Electro-chemical machining technology of inner hole wall turbulence structure of metal parts

A technology of electrochemical processing and metal parts, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to process small-sized apertures, difficulties in making electrodes, and difficulty in realization, achieving small investment and shielding The influence of electric field and the effect of reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

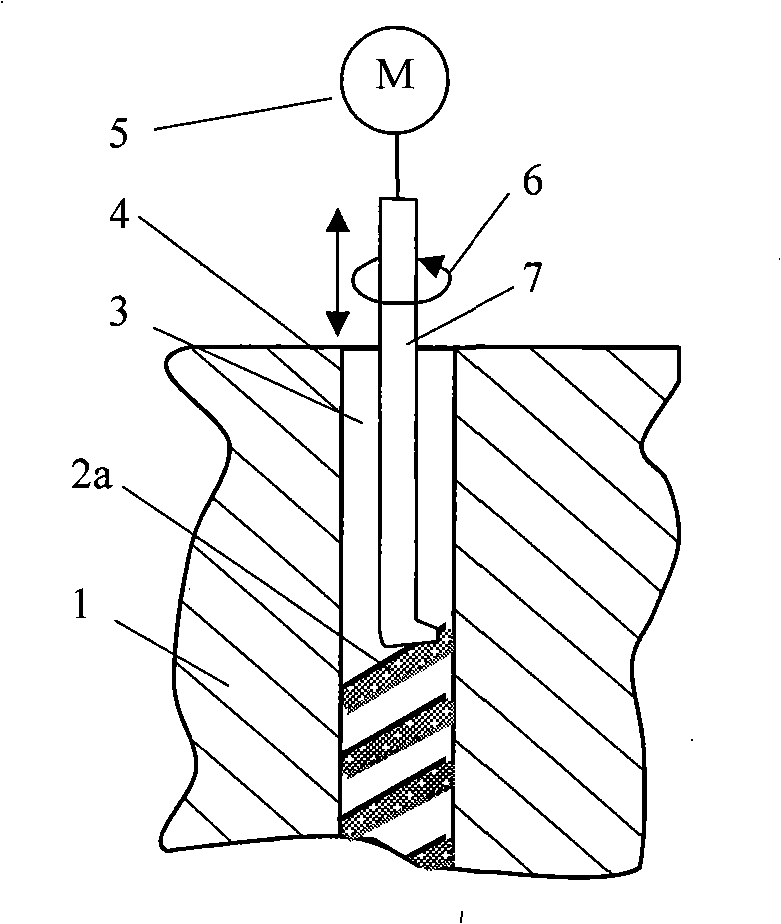

[0041] Embodiment 1 (groove shape turbulent flow structure):

[0042] A smooth circular hole 3 with an aperture of 3 mm is processed in advance on the metal part 1 by the electric discharge method. Next, if figure 1 As shown, the gluing spray head 7 is clamped on the machine tool spindle and penetrates into the smooth circular hole 3. The gluing spray head 7 can realize different forms of motion (such as circumferential and radial feed 6) driven by the machine tool motor 4. , The speed of the glue sprayed by the glue nozzle is controlled by an external pressure pump. The insulating glue 2 is made of 352AUV epoxy resin glue, and the curing agent is triethylenetetramine. For every 100 parts of resin, 10 parts of curing agent are used: 3 at 100°C hours to cure.

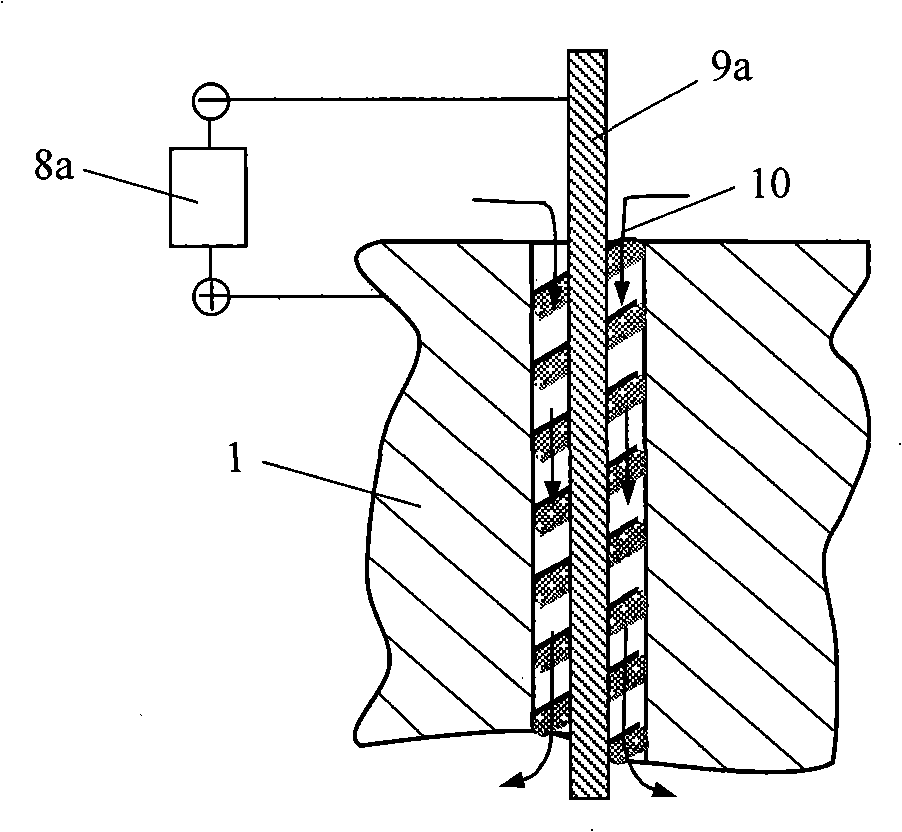

[0043] After the insulating glue 2 is cured, the metal part 1 is installed on the electrolytic processing machine tool, the workpiece is connected to the positive electrode of the electrolytic processing power supply ...

Embodiment 2

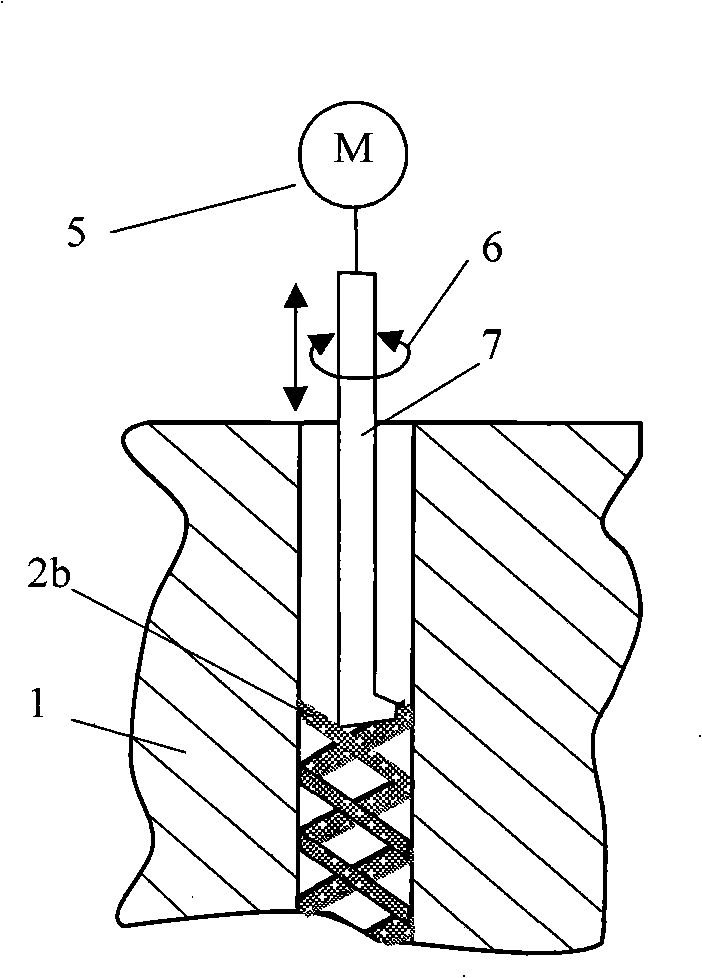

[0045] Embodiment 2 (boss-shaped turbulent flow structure):

[0046] A smooth round hole 3 with a diameter of 2 mm is pre-machined on the metal part 1 by electric discharge machining, and then a layer of insulating glue 2 is applied on the inner wall of the smooth round hole 3 by the same glue coating method as in Example 1. After the insulating glue 2 is cured, coat the outer surface 12 of the metal part with a layer of insulating glue and put it into the electrolyte tank filled with electroforming liquid, and the metal wire 13 for electroforming passes through the central axis of the smooth circular hole on the metal part 1 , the moving speed of the wire 13 for electroforming is controlled by the pay-off wheel and the take-up wheel, as the wire 13 for electroforming moves axially in the hole, the electroforming liquid is brought into the smooth circular hole 3, and a suitable The type of electrolyte is compatible with the metal to be deposited. When the workpiece is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com