxide suspension, then adding a tertiary amination modifier for tertiary amination modification Reaction, collecting solid-phase reactants, centrifuging and drying, to obtain graphene oxide loaded with tertiary amine groups;

[0028] 2. Quaternization of tertiary amine groups: Dissolve the graphene oxide loaded with tertiary amine groups obtained in step 1 in a solvent to obtain a suspension of graphene oxide loaded with tertiary amine groups, and then add quaternized ammonium The quaternary ammonium modification reaction is carried out, the reactants are collected, and after centrif...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the solvent described in step one and step two is dimethyl sulfoxide, acetone, cyclohexane, chloroform, NN dimethylformamide, NN two Methylacetamide, N-methylpyrrolidone, water, methanol, absolute ethanol, petroleum ether or tetrahydrofuran.

[0033] In this embodiment, the cleaning solution used in centrifugal cleaning is also dimethyl sulfoxide, acetone, cyclohexane, chloroform, NN dimethylformamide, NN dimethylacetamide, N-methylpyrrolidone, water, methanol , ethanol, petroleum ether or tetrahydrofuran.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molar ratio of graphene oxide to tertiary amination modifier in step 1 is 1:1-1:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com