Method for preparing graphene by reducing graphene oxide by utilizing reducing agent

A graphene and reducing agent technology, applied in graphene, nano-carbon and other directions, can solve the problems of long reaction time, complex process, high toxicity, etc., and achieve the effects of reducing preparation cost, rapid reaction process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

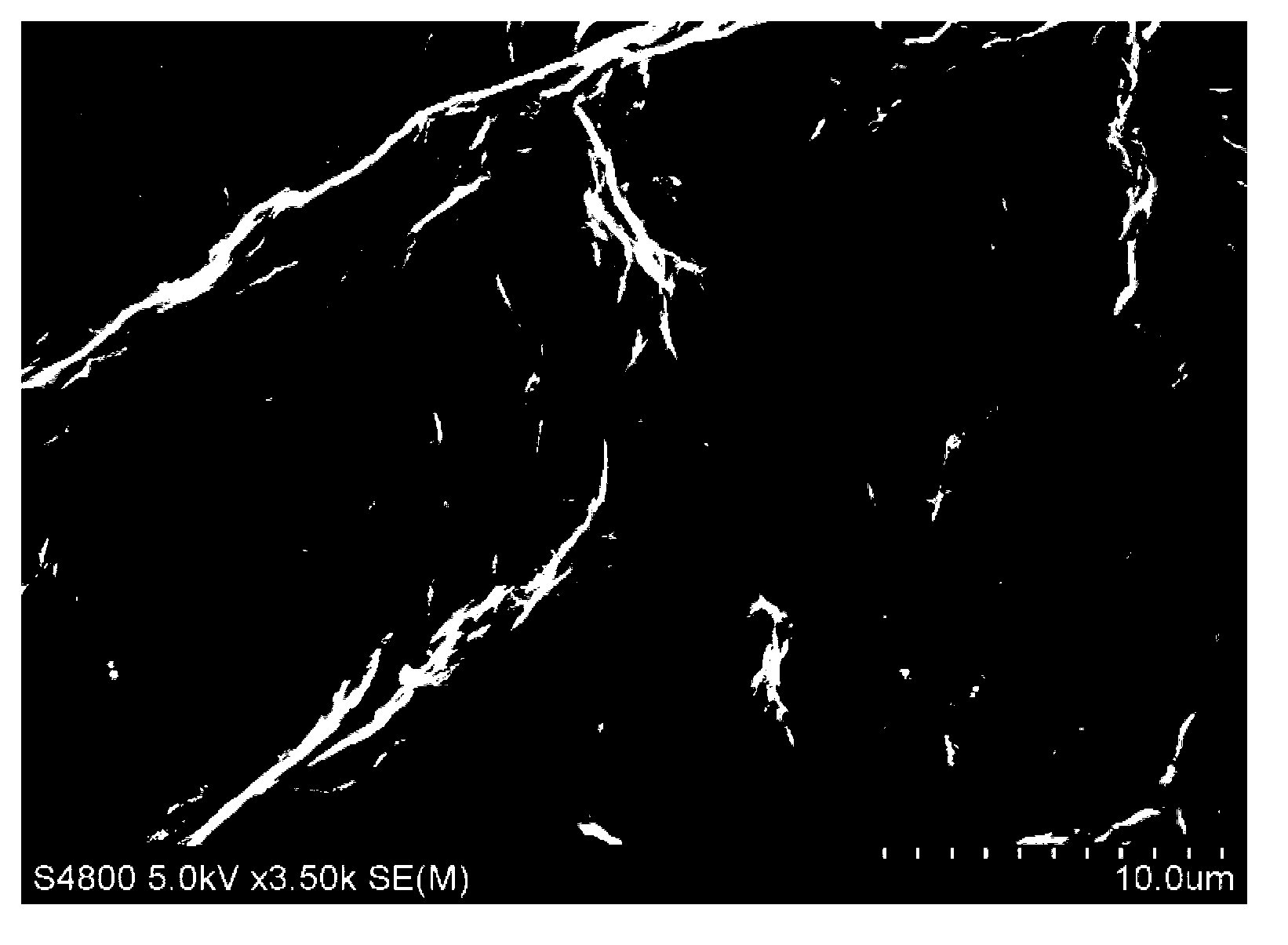

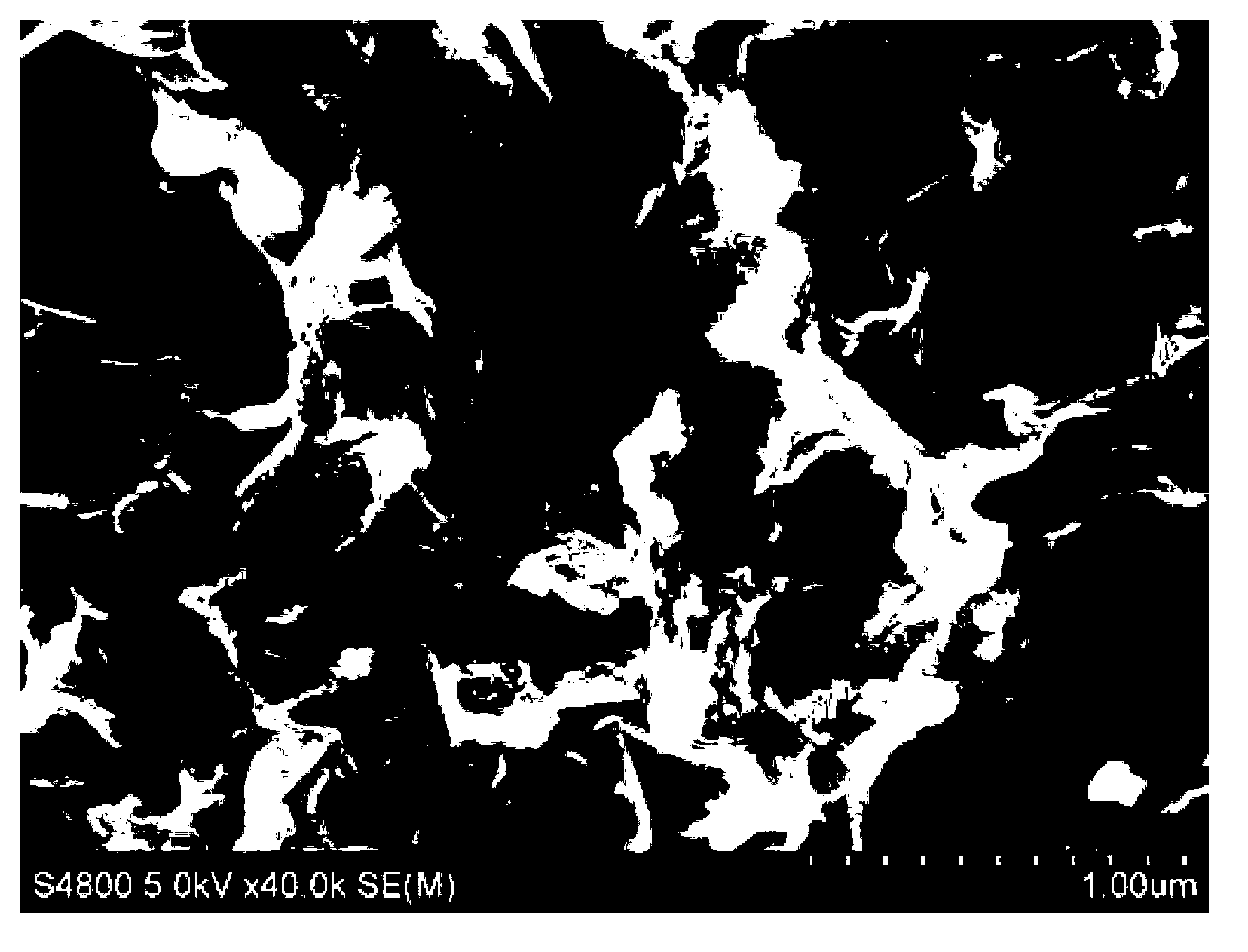

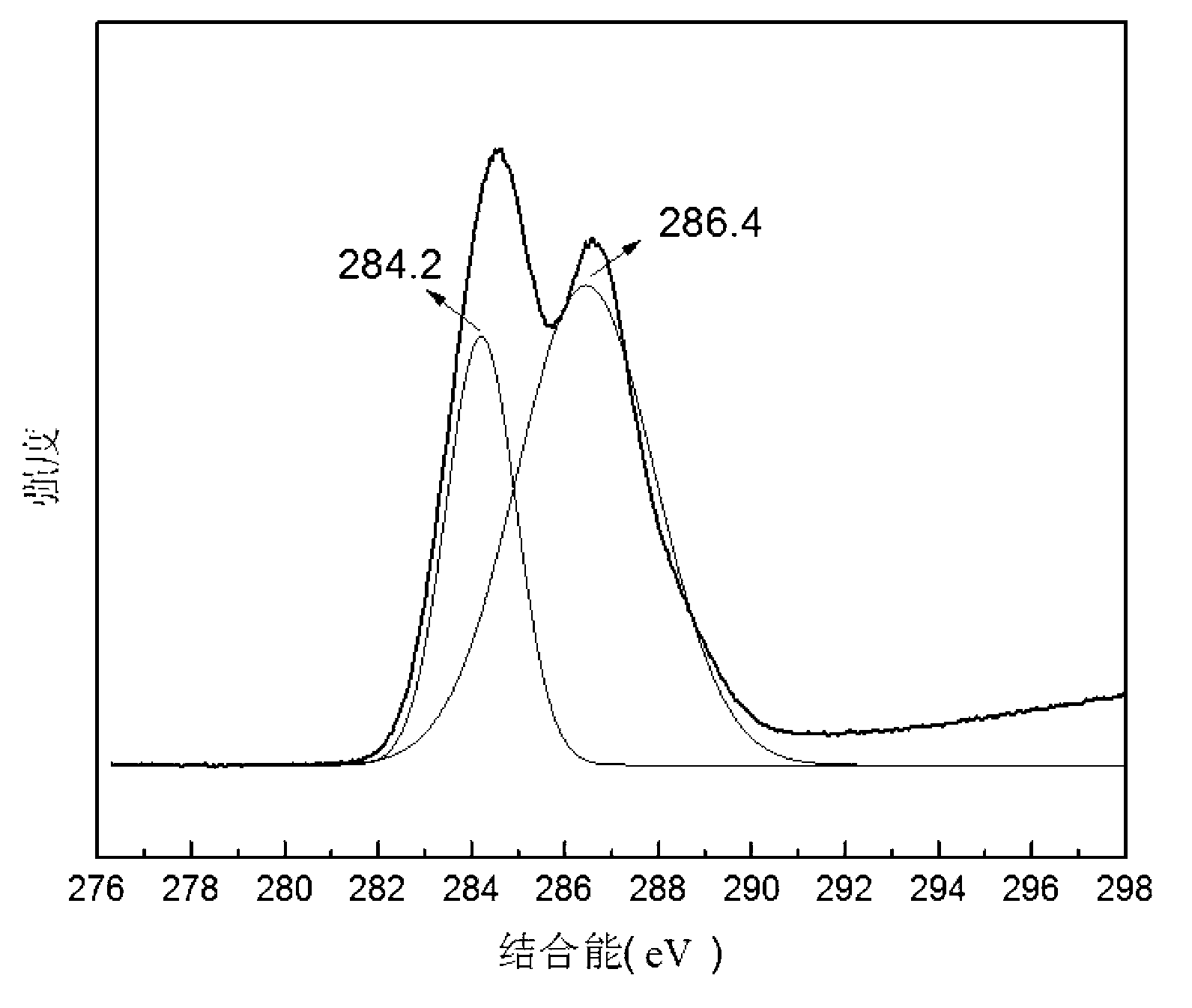

[0007] Specific embodiment 1: This embodiment is a method for preparing graphene by reducing graphene oxide with a reducing agent, which is specifically completed according to the following steps: 1. Ultrasonic dispersion: adding deionized water to graphene oxide at a frequency of 80KHz~100KHz ultrasonic wave assisted by ultrasonic dispersion for 20min~40min, then a uniform graphene oxide aqueous dispersion solution with a concentration of 4mg / L~8mg / L will be obtained; 2. Reduction: uniform oxidation with a concentration of 4mg / L~8mg / L Add sodium tellurium hydride aqueous solution to the graphene aqueous dispersion solution, and stir for 1h~3h at room temperature and stirring speed of 200r / min~250r / min, and then separate by suction filtration. The solid obtained is washed with sodium borohydride aqueous solution for 2~8 After washing with deionized water for 1 to 5 times, and then separating by suction filtration, the washed solid is obtained, and then the washed solid is dried ...

specific Embodiment approach 2

[0011] Specific embodiment two: this embodiment is different from specific embodiment one in that: the graphene oxide described in step one is prepared according to the following steps: add 98% sulfuric acid and mass fraction to 500 mesh natural flake graphite Phosphoric acid with a fraction of 83%~98%, add potassium permanganate, react at room temperature for 1.5h~2.5h, then react in a water bath at a temperature of 35℃ for 20h~28h, then add deionized water and mass fraction It is 27.5%~35% hydrogen peroxide, and then centrifuged at a centrifugal speed of 3000r / min~5000r / min. The lower solid obtained is first washed with 3% hydrochloric acid once, and then washed with deionized water by repeated centrifugation. The obtained supernatant is neutral, and graphene oxide is obtained after washing; the volume ratio of the mass of the 500 mesh natural flake graphite to 98% sulfuric acid is (0.02g~0.03g): 1mL; The volume ratio of the mass of 500 mesh natural flake graphite to the phos...

specific Embodiment approach 3

[0012] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the sodium tellurium hydride aqueous solution described in step two is prepared according to the following steps: adding tellurium powder and sodium borohydride into deionized water, Then in an ice-salt bath and a stirring speed of 150r / min~250r / min, the reaction was stirred for 8h~12h to obtain the sodium tellurium hydride aqueous solution; the mass ratio of the tellurium powder to the sodium borohydride was (1.5~1.6): 1; The mass ratio of the deionized water to sodium borohydride is (18.5-19):1. Others are the same as the first or second embodiment.

[0013] The following tests are used to verify the effect of the present invention:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com