A W-type ferrite electromagnetic-wave absorbent and the corresponding preparation method

An electromagnetic wave absorbing and ferrite technology, applied in chemical instruments and methods, electrical components, other chemical processes, etc., can solve the problems of time-consuming processes, limited mass production of materials, and complexity, and achieve thin coatings and easy processing. and mass production, the effect of wide bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Add Ba(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O was dissolved in distilled water and stirred to obtain a clear and transparent solution. The molar ratio of raw materials: Ba / Co / Fe=1:2:16.

[0029] Step 2: Add citric acid to the solution of step (1) and stir to obtain a clear and transparent solution. The molar ratio of raw materials: citric acid / Ba=19:1.

[0030] Step 3: Add ethylene glycol to the solution of step (2) and stir to obtain a uniform solution. The molar ratio of raw materials: ethylene glycol / citric acid = 1:1.

[0031] Step 4: Add ammonia to the solution prepared in step (3), mix it completely, and adjust the solution to neutral, pH=7.

[0032] Step 5: Place the solution of step (4) in a water bath at 90°C to evaporate slowly for 2 hours, and then dry it in an oven at 130°C until a black dry gel is formed.

[0033] Step 6: Pre-burn the dry gel at 450°C for 3 hours to completely decompose the organic matter.

[0034] Step 7: Put the pre-fi...

Embodiment 2

[0037] Step 1: Add Ba(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O was dissolved in distilled water and stirred to obtain a clear and transparent solution. Raw material molar ratio: Ba / Co / Fe=1:2:15.2.

[0038] Step 2 to Step 6: Same as Step 2 to Step 6 in Example 1.

[0039] Step 7: Put the pre-fired sample in a muffle furnace, heat up to 1800°C at a rate of 5°C / min, keep it for 5 hours, and cool down with the furnace to obtain a single W-type ferrite crystal phase.

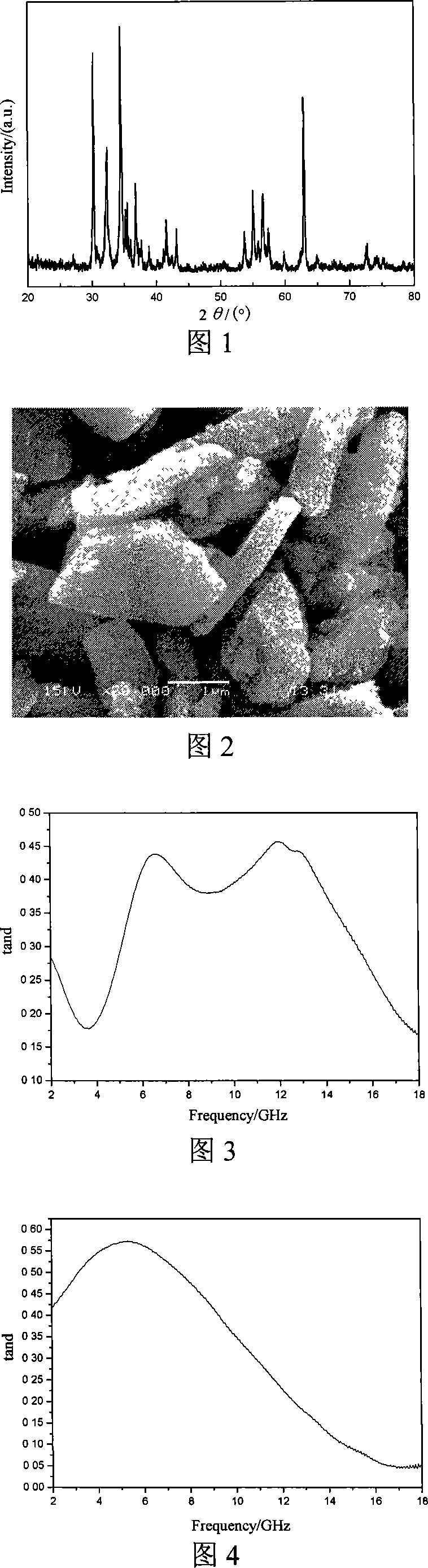

[0040] Figure 2 is a SEM photograph of the prepared ferrite. The prepared sample has a particle size of 1 to 5 microns and a uniform distribution.

Embodiment 3

[0042] Step 1: Add Ba(NO 3 ) 2 , Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 ·9H 2 O was dissolved in distilled water and stirred to obtain a clear and transparent solution. The molar ratio of raw materials: Ba / Co / Ni / Fe=1:1:1:16.

[0043] Step 2 to Step 6: Same as Step 2 to Step 6 in Example 1.

[0044] Step 7: Place the pre-fired sample in a muffle furnace, heat up to 1000°C at a rate of 5°C / min, keep it for 3 hours, and cool down with the furnace to obtain ferrite with a particle size of 1-10 microns. It is a single W shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com