Method for reducing graphene oxide by using extracellular polymer

An extracellular polymer, graphene technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of high power consumption, corrosiveness, and high equipment requirements, achieve a high degree of reduction, easy to achieve, The effect of simple reduction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using the improved Hummer method to synthesize graphite oxide with flake graphite as raw material, weigh a certain quality of graphite oxide, disperse it in deionized water with a high-shear dispersing mixer, and use an ultrasonic cell crusher to peel off the graphite oxide, and finally After centrifugation at 4000r / min, the obtained supernatant is graphene oxide suspension with a concentration of about 600mg / L.

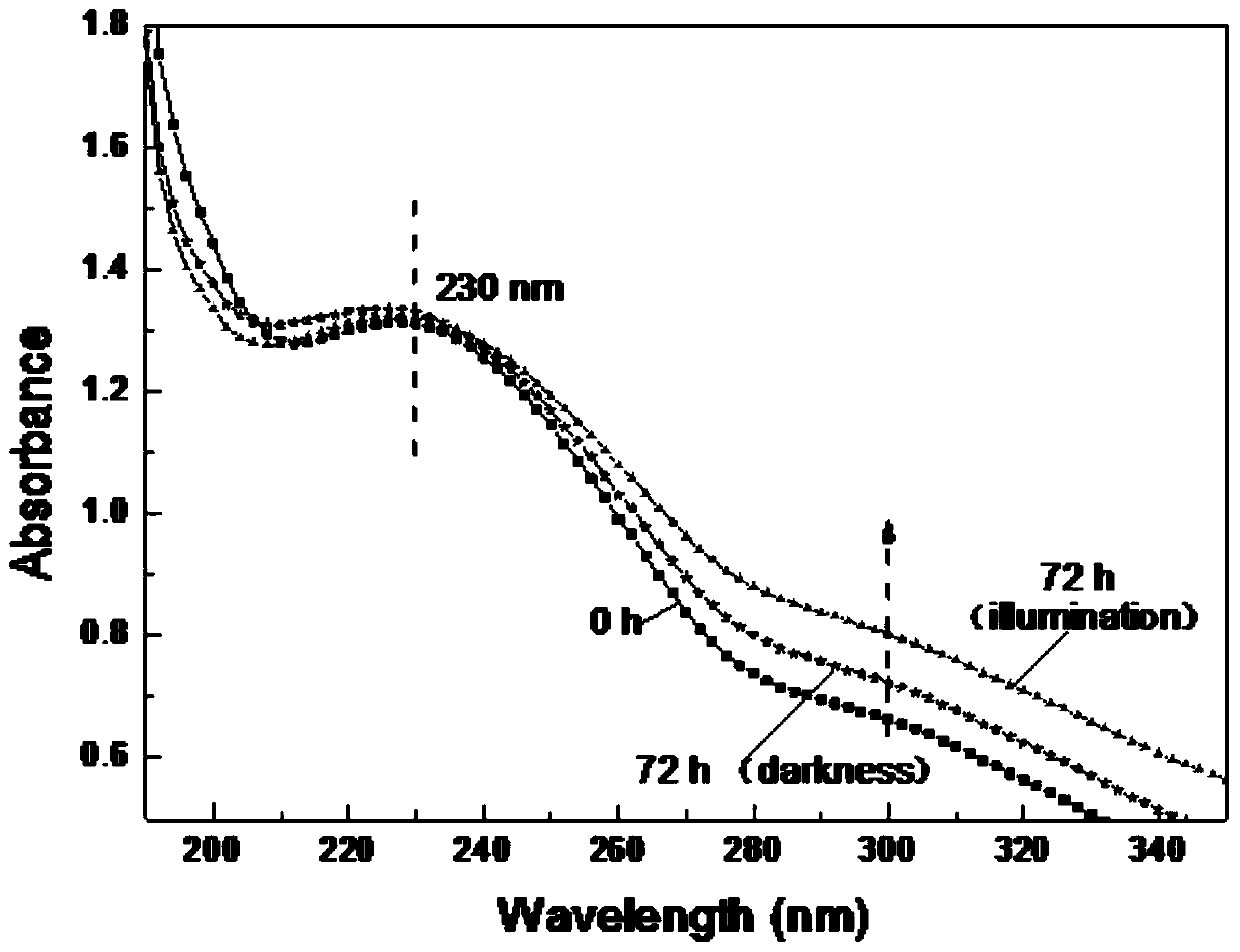

[0026] Two sets of graphene oxide suspensions were prepared, and the prepared EPS purified samples were added thereto according to the mass ratio of extracellular polymer: graphene oxide = 1:3, and the pH value of the solution was adjusted to 5.0 with HCl and NaOH. The mixture was sealed and placed in an environment of 25°C, and stirred and reacted under 3600LX light intensity and shading conditions respectively. After 72 hours, it was filtered, and the obtained solid was washed several times with deionized water and then freeze-dried to obtain reduced graphen...

Embodiment 2

[0029] Using the improved Hummer method to synthesize graphite oxide with flake graphite as raw material, weigh a certain quality of graphite oxide, disperse it in deionized water with a high-shear dispersing mixer, and use an ultrasonic cell crusher to peel off the graphite oxide, and finally Centrifuge at 4000r / min, and the obtained supernatant is graphene oxide suspension with a concentration of 300mg / L.

[0030] According to the mass ratio of extracellular polymer:graphene oxide=1:3, the prepared EPS purification sample was added to the graphene oxide suspension, and the pH value of the solution was adjusted to 5.0 with HCl and NaOH. The mixture was sealed and placed in an environment of 25°C, and stirred and reacted under the light intensity of 3600LX. Take samples at 0h, 4h, 8h, 12h, 24h, 48h, and 72h and put them into sealed vials for observation. The results are as follows: figure 2 shown. figure 2 It is shown that the color of the reaction solution deepens with th...

Embodiment 3

[0032] Using the improved Hummer method to synthesize graphite oxide with flake graphite as raw material, weigh a certain quality of graphite oxide, disperse it in deionized water with a high-shear dispersing mixer, and use an ultrasonic cell crusher to peel off the graphite oxide, and finally Centrifuge at 4000r / min, and the obtained supernatant is graphene oxide suspension with a concentration of 300mg / L.

[0033]According to the mass ratio of extracellular polymer: graphene oxide=1:1.5, 1:3, 1:6, 1:12, add the prepared EPS purified sample into the graphene oxide suspension respectively (wherein the blank group does not add EPS), adjust the pH value of the solution to 5.0 with HCl, NaOH. The mixture was sealed and placed in an environment of 25°C, and stirred and reacted under the light intensity of 3600LX. After 72 hours, the samples were put into a sealed vial for observation, and the results were as follows: image 3 shown. image 3 It was shown that different concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com