Ozone microbubble air floating concentration device and sludge conditioning and concentration method

A concentration device and micro-bubble technology, applied in dehydration/drying/concentration sludge treatment, oxidation treatment sludge, sludge treatment, etc., can solve the problem of low dryness of sludge concentration and unreasonable sludge conditioning methods, etc. problem, achieve the effect of improving dehydration performance and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

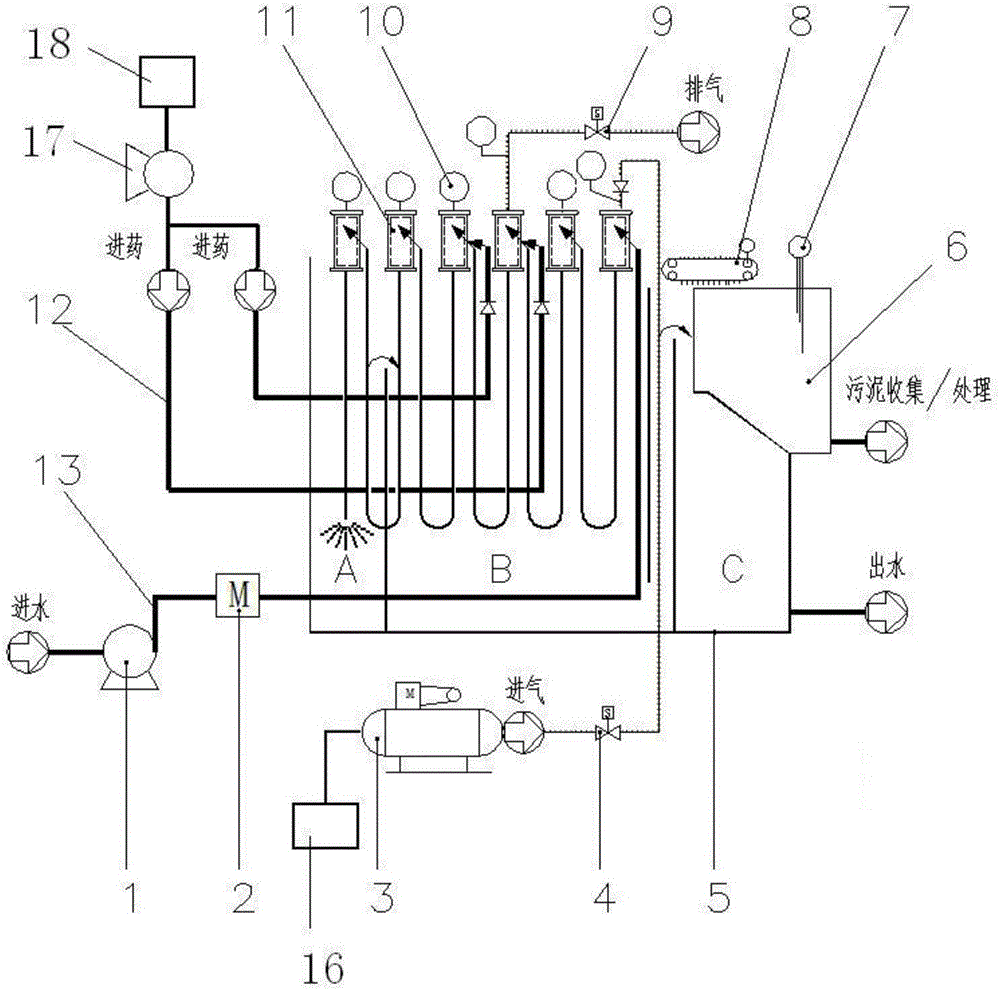

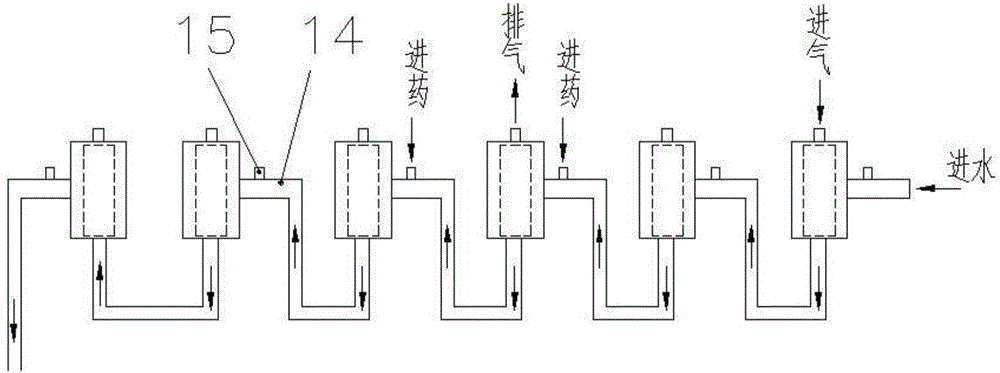

[0033] Such as figure 1 , image 3 Shown, a kind of ozone microbubble air flotation concentration device of the present invention, it comprises a reaction tank 5, above the reaction tank, six groups (six stages) of vortex three-phase mixer 11 (from water outlet side to water inlet side) are arranged side by side in series Arranged in sequence as the first stage, the second stage...the sixth stage), each stage of the vortex three-phase mixer is equipped with a first-stage reactor; the reaction tank is divided into three chambers from the water inlet side to the water outlet side by the weir plate, namely : contact chamber A, separation chamber B and clean water collection chamber C; a slag remover 8 is arranged above the separation chamber B, and the other end of the slag remover 8 extends horizontally above the slag collection tank 6; the top of the slag collection tank 6 is lower than the vortex three-phase The bottom of the mixer 11; more than half of the lower part of the ...

Embodiment 2-5

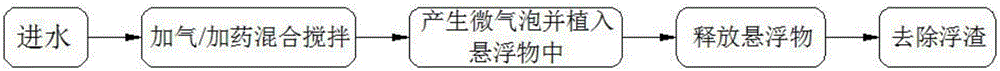

[0050] A kind of method that utilizes the ozone microbubble air flotation concentration device described in embodiment 1 of the present invention to carry out sludge conditioning and concentration is as follows: (embodiments 2-5 are all processed according to this method)

[0051] Sludge (domestic sewage sludge, industrial wastewater sludge, water supply sludge) is transported into a multi-stage vortex three-phase mixer through a water inlet pipe to form a vortex using a pressurized water inlet pump, that is, from the first stage vortex three-phase mixer Enter the following several stages of vortex three-phase mixer one by one; after the ozone is prepared by the ozone generator, it is compressed by a gas booster pump or an air compressor to increase the pressure of the ozone gas, and then it is transported into the first stage of the vortex three-phase mixer through the intake pipe. In the phase mixer; after the PAM medicine is prepared by the medicine preparation device, use t...

Embodiment 2

[0054] Embodiment 2: the processing object is the remaining sludge (water content 99%) discharged from the secondary sedimentation tank of a sewage treatment plant based on a certain domestic sewage water source, and the ozone microbubble air flotation concentration device of embodiment 1 is adopted to carry out conditioning, Concentration treatment: PAM dosage is 0.003gPAM / gDS (dry sludge), ozone dosage is 0.00625gO 3 / gDS (dried sludge); the pressure of the water inlet pump is about 0.8Mpa; the pressure of ozone gas (that is, the pressure at the outlet of the gas booster pump or air compressor) is slightly greater than the pressure of the water inlet pump (slightly greater than 0.8MPa); PAM agent dosing The feeding pressure of the pump is slightly higher than the inlet pump pressure (slightly higher than 0.8MPa). The pressure of the first-stage vortex three-phase mixer is the highest (about 0.8Mpa), and the pressure in the subsequent vortex three-phase mixer decreases gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com