Reduction-resistant nickel electrode ceramic dielectric material

A ceramic dielectric and nickel electrode technology, applied in the field of ceramic dielectric materials, can solve the problem of high production cost, and achieve the effects of improving compressive strength, high reliability and uniform grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

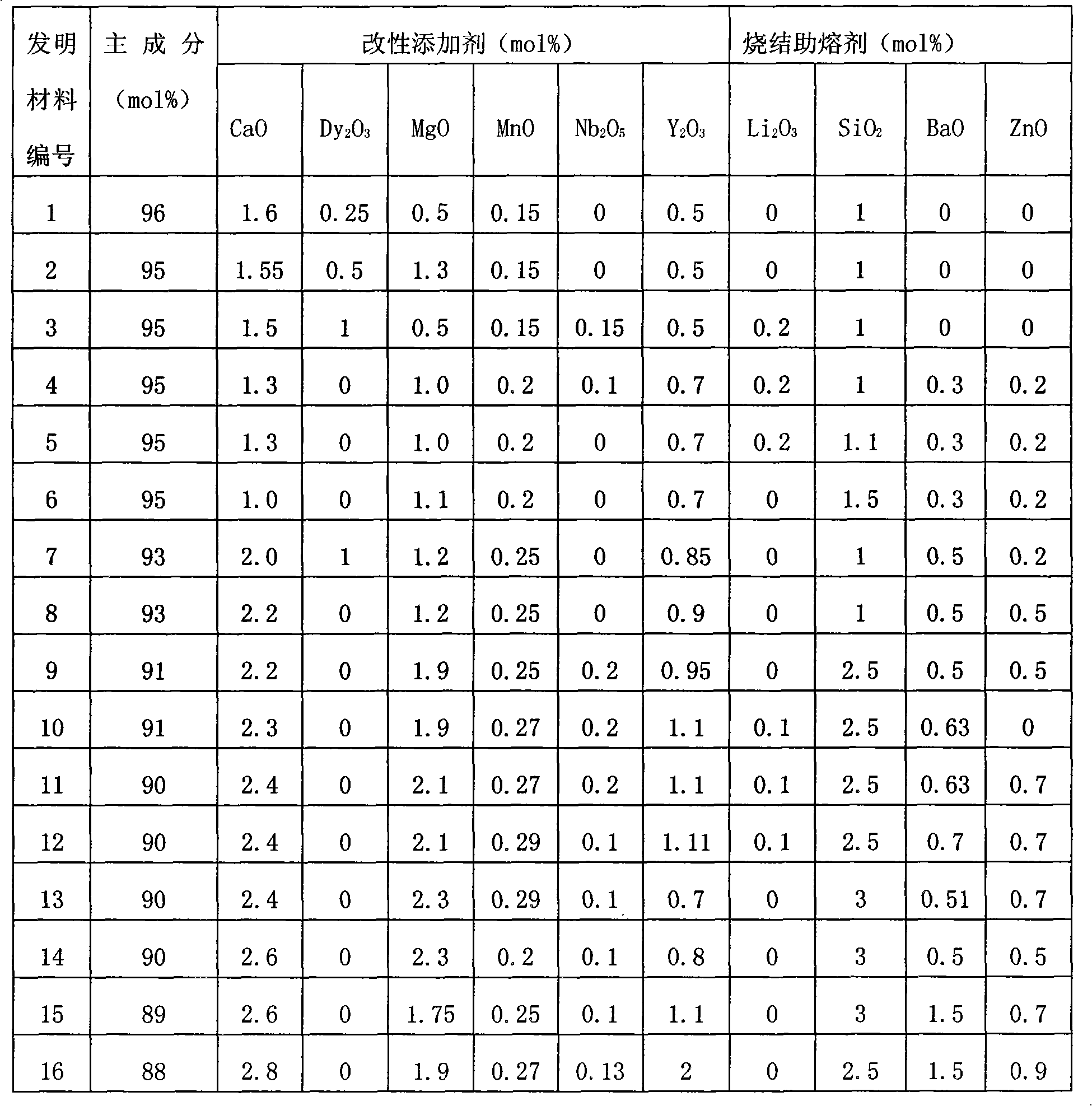

[0017] An anti-reduction nickel electrode ceramic dielectric material and a new MLCC manufacturing method thereof, in Table 1 No. 1 to No. 16 material formulations, BT can pass through BaO and TiO 2 Obtained by sintering synthesis, various small materials, namely glass components and modified additives) can be purchased directly, using the new technology of BT+ small materials, that is, MLCC direct batching method (mixing BT, glass components and modified additives to make casting slurry The material is cast, and the MLCC is cast to 20um. When these anti-reduction nickel electrode ceramic dielectric materials are used to make MLCC products by conventional methods, the sintering temperature is 1270 ° C ~ 1290 ° C, and the 0603B103K specification products are made. After making MLCCs, At room temperature of 25°C, use HP4278 to test capacitor capacity and loss at 1MHz, 1.0V (AC); use SF2512 fast insulation machine, apply 100V DC rated voltage for 10 seconds, and test insulation re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com