A kind of yttrium-cerium composite oxide-based up-conversion luminescent material and preparation method thereof

A composite oxide, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminous efficiency, luminous intensity can not meet practical application requirements, etc., achieve high luminous intensity, small powder particles, Single phase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

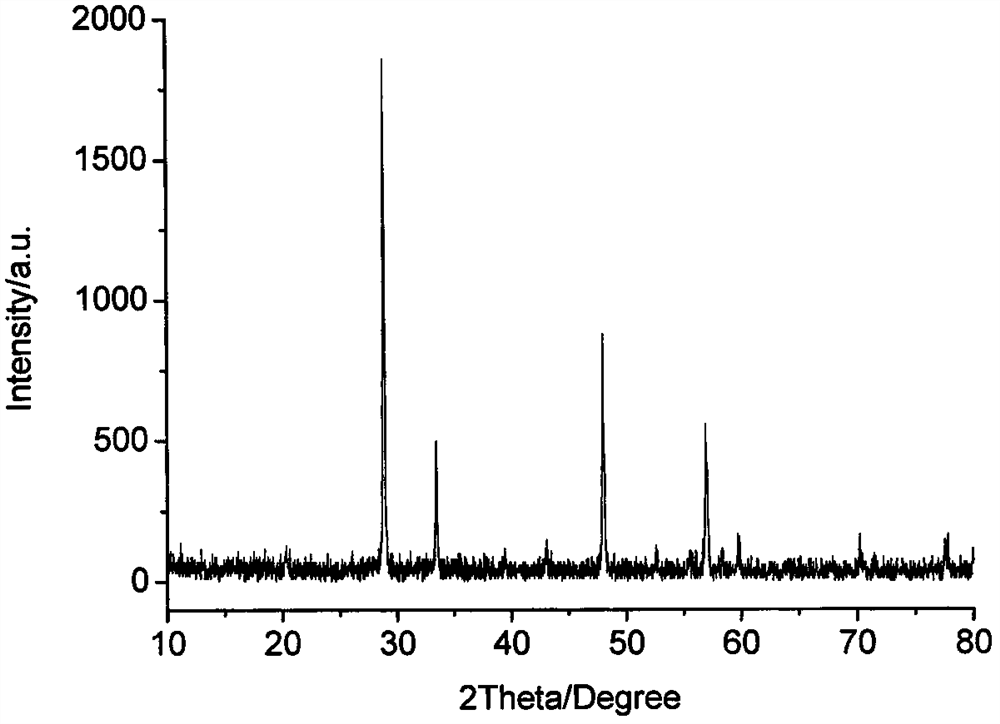

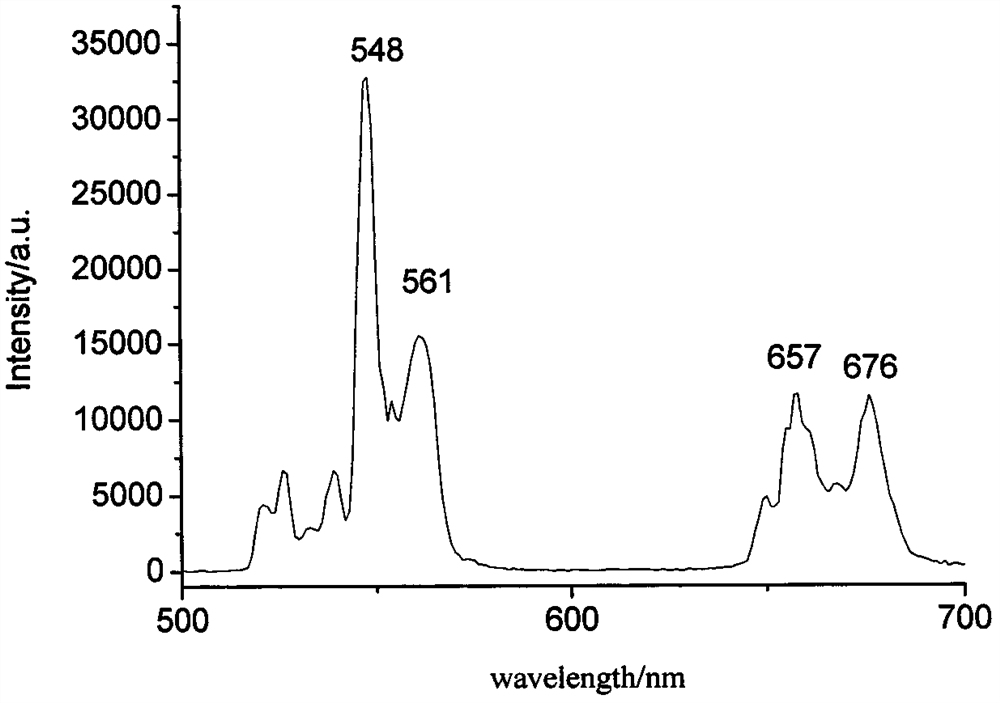

[0018] Preparation of Er by sol-gel method 3+ , Yb 3+ Double-doped yttrium-cerium composite oxide-based up-conversion luminescent material Y 1.97 Er 0.01 Yb 0.02 CeO 5 , the specific operation is as follows:

[0019] The ratio of various raw materials is calculated according to the mole fraction of each metal element in the material composition. Weigh 3.2713g Ce(NO 3 ) 3 ·6H 2 O, 5.6865g Y (NO 3 ) 3 ·6H 2 O, 0.0334g Er(NO 3 ) 3 ·5H 2 O, 0.0698g Yb(NO 3 )·6H 2 O put into a beaker, add 70mL of distilled water, stir to make it fully dissolved to form a uniform mixed solution, add 8.692g of citric acid into the mixed solution and stir evenly, slowly add 2mol / L of citric acid into the mixed solution at a certain speed under stirring conditions Ammonia water until the pH value of the solution is 4-5 to make a transparent sol. Put the beaker containing the sol in a constant temperature water bath for gelation reaction. The gelation temperature is 60°C and the time is ...

Embodiment 2

[0022] Preparation of Er by sol-gel method 3+ , Yb 3+ Double-doped yttrium-cerium composite oxide-based up-conversion luminescent material Y 1.81 Er 0.01 Yb 0.18CeO 5 ,details as follows:

[0023] Weigh 3.2713g Ce(NO 3 ) 3 ·6H 2 O, 5.2246g Y (NO 3 ) 3 ·6H 2 O, 0.0334gEr(NO 3 ) 3 ·5H 2 O, 0.6282g Yb(NO 3 )·6H 2 O is put into beaker, all the other steps are with embodiment 1.

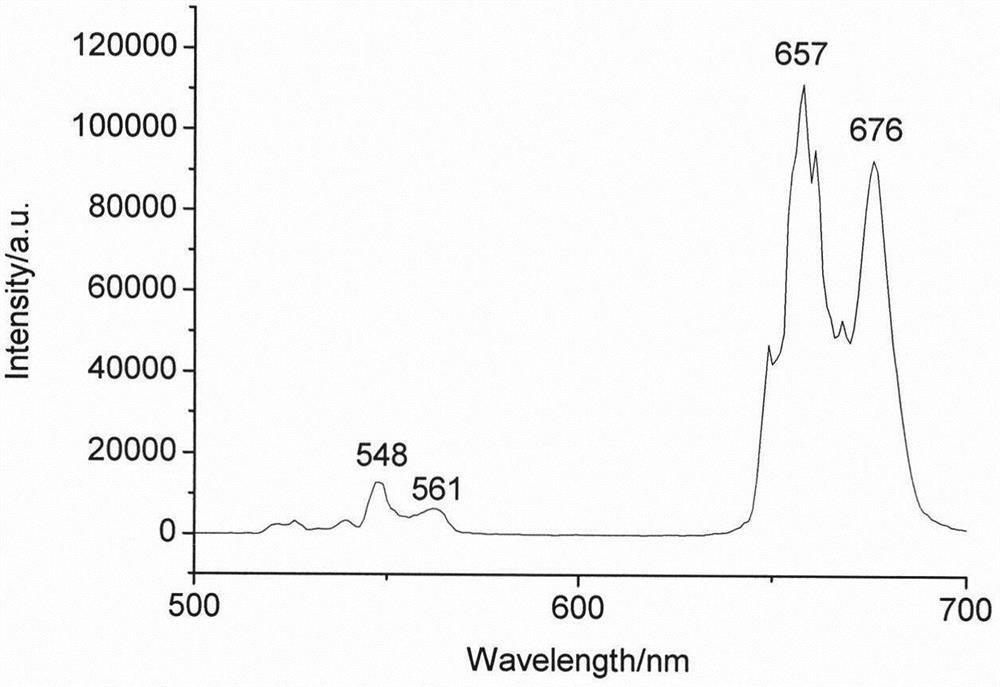

[0024] image 3 for Er 3+ , Yb 3+ Double-doped yttrium-cerium composite oxide-based up-conversion luminescent material Y 1.81 Er 0.01 Yb 0.18 CeO 5 The up-converted fluorescence spectrum of . At room temperature, the powdery sample emits bright red light when irradiated by a 30mw 980nm semiconductor laser.

Embodiment 3

[0026] Preparation of Ho by sol-gel method 3+ , Yb 3+ Double-doped yttrium-cerium composite oxide-based up-conversion luminescent material Y 1.945 Ho 0.005 Yb 0.05 CeO 5 , the specific operation is as follows:

[0027] The ratio of various raw materials is calculated according to the mole fraction of each metal element in the material composition. Weigh 3.4382g Ce(NO 3 ) 3 ·6H 2 O, 6.0661g Y (NO 3 ) 3 ·6H 2 O, 0.0175g Ho(NO 3 ) 3 ·5H 2 O, 0.1479g Yb(NO 3 ) 3 ·6H 2 O put into a beaker, add 70mL of distilled water, stir to fully dissolve to form a uniform mixed solution, add 8.692g of citric acid to the mixed solution and stir evenly, slowly add 2mol / L to the mixed solution at a certain speed under stirring conditions ammonia water until the pH value of the solution is 4 to 5 to make a transparent sol, put the beaker containing the sol in a constant temperature water bath for gelation reaction, the gelation temperature is 60°C, and the time is 5 to 8h. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com