High-dispersity cobalt-based Fischer-Tropsch synthesis catalyst as well as preparation method and application thereof

A technology of Fischer-Tropsch synthesis and catalysts, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc. It can solve the problems of reduced dispersion of active metals, reduced mechanical strength, inability of active components, and reduced catalyst activity To achieve the effect of improving the degree of dispersion and reduction, controllable composition of chemical elements, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

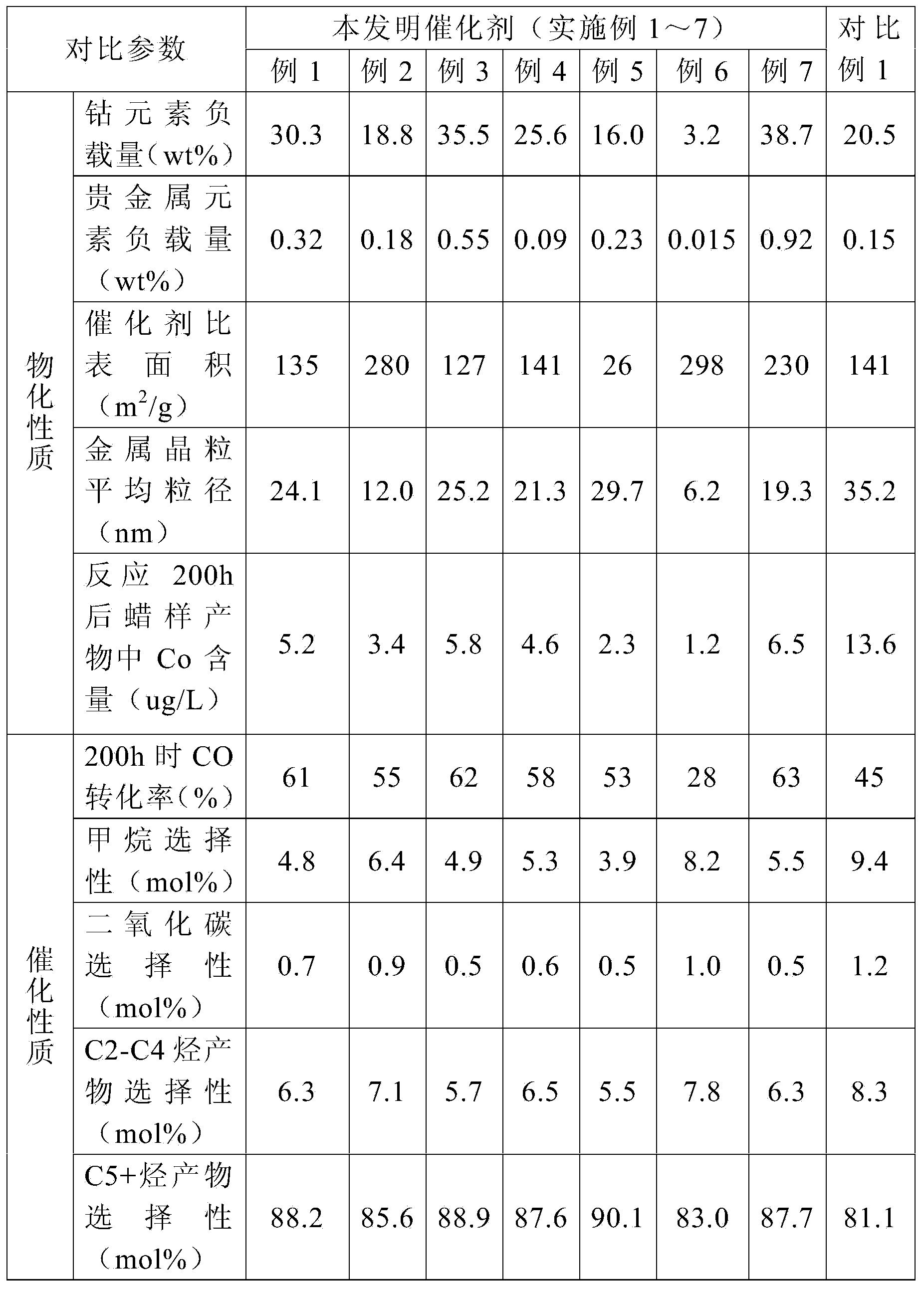

Examples

Embodiment 1

[0034]Step 1), dissolving 270g of cobalt nitrate hexahydrate in 279g of a complexing agent tartaric acid solution with a concentration of 50wt%, then dripping ammonia with a concentration of 18wt%, adjusting the pH value of the solution to 11 to obtain a cobalt complexed metal salt solution and placed in a three-necked bottle for use;

[0035] Step 2), with 100ml alumina carrier (average particle diameter is 85um after pre-calcining treatment, loose bulk ratio is 0.8g / ml, specific surface area is 200m 2 / g gamma-alumina microspheres) are poured into the cobalt complex metal salt solution under stirring state that is made by step 1), then turn on the sonicator and water bath heating, the ultrasonic oscillation power of the sonicator is constant at 2W / cm 2 , the temperature of the cobalt complex metal salt solution is maintained at 60°C;

[0036] Step 3), the concentration of 174g is 80wt% hydrazine hydrate and the equal volume (about 170ml) concentration is the ruthenium tri...

Embodiment 2

[0039] Step 1), dissolving 130g of cobalt chloride hexahydrate in 420g of succinic acid solution with a concentration of 23wt%, then dripping ammonia with a concentration of 25%, adjusting the pH value of the solution to 13 to obtain a cobalt complex metal salt Solution, placed in a three-necked bottle for use;

[0040] Step 2), with 200ml of silica carrier (average particle diameter is 85um after pre-calcining treatment, loose bulk ratio is 0.4g / ml, specific surface area is 430m 2 / g of silicon oxide particles) is poured into the complex metal salt solution under stirring, the ultrasonic instrument and water bath heating are turned on, and the temperature of the cobalt complex metal salt solution is maintained at 80°C;

[0041] Step 3), 182g of hydrazine hydrate with a concentration of 60wt% and an equal volume (about 178ml) of a chloroplatinic acid solution with a concentration of 0.03mol / L were added dropwise to the mixture solution at a constant speed, and after the additi...

Embodiment 3

[0044] Step 1), 260g cobalt chloride hexahydrate is dissolved in 279g concentration and is the tartaric acid solution of 50wt%, then drips the ammoniacal liquor that concentration is 18wt%, the pH value of solution is adjusted to 12, obtains cobalt complex metal salt solution and Placed in a three-necked bottle for use;

[0045] Step 2), with 100ml of silica carrier (average particle diameter is 85um after pre-calcining treatment, loose bulk ratio is 0.4g / ml, specific surface area is 300m 2 / g of silicon oxide particles) is poured into the complex metal salt solution under stirring, the ultrasonic instrument and water bath heating are turned on, and the temperature of the cobalt complex metal salt solution is maintained at 60°C;

[0046] Step 3), 174g concentration is that the hydrazine hydrate of 80wt% and equal volume (about 170ml) concentration is the ruthenium trichloride solution of 0.05mol / L isokinetic dropwise in the mixture solution, after the reduction reaction starts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com