System and method for treatment of organic matters in industrial waste salt by fractional gas stripping by use of hot fluid

An industrial waste salt and thermal fluid technology, applied in the purification of alkali metal chlorides and alkali metal halides, etc., can solve the problems of rising operating costs and declining stability, preventing caking and blocking, large waste salt treatment capacity, etc. The effect of short harmless treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

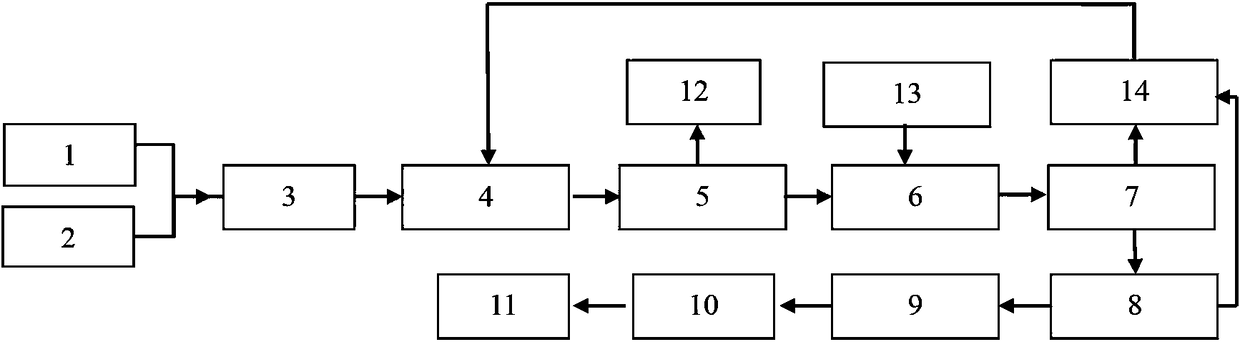

Image

Examples

Embodiment 1

[0024] Polycarbonate waste salt, moisture content 1%, organic matter (TOC) content 3000-6000ppm.

[0025] (1) The propane liquid from the storage tank is heated and vaporized by the vaporizer, then enters the nozzle through the control valve, and then enters the hot blast stove (3), where it burns in contact with the air sent by the blower (2), A thermal fluid is formed.

[0026] (2) The raw material salt warehouse (13) continuously sends industrial waste salt into the secondary gas stripping flue gas pipeline (6) through the belt conveyor, and the flue gas enters the secondary cyclone separator after the salt is preheated to 150-400°C ( 7), the solid salt particles are separated from the flue gas, the solid salt particles enter the intermediate salt bin (14), and the flue gas enters the tail gas treatment device.

[0027] (3) The solid salt in the middle salt bin (14) enters the first-stage air-intensified flue gas pipeline (4) through the belt conveyor, and the high-tempera...

Embodiment 2

[0031] Benzyl chloride waste salt, moisture content 3%, organic matter (TOC) content 6000-10000ppm.

[0032] (1) The liquefied natural gas from the storage tank is heated and gasified by the vaporizer, then enters the nozzle through the control valve, and then enters the hot blast stove (3), where it burns in contact with the air sent by the blower (2), A thermal fluid is formed.

[0033] (2) The raw material salt warehouse (13) continuously sends industrial waste salt into the secondary gas stripping flue gas pipeline (6) through the belt conveyor, and the flue gas enters the secondary cyclone separator after the salt is preheated to 150-400°C ( 7), the solid salt particles are separated from the flue gas, the solid salt particles enter the intermediate salt bin (14), and the flue gas enters the tail gas treatment device.

[0034] (3) The solid salt in the middle salt bin (14) enters the first-stage air-intensified flue gas pipeline (4) through the belt conveyor, and the hig...

Embodiment 3

[0038] Formic acid waste salt, moisture content 5%, organic matter (TOC) content 4000-6000ppm.

[0039] (1) The liquefied synthesis gas from the storage tank is heated and gasified by the vaporizer, then enters the nozzle through the control valve, and then enters the hot blast stove (3), where it burns in contact with the air sent by the blower (2) , forming a thermal fluid.

[0040](2) The raw material salt warehouse (13) continuously sends industrial waste salt into the secondary gas stripping flue gas pipeline (6) through the belt conveyor, and the flue gas enters the secondary cyclone separator after preheating the salt to 150-400 °C ( 7), the solid salt particles are separated from the flue gas, the solid salt particles enter the intermediate salt bin (14), and the flue gas enters the tail gas treatment device.

[0041] (3) The solid salt in the middle salt bin (14) enters the first-stage air-heated flue gas pipeline (4) through the belt conveyor, and the high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com