Through die for producing green brick tea

A technology of green brick tea and mold, applied in the direction of tea processing before extraction, can solve the problems of low production efficiency, complex structure, difficult to adapt to the requirements of mechanized production, etc., and achieve the effect of improving efficiency and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

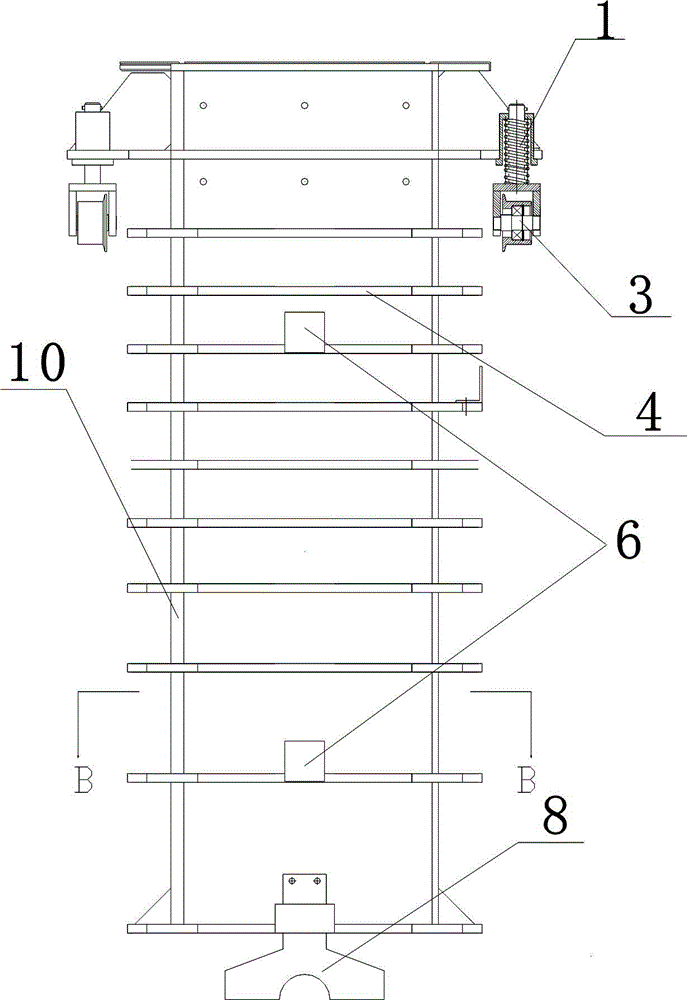

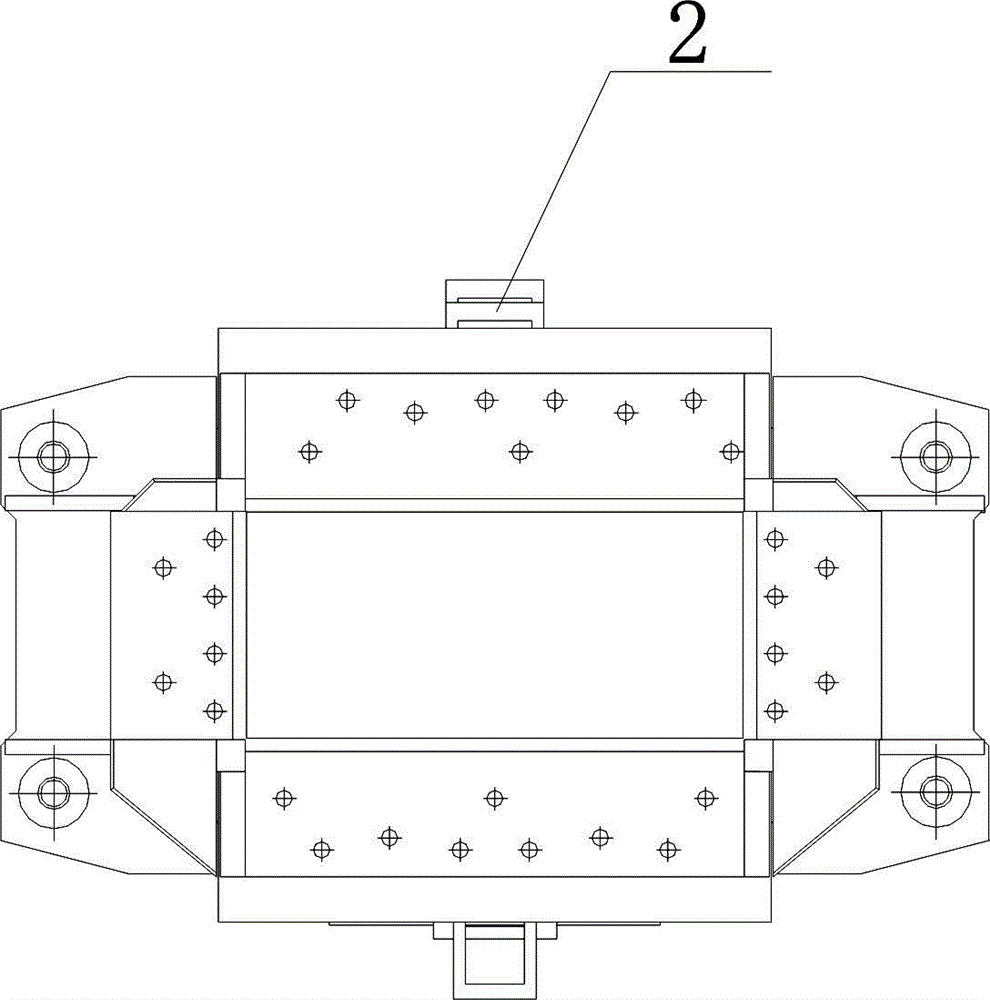

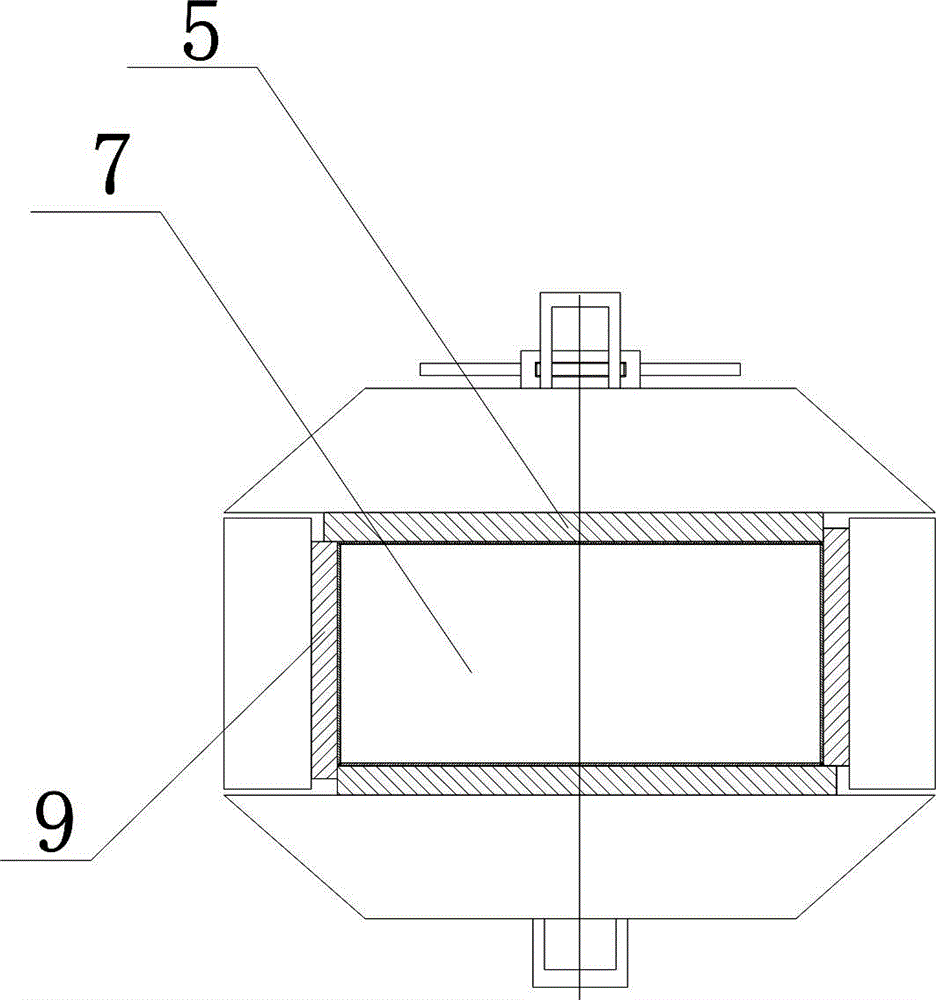

[0017] Such as Figure 1~Figure 3 Shown, a kind of green brick tea straight-through mold, mold 10 is provided with the hollow inner cavity 7 that is used to press green brick tea, and this hollow inner cavity 7 is provided with upper mouth, lower mouth. The upper part of the mold 10 is provided with a roller assembly, and the lower part of the mold 10 is provided with a scraper 8. After the mold 10 moves, the scraper 8 can take the extruded tea bricks out together, which can reduce the trouble of manually taking bricks.

[0018] The hollow inner cavity 7 is welded by two straight plates 5 and two baffles 9, and the materials of the straight plates 5 and the baffles 9 are both Q345 steel with a thickness of 18mm.

[0019] After the mold 10 is completed, measure the size of the hollow cavity 7 of the mold 10, and customize the aluminum alloy template according to the size of the hollow cavity 7. The size of the aluminum alloy template and the size of the hollow cavity 7 can achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com