Method for preparing poly organic polysulfide/sulfonated graphene conductive composite material

A conductive composite material, sulfonated graphene technology, applied in circuits, electrical components, battery electrodes and other directions, can solve the problems of unsatisfactory cycle stability, poor cycle stability of polyorganic polysulfides, etc., and achieves easy control of product composition, The effect of low environmental pollution and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Sulfonated graphene is obtained by step-by-step reduction of graphite oxide. The process is as follows: put 2g of graphite oxide into 400mL of pH=9-10 aqueous solution, after ultrasonic dispersion for 2h, add 6g of sodium borohydride and stir at 80°C React for 1 hour, centrifuge and rinse with deionized water to obtain partially reduced graphite oxide; then redisperse the partially reduced graphite oxide in 200mL deionized water, add 2.6g of diazonium p-aminobenzenesulfonic acid in an ice-water bath React for 3 hours to introduce sulfonic acid groups; finally, react the above sulfonated product with 30 g of hydrazine hydrate at 100°C for 24 hours to remove residual oxygen-containing groups, wash with deionized water until neutral, and dry. Obtain sulfonated graphene.

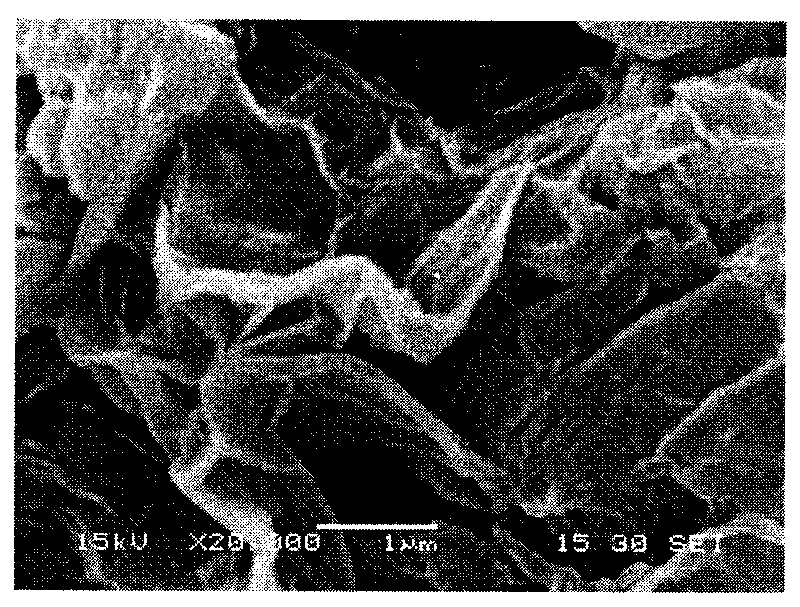

[0032] Dissolve 1.5g of 2,5-dimercapto-1,3,4-thiadiazole monomer in a mixed solution of 100mL deionized water / ethanol (deionized water:ethanol=1:2, volume ratio), and then add 1.5g of sulfonated graphene...

Embodiment 2

[0037]Repeat the process of Example 1 to prepare sulfonated graphene.

[0038] Dissolve 1 g of 2,5-dimercapto-1,3,4-thiadiazole monomer in a mixed solution of 100 mL deionized water / ethanol (deionized water:ethanol=1:2, volume ratio), and then add 0.1 g of sulfonated graphene, after ultrasonication for 15 minutes, slowly add 1.7g of elemental iodine in 25mL of absolute ethanol solution dropwise to the above solution, and stir and react at 40°C for 24 hours; the product is filtered and deionized water After washing with ethanol and drying, the polyorganic polysulfide / graphene conductive composite material is obtained.

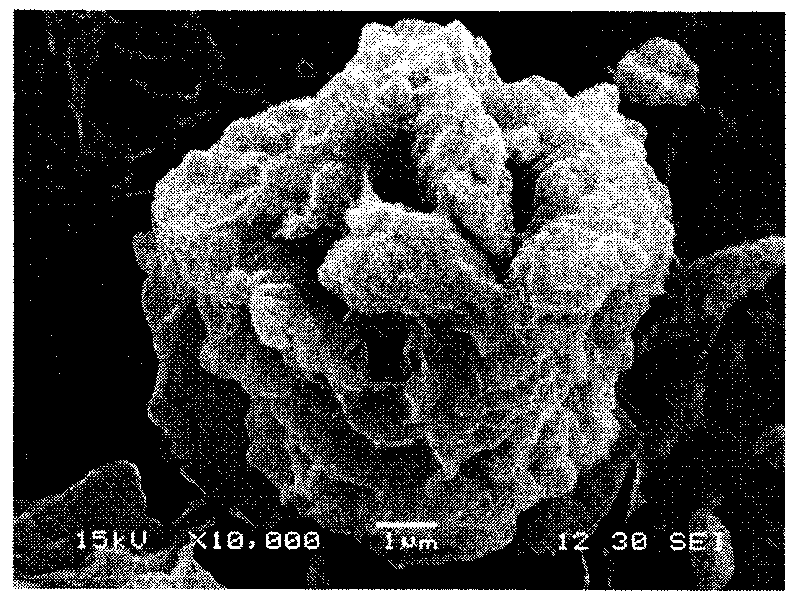

[0039] The morphology of the polyorganopolysulfide / graphene conductive composite is as follows: figure 2 As shown in the SEM pictures of the graphene, it can be seen that poly-2,5-dimercapto-1,3,4-thiadiazole is gathered on the surface and edge of graphene in a submicron sheet structure.

[0040] Using the four-probe technique, the conductivity of the polyorg...

Embodiment 3

[0043] Repeat the process of Example 1 to prepare sulfonated graphene.

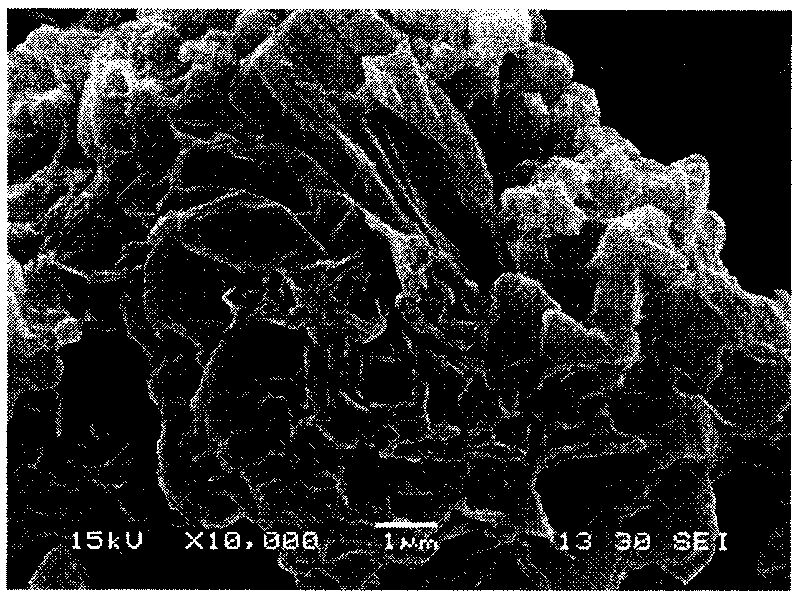

[0044] Dissolve 1 g of 2,5-dimercapto-1,3,4-thiadiazole monomer in a mixed solution of 100 mL deionized water / ethanol (deionized water:ethanol=1:1, volume ratio), and then add 0.05 g of sulfonated graphene, after ultrasonication for 30 minutes, slowly drop 40mL of absolute ethanol solution dissolved with 3.4g of elemental iodine into the above solution, and stir and react at 50°C for 12 hours; the product was filtered and deionized water After washing with ethanol and drying, the polyorganic polysulfide / graphene conductive composite material is obtained.

[0045] Using the four-probe technique, the electrical conductivity of the polyorganopolysulfide / graphene conductive composite was tested to be 0.11 S / cm.

[0046] The button lithium battery using the polyorganopolysulfide / graphene conductive composite material as the positive electrode material was subjected to a charge-discharge cycle test on a LAND C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com