Block poly-carboxylic acid concrete high-efficiency water reducing agent and preparation method thereof

A high-efficiency water reducer and polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems that it is difficult to meet the new and higher requirements of concrete, and the development space is not large, so as to achieve narrow molecular weight distribution, improve fluidity, and molecular weight controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Step 1): Add 10g polyethylene glycol monomethyl ether acrylate monomer (Mw=400), 25g DMF, 111.68mg to a four-necked flask equipped with a thermometer, stirrer, reflux condenser and rubber stopper CuBr 2 , 156.2mg bipyridyl and 88mg ascorbic acid, pass into N 2 Oxygen in the reaction vessel and the reaction medium was removed, and the temperature was raised to 90° C. with stirring. After 30 minutes, 97.53 mg of initiator 2-bromoisobutyrate ethyl was added to initiate the polymerization reaction for 12 hours.

[0055] 2) After separating the homopolymer and small molecules with tetrahydrofuran, add 9g of sodium methacrylate and 35g of water into the highly viscous reaction mixture. After reacting for 18 hours, cool naturally below 40°C to obtain a copolymer solution.

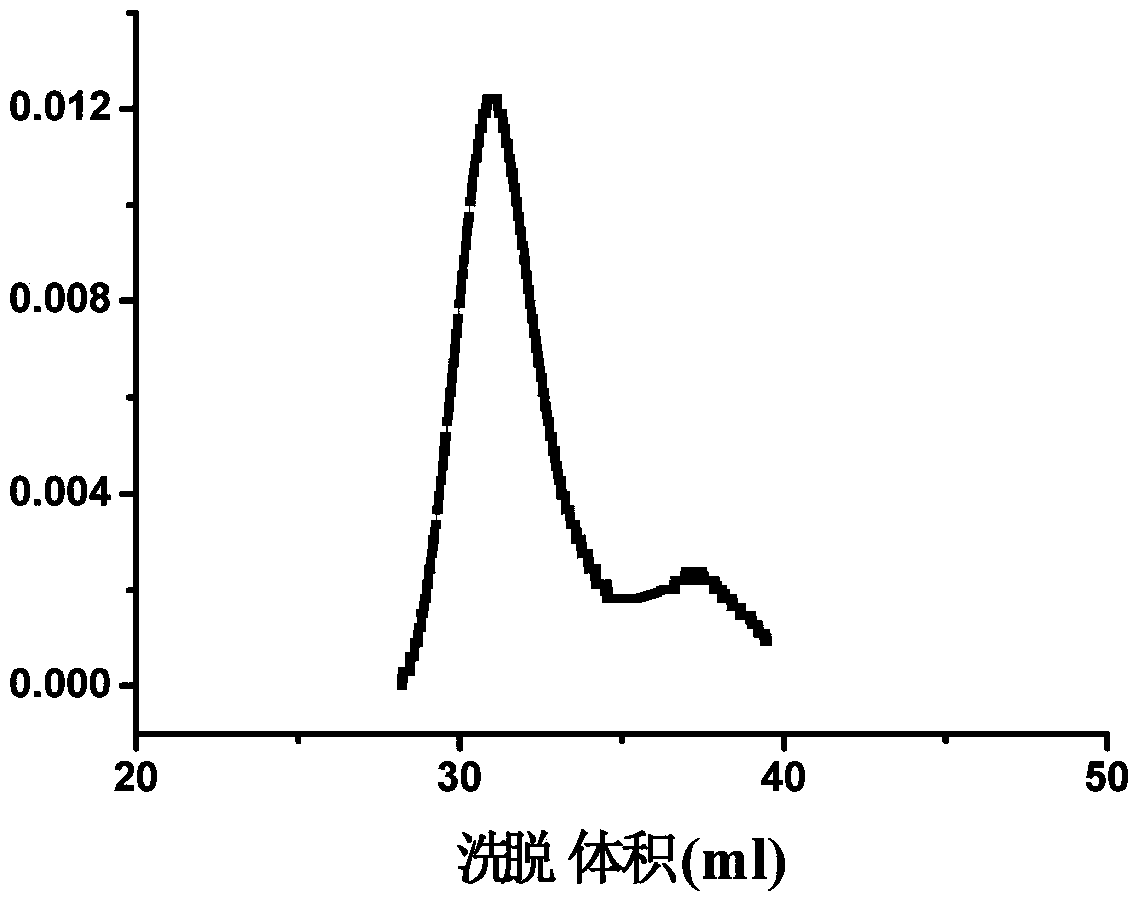

[0056] The pH value of the copolymer solution is about 7-8, the solid content is 34.12%, the weight average molecular weight of the copolymer is 20355g / mol, and the PDI=1.39.

Embodiment 2

[0058] Step 1): According to the procedure described in Example 1, 27.5g of polypropylene glycol mono(meth)acrylate monomer (Mw=1100), 55.42g of methanol, 89.66mg of CuBr, and 216.63mg of pentamethyl were sequentially added to the reaction vessel Diethylenetriamine, through N 2 The oxygen in the reaction vessel and the reaction medium was removed, and the temperature was raised to 55° C. with stirring. After 30 minutes, 104.38 mg of the initiator methyl 2-bromopropionate was added to initiate the polymerization reaction for 7 hours.

[0059] Step 2): After separating the homopolymer and small molecules with tetrahydrofuran, add 13.5g of sodium methacrylate and 87g of water into the highly viscous reaction mixture, react for 18 hours, and naturally cool to below 40°C to obtain the copolymer substance solution.

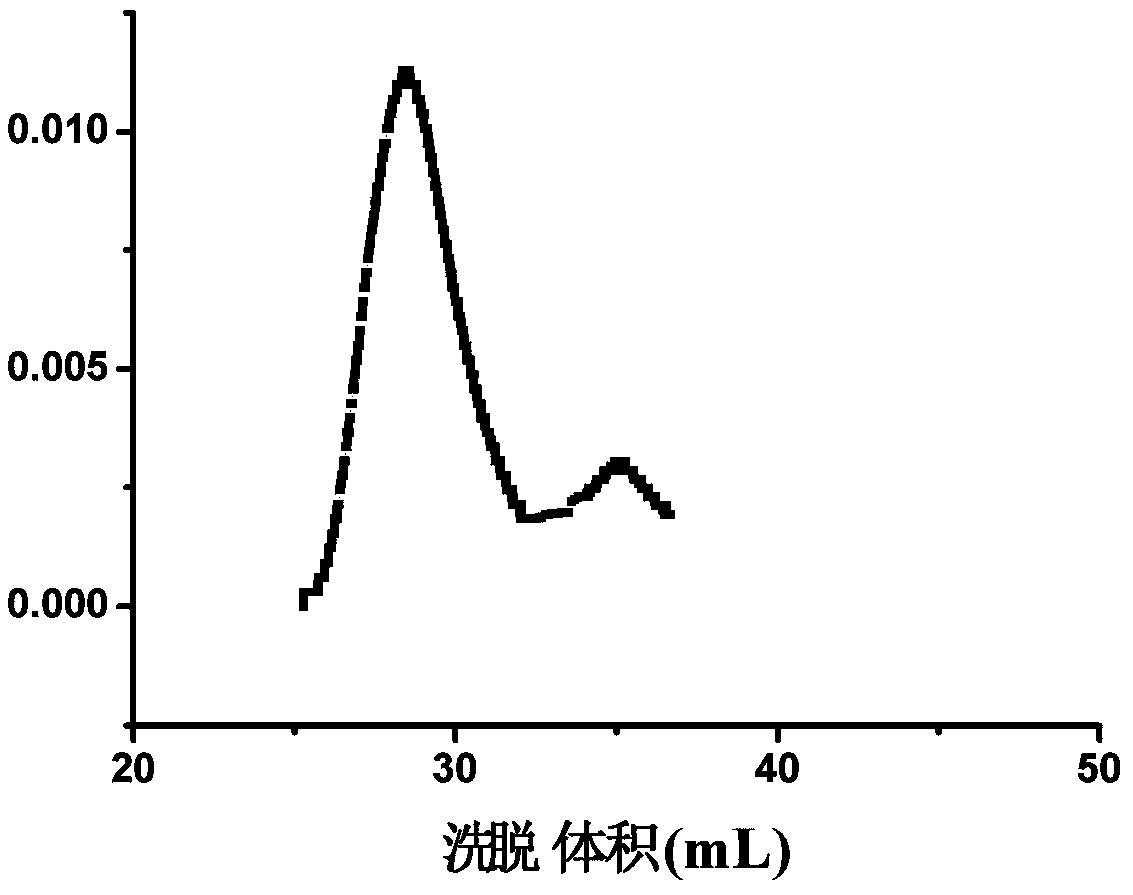

[0060] The pH value of the copolymer solution is about 7~8 (solid content 31.85%), the weight average molecular weight of the copolymer is 39672g / mol, and PDI=1.31.

Embodiment 3

[0062] Step 1) According to the procedure described in Example 1, 23.75g of polyethylene glycol monomethyl ether acrylate monomer (Mw=950), 55.42g of anisole, 35.35mg of CuCl, 164.56mg of three (2-Dimethylaminoethyl)amine, through N 2 The oxygen in the reaction vessel and the reaction medium was removed, and the temperature was raised to 90°C with stirring. After 30 minutes, 63.86 mg of the initiator 2-bromoisopropionyl bromide was added to initiate the polymerization reaction for 16 hours.

[0063] Step 2) After separating the homopolymer and small molecules with tetrahydrofuran, 11.75g of sodium acrylic acid and 107g of water were added to the highly viscous reaction mixture. After reacting for 18 hours, it was naturally cooled to below 40°C to obtain a copolymer solution.

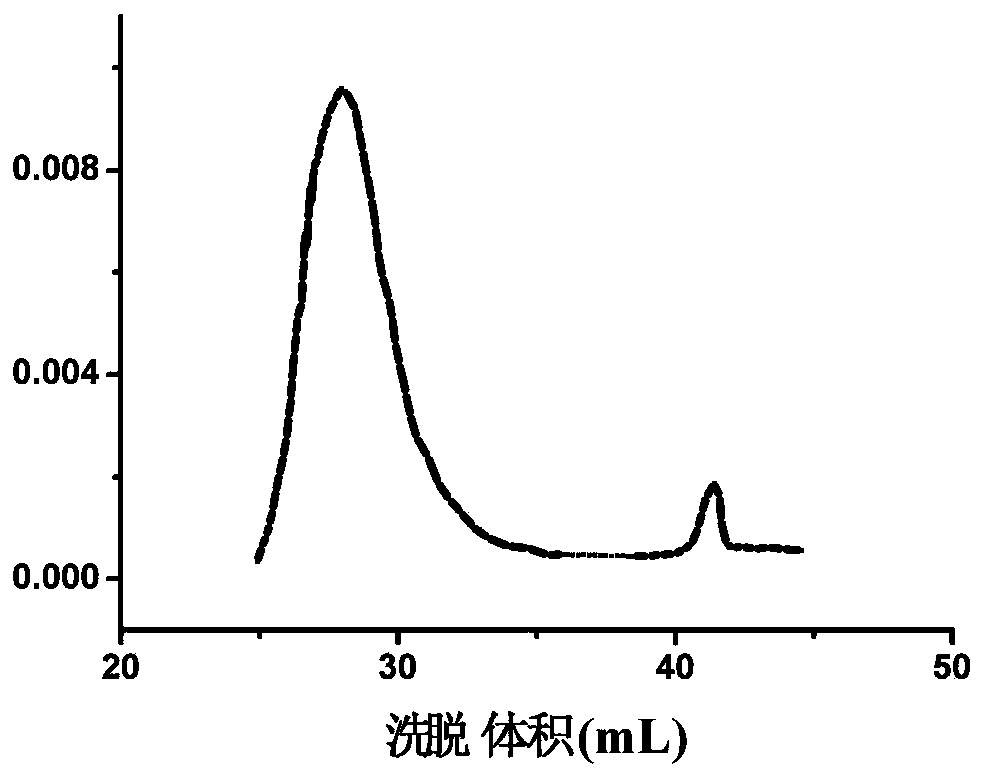

[0064] The pH value of the copolymer solution is about 7~8 (solid content 24.37%), the weight average molecular weight of the copolymer is 80541g / mol, and PDI=1.23.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com