Valve part for a control valve for control of pressure medium flows

A pressure medium, control valve technology, applied in valve devices, multi-port valves, engine components, etc., can solve problems such as pressure imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

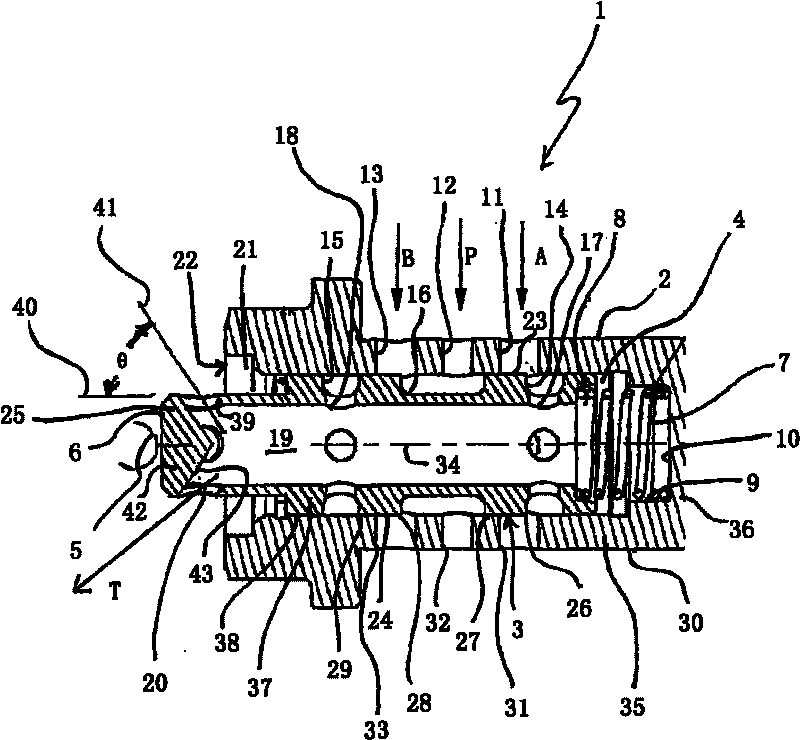

[0031] The electromagnetic control valve shown in FIG. 4 has been introduced in detail in the introduction of the specification according to the classification of traditional valve parts, so no further description will be made here.

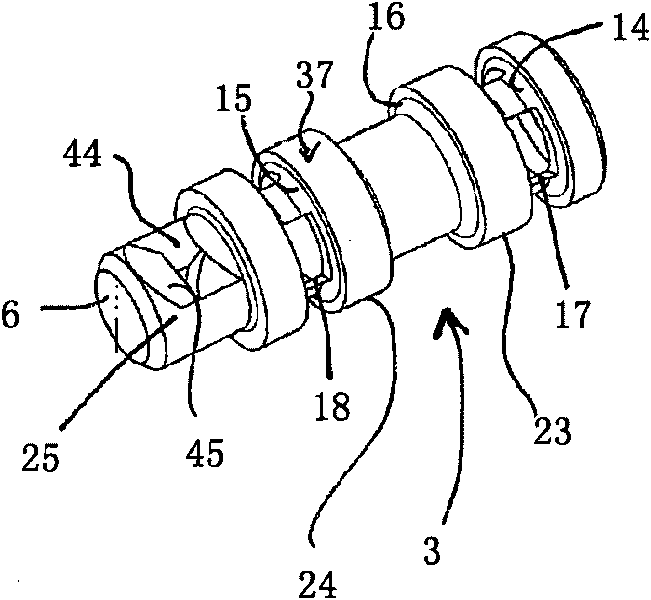

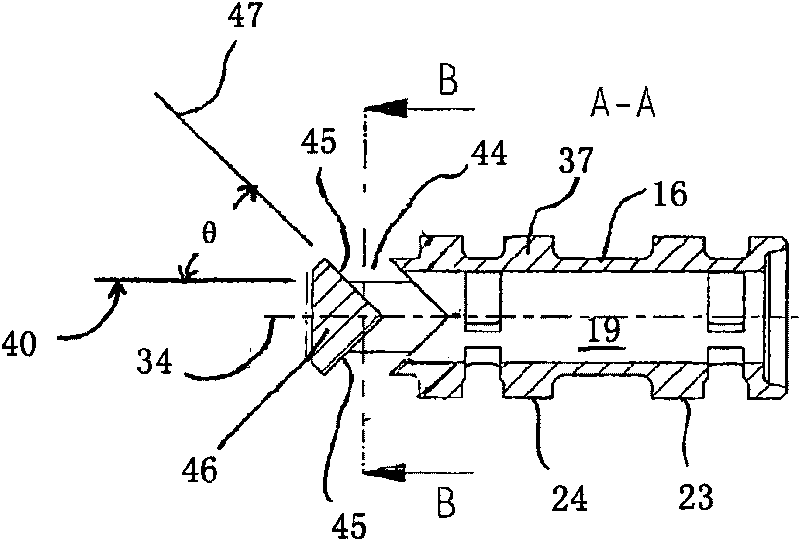

[0032] Figures 1 to 3 An exemplary embodiment of a valve element according to the invention for a solenoid control valve of a camshaft adjuster for an internal combustion engine is shown.

[0033] first observe figure 1 , wherein a first embodiment of the valve member according to the invention is shown in axial section. In particular a solenoid control valve for pressure medium regulation of a hydraulic camshaft adjuster of an internal combustion engine. The valve part 1, designated as a whole by the reference numeral 1, comprises a substantially hollow cylindrical valve housing 2, which has an axially (parallel A first cylinder outer section 35 on the cylinder axis 34 ) and a first cylinder base section 36 extending perpendicular to the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com