Method for preparing MgAlON transparent ceramic in pressureless sintering way

A technology of transparent ceramics and absolute ethanol, which is applied in the field of preparation of MgAlON transparent ceramics, can solve the problems of limiting the shape and size of sintered products, having no optical properties of materials, and difficult control of components, so as to achieve lower sintering temperature, uniform particle size, The effect of rapid reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The pressureless sintering preparation method of MgAlON transparent ceramics, it comprises the steps:

[0046] 1) Preparation of MgAlON transparent ceramic powder:

[0047] ①Weigh 88.21g of α-alumina powder, 3.79g of aluminum nitride powder and 8g of magnesium oxide powder, put them into a mixing bottle and mix to obtain mixed powder A; 1 Add alumina balls, add 200mL of absolute ethanol, and roller mill for 24 hours to obtain slurry A;

[0048] ②Dry the slurry A (dry in vacuum at 50°C) to obtain the mixture A;

[0049] ③ Pass the dried mixture A through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. 0.05Mpa nitrogen was introduced into the synthesis device as a protective gas; a large current was directly applied to the graphite reactor, heated to 1700°C at a heating rate of 100°C, kep...

Embodiment 2

[0063] The pressureless sintering preparation method of MgAlON transparent ceramics, it comprises the steps:

[0064] 1) Preparation of MgAlON transparent ceramic powder:

[0065] ① Weigh 88.77g of α-alumina powder, 7.23g of aluminum nitride powder and 4g of magnesium oxide powder, put them into a mixing bottle and mix to obtain mixed powder A; 1 Add alumina balls, add 200mL of absolute ethanol, and roller mill for 24 hours to obtain slurry A;

[0066] ②Dry the slurry A (dry in vacuum at 50°C) to obtain the mixture A;

[0067] ③Put the dried mixture A through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. 0.03Mpa nitrogen was introduced into the synthesis device as a protective gas; a large current was directly applied to the graphite reactor, heated to 1700°C at a heating rate of 200°C, kept...

Embodiment 3

[0081] The pressureless sintering preparation method of MgAlON transparent ceramics, it comprises the steps:

[0082] 1) Preparation of MgAlON transparent ceramic powder:

[0083] ① Measure 84.36g of α-alumina powder, 7.64g of aluminum nitride powder and 8g of magnesium oxide powder, put them into a mixing bottle and mix to obtain mixed powder A; 1 Add alumina balls, add 250mL of absolute ethanol, and roller mill for 24 hours to obtain slurry A;

[0084] ②Dry the slurry A (dry in vacuum at 50°C) to obtain the mixture A;

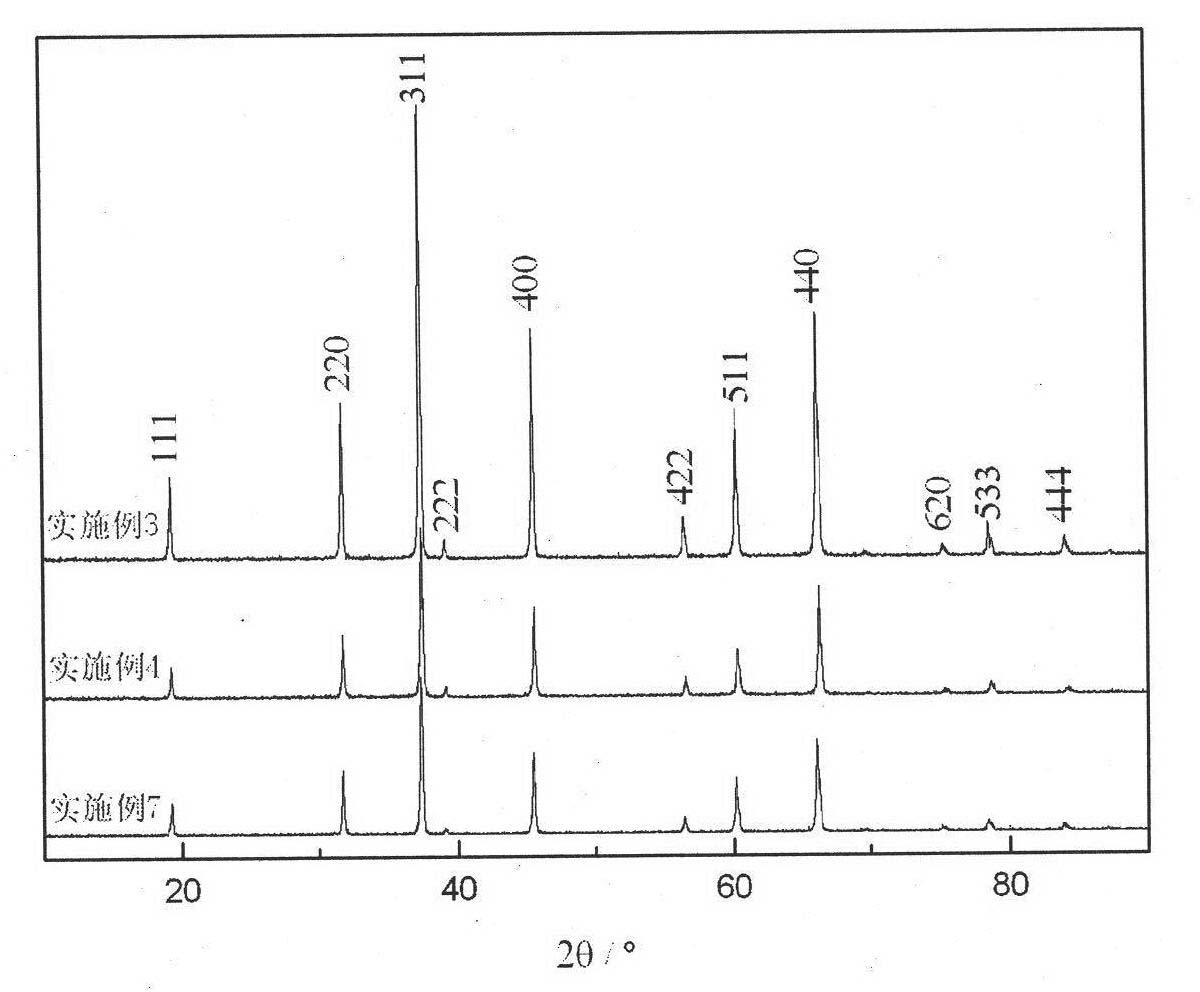

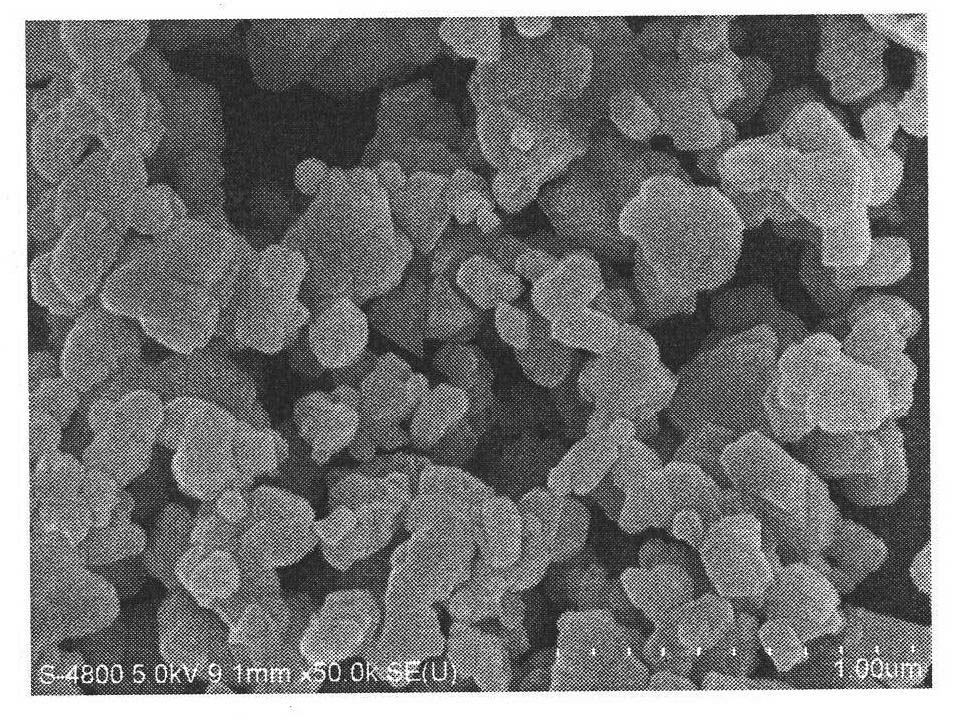

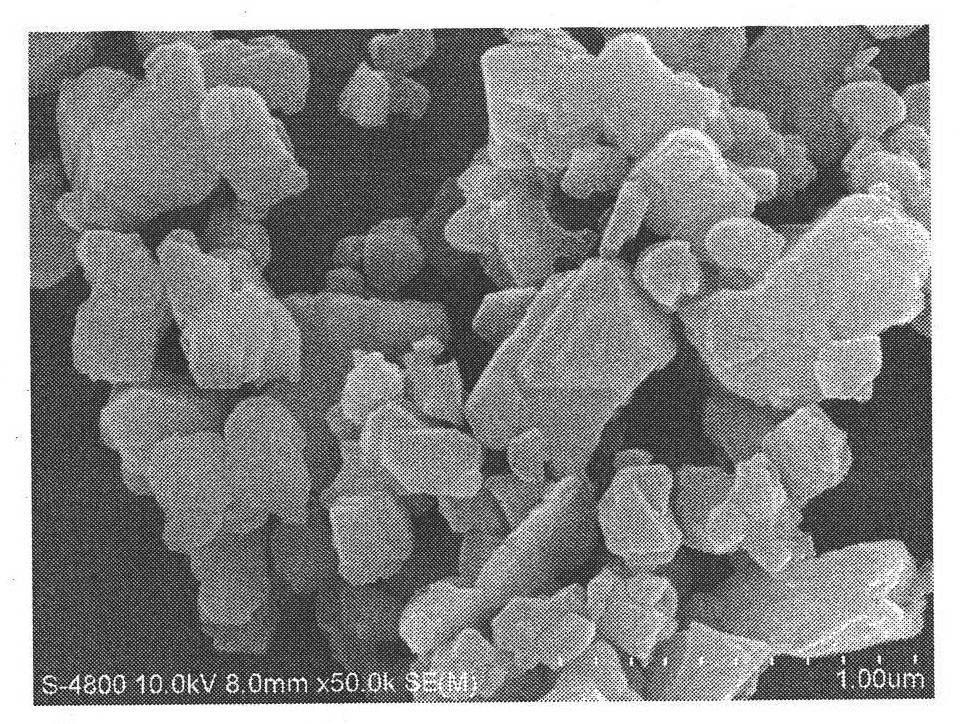

[0085] ③ Pass the dried mixture A through a 100-mesh sieve, take 3g and put it into a graphite crucible coated with boron nitride on the inner wall. The crucible is placed in a graphite reactor, and the graphite reactor is placed in a high-current reaction synthesis device. 0.05Mpa nitrogen was introduced into the synthesis device as a protective gas; a large current was directly applied to the graphite reactor, heated to 1650°C at a heating rate of 300°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com