Method for comprehensively utilizing vanadium and titanium resources of vanadium titano-magnetite

A vanadium-titanium magnetite, vanadium-titanium technology, applied in metallurgy and chemical industry, can solve the problems of polluted environment, low recovery rate, heavy pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

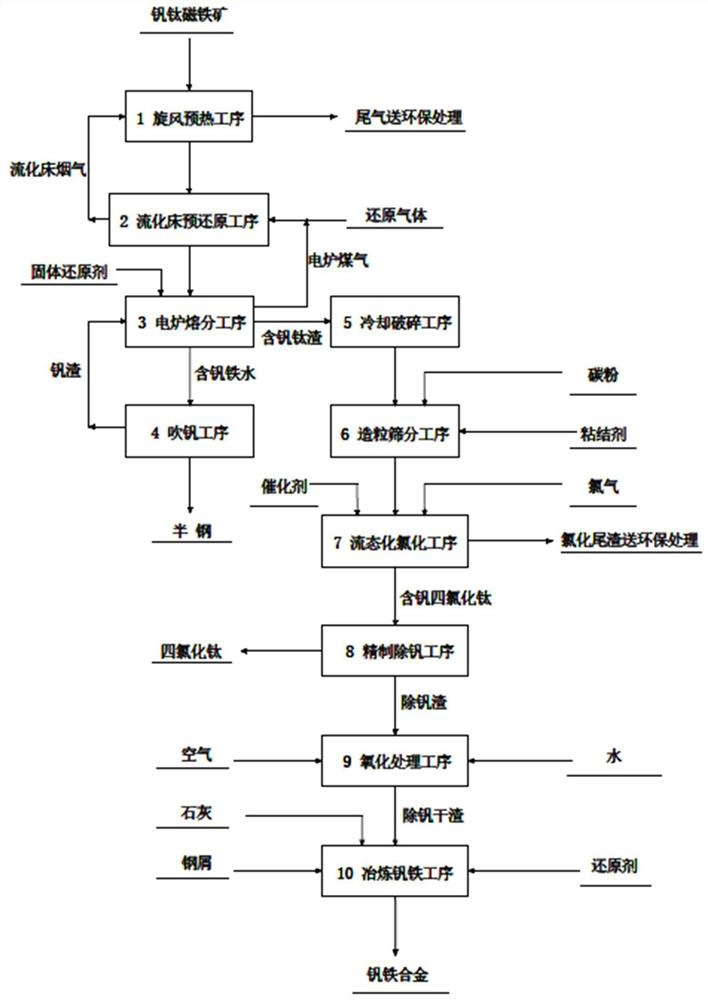

[0045] combine figure 1 , a method for comprehensive utilization of vanadium-titanium-magnetite vanadium-titanium resources used in this embodiment, comprising cyclone preheating process 1, fluidized bed pre-reduction process 2, electric furnace melting process 3, vanadium blowing process 4, cooling and crushing Process 5, granulation and screening process 6, fluidized chlorination process 7, refining vanadium removal process 8, oxidation treatment process 9 and ferrovanadium smelting process 10, the method is carried out according to the following steps:

[0046] 1) The vanadium-titanium magnetite is sent to the cyclone preheating process 1 to exchange heat with the high-temperature fluidized bed flue gas from the fluidized bed pre-reduction process 2, and the vanadium-titanium magnetite after heat exchange is sent to the fluidized bed pre-reduction process 2. The tail gas from the cyclone preheating process is sent to environmental protection treatment;

[0047] 2) In the f...

Embodiment 2

[0056] This embodiment adopts the method for the comprehensive utilization of vanadium-titanium-magnetite vanadium-titanium resources described in Example 1. In the fluidized bed pre-reduction process 2, the operating temperature is 600 ° C, the reducing gas is blast furnace gas, and the metallization rate is 10%. . The solid reducing agent in the electric furnace melting process 3 is coal powder, the operating temperature is 1400° C., the amount of solid reducing agent added is 10% of the mass of vanadium titanomagnetite, and the vanadium concentration in titanium slag is 1% of the vanadium concentration in molten iron. times. The vanadium slag obtained in the vanadium blowing step 4 is returned to the electric furnace melting step 3 again. In the cooling and crushing step 5, the average particle size of the vanadium-containing titanium slag after crushing is 0.1 μm. In the granulation and screening step 6, activated carbon with an average particle size of 0.1 μm is used as...

Embodiment 3

[0058] This embodiment adopts the method for comprehensive utilization of vanadium-titanium magnetite vanadium-titanium resources described in Example 1. In the fluidized bed pre-reduction process 2, the operating temperature is 960 ° C, the reducing gas is methane reformed gas, and the metallization rate 60%. The solid reducing agent in the electric furnace melting process 3 is petroleum coke, the operating temperature is 1800° C., the amount of solid reducing agent added is 40% of the mass of vanadium titanomagnetite, and the vanadium concentration in titanium slag is 5% of the vanadium concentration in molten iron. times. The vanadium slag obtained in the vanadium blowing step 4 is returned to the electric furnace melting step 3 again. In the cooling and crushing step 5, the crushed vanadium-containing titanium slag has an average particle size of 50 μm. In the granulation and screening step 6, coal powder with an average particle size of 50 μm is used as the carbon powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com