Proton exchange membrane fuel cell stainless steel bipolar plate and method for preparing same

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of difficult precise control of implanted ion concentration and depth, unfavorable mass production, and many processes, etc., to achieve Improved corrosion resistance, easy control of coating composition and depth, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The base material of the bipolar plate is austenitic stainless steel, and its chemical composition is C≤0.03, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni: 12.0-15.0, Cr: 16.0-18.0, Mo: 2.0 -3.0, the remaining content is Fe;

[0029] The formed stainless steel substrate is subjected to pre-treatment processes such as surface cleaning, ultrasonic organic degreasing, and activation. Implant Cr and N ions on the ion implanter, and the vacuum chamber pressure is 2×10 -3 The implantation energies of pa, Cr ion and N ion are 200KeV and 50KeV respectively; the beam intensity is 1.5μAcm -2 , 20μAcm -2 ;Injection volume is 6×10 16 Ionscm -2 , 2×10 17 Ions / cm 2 ; Injection time is 1h. The injection temperature was 120°C. Take it out after cooling in the vacuum furnace for 2 hours.

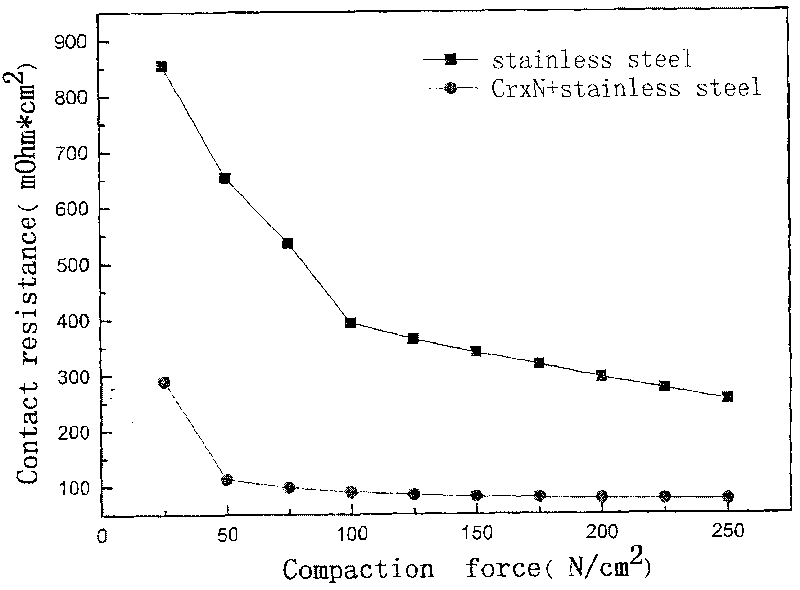

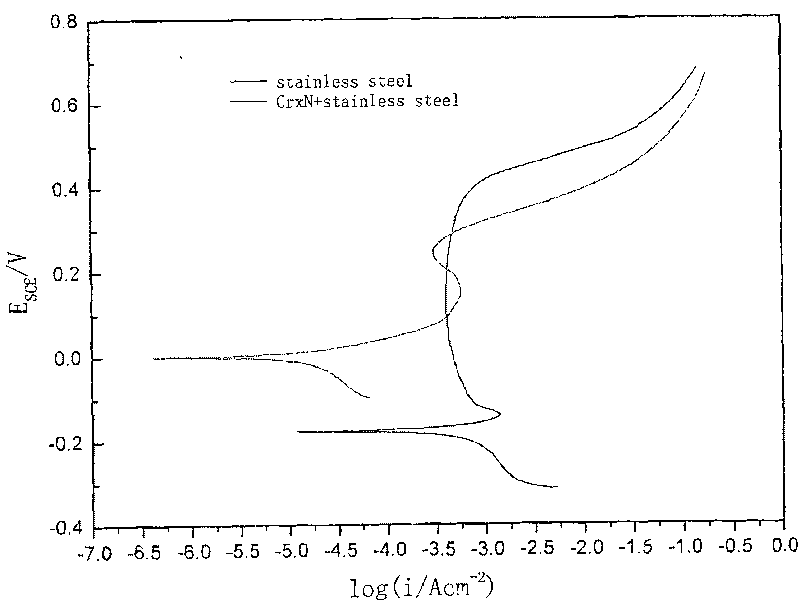

[0030] Performance test: when the pressure is 150Ncm -2 When measured, the contact resistance is 23mΩcm 2 . A saturated calomel electrode was used as a reference electrode, a platinum electrode w...

Embodiment 2

[0032]The base material of the bipolar plate is martensitic stainless steel, and its chemical composition is C≤0.08, Si≤1.00, Mn≤1.00, P≤0.04, S≤0.030, Ni: 12.0-15.0, Cr: 11.0-13.50, and the remaining content is Fe;

[0033] The cleaned and shaped stainless steel substrate was implanted with Cr and N ions on an ion implanter, and the pressure in the vacuum chamber was 1×10 -2 The implantation energies of pa, Cr ion and N ion are 250KeV and 60KeV respectively; the beam intensity is 1.8μAcm -2 , 23μAcm -2 ;Injection volume is 3×10 17 Ions / cm -2 , 3×10 17 Ions / cm 2 ; Injection time is 2h. The injection temperature is 240°C. Take it out after cooling in the vacuum furnace for 2 hours.

[0034] Performance test: when the pressure is 150Ncm -2 When measured, the contact resistance is 25mΩcm 2 . A saturated calomel electrode was used as a reference electrode, a platinum electrode was used as a counter electrode, and the obtained bipolar plate was used as a working electrod...

Embodiment 3

[0036] The base material of the bipolar plate is austenitic stainless steel, and its chemical composition is C≤0.03, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni: 12.0-15.0, Cr: 16.0-18.0, Mo: 2.0 -3.0, the remaining content is Fe;

[0037] The formed stainless steel substrate is subjected to pre-treatment processes such as surface cleaning, ultrasonic organic degreasing, and activation. Implant Cr and N ions on the ion implanter, and the vacuum chamber pressure is 2×10 -3 The implantation energies of pa, Cr ion and N ion are 240KeV and 60KeV respectively; the beam intensity is 2μAcm -2 , 25μAcm -2 ;Injection volume is 3×10 17 Ionscm -2 , 3×10 16 Ions / cm 2; The injection time is 2h. The injection temperature was 200°C. Take it out after cooling in the vacuum furnace for 2 hours.

[0038] Performance test: when the pressure is 150Ncm -2 , the measured contact resistance is 20mΩcm 2 . A saturated calomel electrode was used as a reference electrode, a platinum electrode was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com