Preparation method for iron-dextrin

A technology for iron dextran and dextran, which is applied in the field of fine chemicals, can solve the problems of difficult control of the hydrolysis process of macromolecular dextran, complicated synthesis and purification processes of iron dextran, environmental pollution and the like, achieves controllable hydrolysis process, improved complexation stability, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

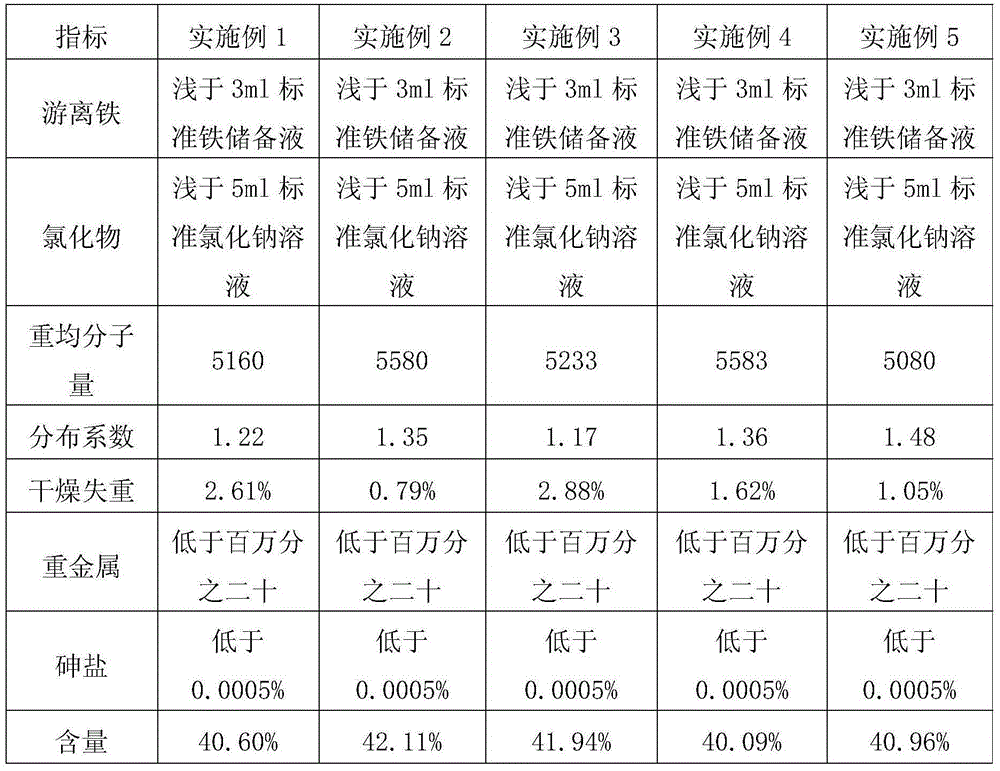

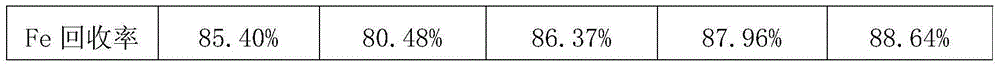

[0024] Obtaining low molecular weight dextran: Weigh 300g of macromolecular dextran (weight average molecular weight 33208, distribution coefficient 1.56), add 1L of distilled water, heat up to 55°C, stir until dissolved; add Chaetomium according to 30U / g substrate ratio α-1,6-dextranase from genus origin, start timing. After the reaction was carried out for 20 minutes, the temperature began to rise, and the temperature was kept at 100° C. for 10 minutes to inactivate the enzyme activity and terminate the reaction. According to the detection method for the molecular weight of dextran in the 2010 edition of Chinese Veterinary Pharmacopoeia, the weight average molecular weight of dextran was detected to be 5160, and the distribution coefficient was 1.22, which met the standard and could be directly used in the next reaction.

[0025] Synthesis of iron dextran: Dilute the above reaction solution to 3L, heat up to 90°C, add 600ml of 20% sodium hydroxide solution dropwise, cool dow...

Embodiment 2

[0028] Obtaining of low molecular weight dextran: Weigh 500 g of macromolecular dextran (weight average molecular weight 1982410, distribution coefficient 1.52), and add 1 L of distilled water. Raise the temperature to 70°C, stir until dissolved; add α-1,6-dextranase from Penicillium at a ratio of 100 U / g substrate, and start timing. After the reaction was carried out for 90 minutes, the temperature began to rise, and the temperature was maintained at 100° C. for 10 minutes to inactivate the enzyme activity and terminate the reaction. According to the detection method for the molecular weight of dextran in the 2010 edition of Chinese Veterinary Pharmacopoeia, the weight average molecular weight of dextran was detected to be 5580, and the distribution coefficient was 1.35, which met the standard and could be used for the next reaction.

[0029] Synthesis of iron dextran: Take the above reaction solution, heat up to 65°C, add 13ml of dimethyl sulfoxide, 40ml of 30% hydrogen pero...

Embodiment 3

[0032]Obtaining low molecular weight dextran: Weigh 100g of macromolecular dextran (weight average molecular weight 7156, distribution coefficient 1.14), add it to 2L distilled water, raise the temperature to 35°C, stir until dissolved; add hair shell according to the ratio of 5U / g substrate α-1,6-dextranase derived from Bacteria, start the timer. After the reaction was carried out for 15 minutes, the temperature began to rise, and the temperature was kept at 100° C. for 10 minutes to inactivate the enzyme activity and terminate the reaction. According to the detection method for the molecular weight of dextran in the 2010 edition of Chinese Veterinary Pharmacopoeia, the weight-average molecular weight of dextran was detected to be 5233, and the distribution coefficient was 1.17, which met the standard and could be directly used in the next reaction.

[0033] Synthesis of iron dextran: take the above reaction solution, heat up to 90°C, then add 50ml of 20% sodium hydroxide sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com