Special-shaped inner and outer cover assembly device

A technology for assembling devices and outer covers, which is applied in metal processing, household components, metal processing equipment, etc., to achieve the effect of avoiding loose joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

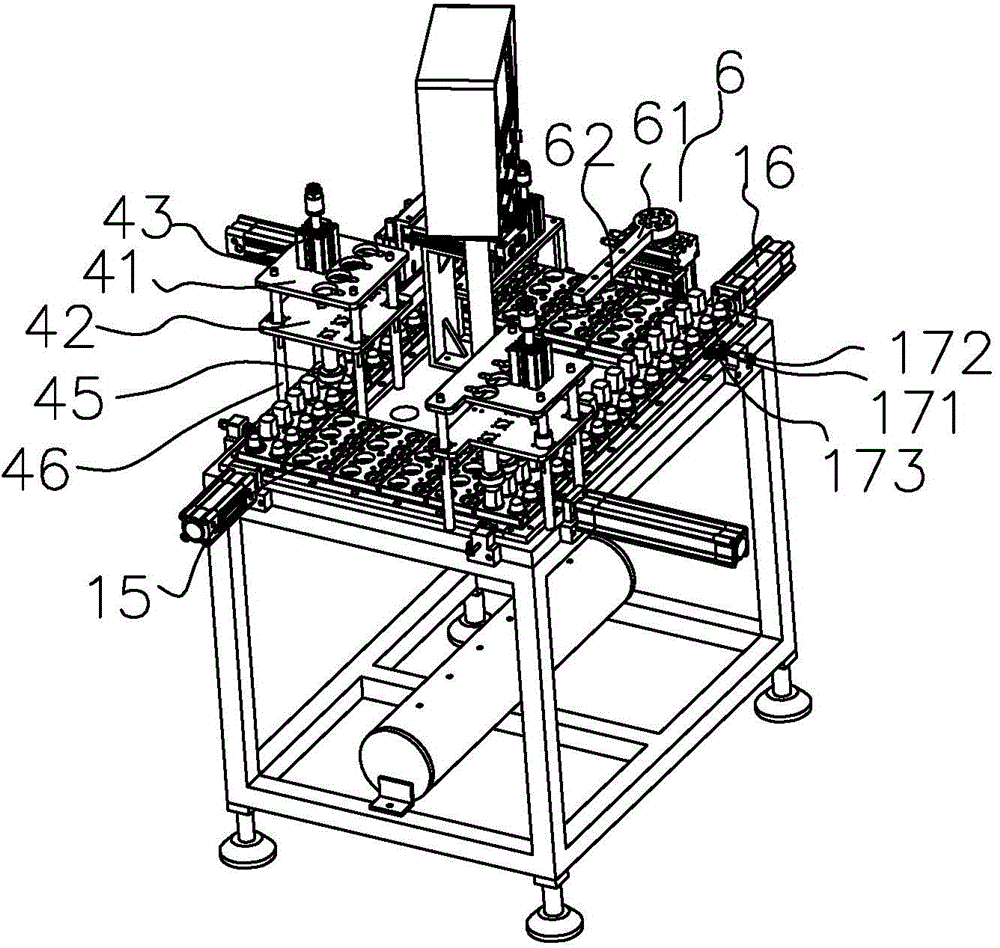

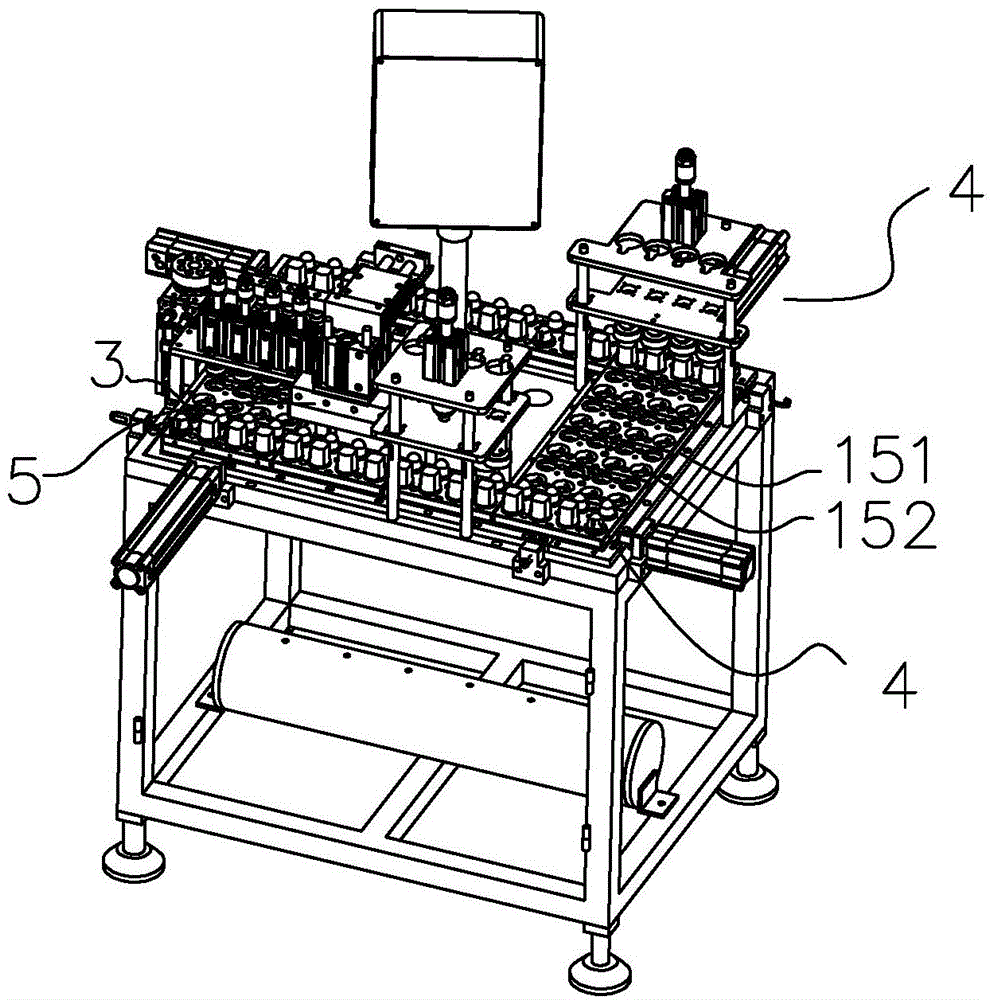

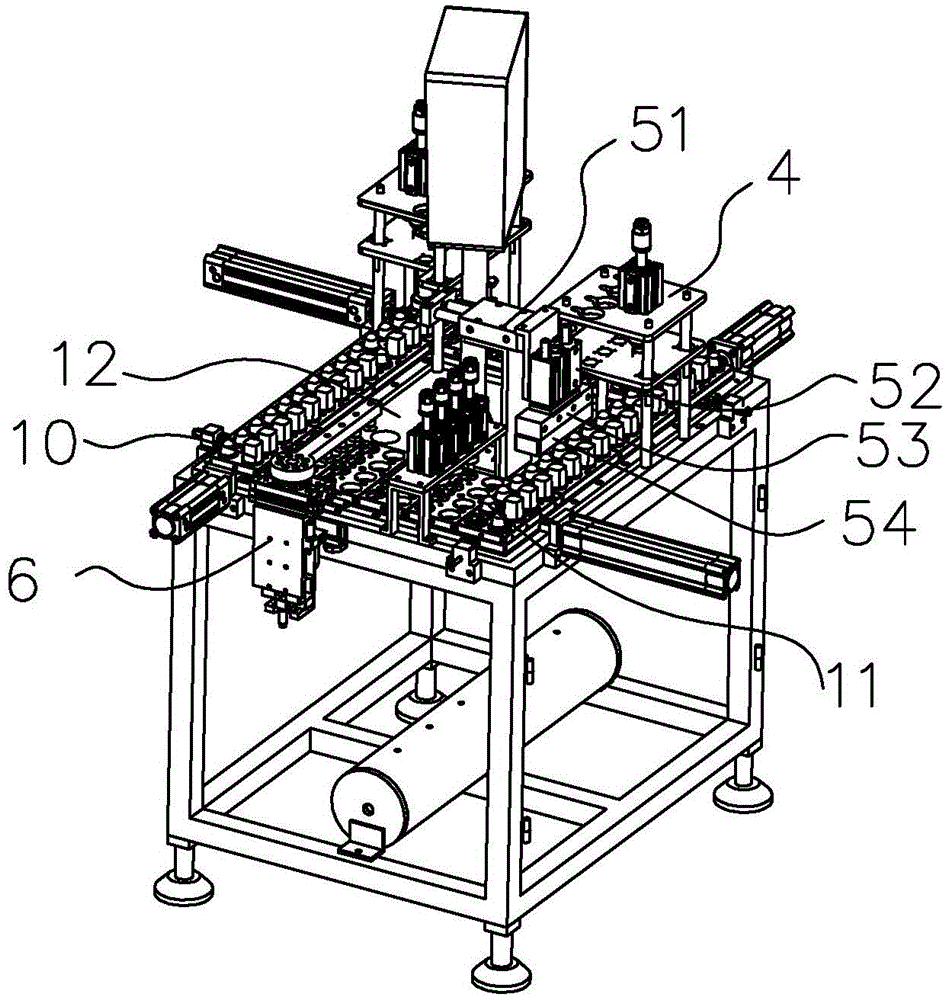

[0018] Please refer to Figure 1 to Figure 20 , the special-shaped inner and outer cover assembly device in the figure includes a panel 12 with a square annular groove, a thrust cylinder group composed of four thrust cylinders 16 and distributed at the corner edge of the panel 12, a plurality of square sliders 15 The slider group constituted, an outer cover clamp 2, an inner cover clamp 3, an outer cover rotation positioning mechanism 4, an inner cover rotation positioning mechanism, an inner and outer cover adsorption mechanism 5, and an inner and outer cover pressing mechanism 6. Wherein the main panel 12 is to provide movement space for the movement of the slider 15; the thrust cylinder group is to provide power to make the slider 15 slide in the annular groove of the panel 12; the slider group is used to place the outer cover fixture 2 and the inner cover fixture 3 The outer cover fixture 2 is used to accurately position the outer cover 10; the inner cover fixture 3 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com