Surface-modified pyrolytic carbon material, battery and preparation method and application of surface-modified pyrolytic carbon material

A surface modification and pyrolysis carbon technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of low initial charge and discharge efficiency, and achieve low cost, good adaptability and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

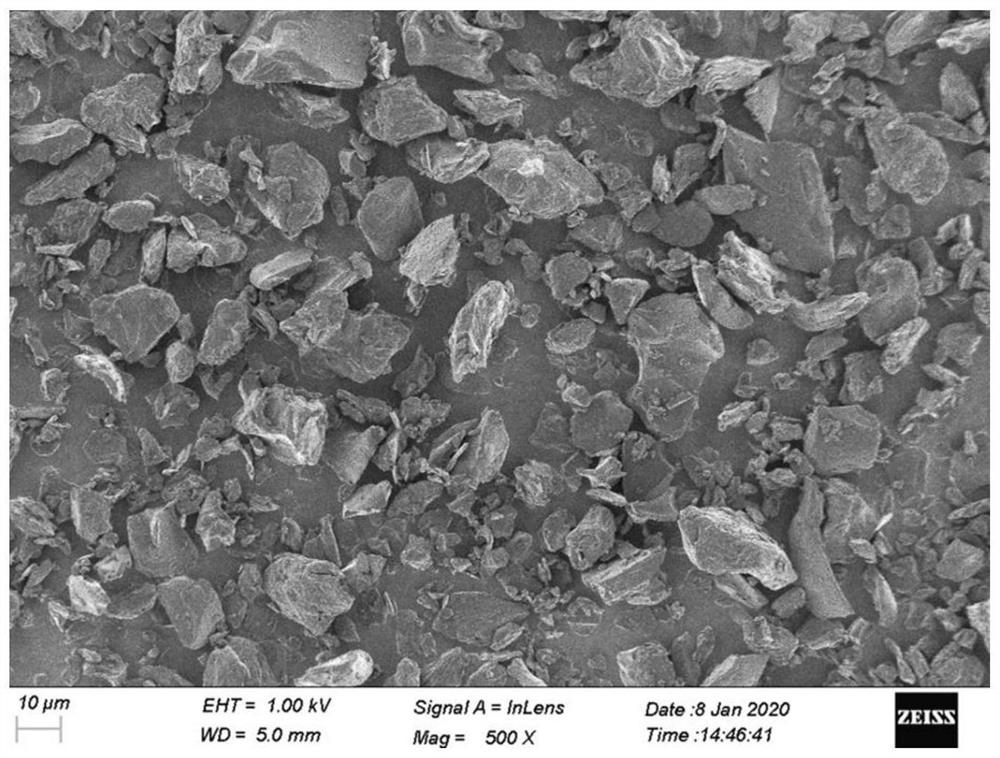

Image

Examples

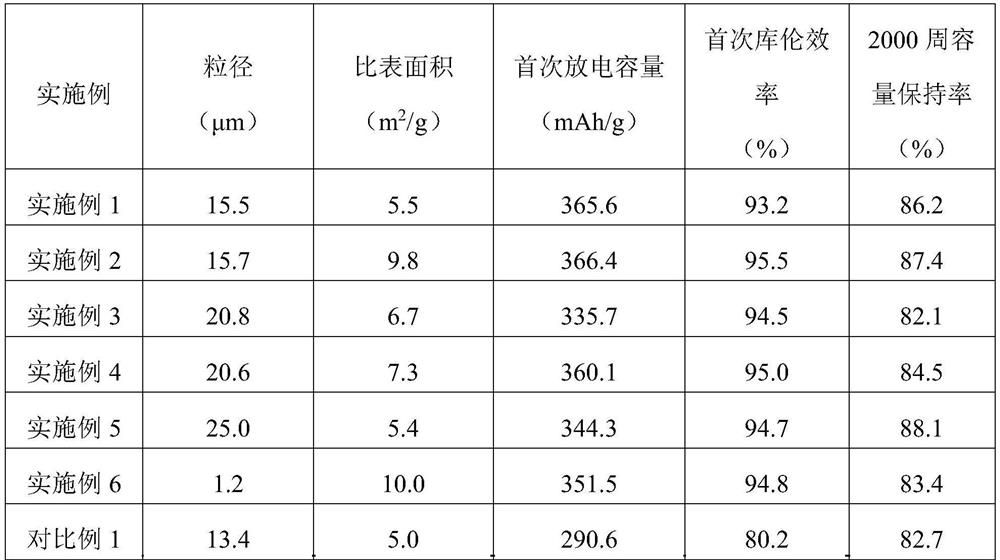

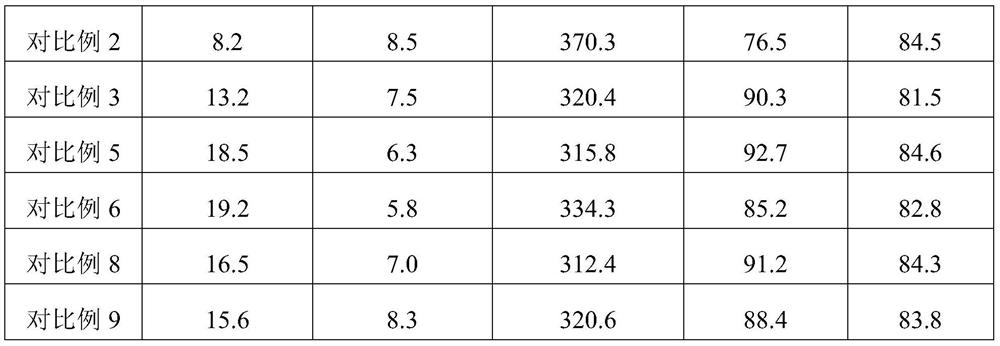

Embodiment 1

[0044] Step (1): The coal tar pitch is heated up in the reactor to carry out the polymerization reaction. The temperature of the polymerization reaction is 100 ° C, the time of the polymerization reaction is 6 hours, and the material is discharged at room temperature; the material is transferred to the jet mill for jet pulverization and classification. Material A was obtained, and the particle size of material A was 15.6 μm;

[0045] Step (2): The material A and heavy oil coating agent prepared in step (1) are alternately added to the coating kettle under the condition of stirring, and the surface coating is carried out under the protection of nitrogen. Material A and heavy oil The mass ratio of oil to oil is 12:1; the surface coating temperature is 300°C, and the surface coating time is 3 hours to obtain material B;

[0046] Step (3): Under the protection of nitrogen, material B was carbonized at 1100°C for 4 hours; after that, the reaction product was cooled to room temperat...

Embodiment 2

[0048] Step (1): The coal tar pitch is heated up in the reactor to carry out the polymerization reaction, the temperature of the polymerization reaction is 150°C, the time of the polymerization reaction is 10h, and the material is discharged at room temperature; the material is transferred to the jet mill for jet pulverization and classification, Material A was prepared, and the particle size of material A was 20.8 μm;

[0049] Step (2): The material A and heavy oil coating agent prepared in step (1) are alternately added to the coating kettle under the condition of stirring, and the surface coating is carried out under the protection of nitrogen. Material A and heavy oil The mass ratio of oil to oil is 14:1; the surface coating temperature is 450°C, and the surface coating time is 5 hours to obtain material B;

[0050] Step (3): Under the protection of nitrogen, material B was carbonized at 1000°C for 3 hours; then the reaction product was cooled to room temperature, and then...

Embodiment 3

[0052] Step (1): Coal tar pitch is heated in the reaction kettle to carry out polymerization reaction. The temperature of the polymerization reaction is 200 ° C, the time of the polymerization reaction is 1 h, and the material is discharged at room temperature; the material is transferred to the jet mill for jet pulverization and classification, Material A is obtained, and the particle size of material A is 10.5 μm;

[0053] Step (2): The material A and the coal tar coating agent prepared in step (1) are alternately added to the coating kettle under the condition of stirring, and the surface coating is carried out under the protection of nitrogen, and the material A and the heavy The mass ratio of oil is 18:1; the surface coating temperature is 600°C, and the surface coating time is 5 hours to obtain material B;

[0054] Step (3): Under the protection of nitrogen, material B was carbonized at 1500°C for 2 hours; after that, the reaction product was cooled to room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com