Method for preparing chitosan oligosaccharide from papain through freeze drying

A papain and chitosan oligosaccharide technology, which is applied in the field of oligosaccharide preparation, can solve the problems of low molecular weight of chitosan oligosaccharide, difficult reaction control, complicated preparation steps, etc., and achieves convenient drug storage, good industrial promotion practicability and value , the effect of uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, preparation of chitosan oligosaccharide and reducing sugar content determination experiment

[0030] 1. Preparation of Chitooligosaccharide by Enzymatic Hydrolysis of Papain

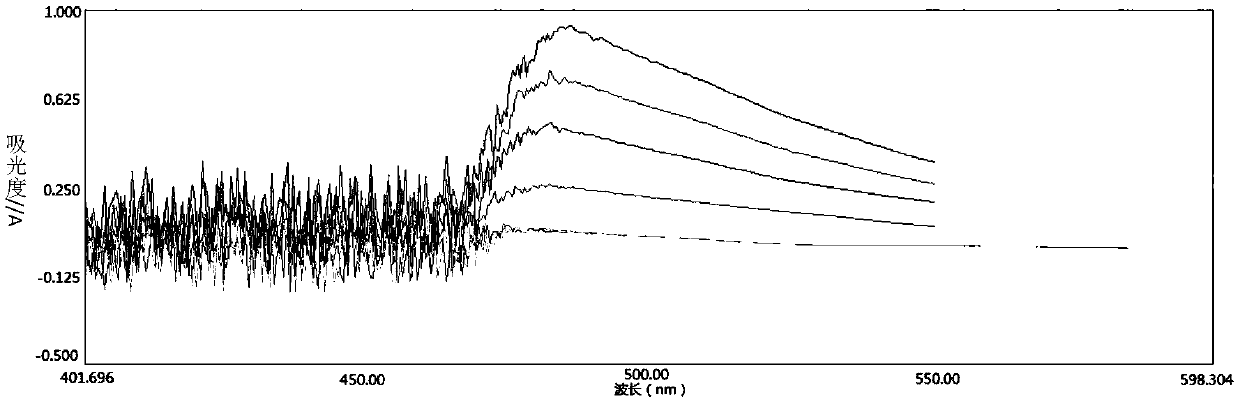

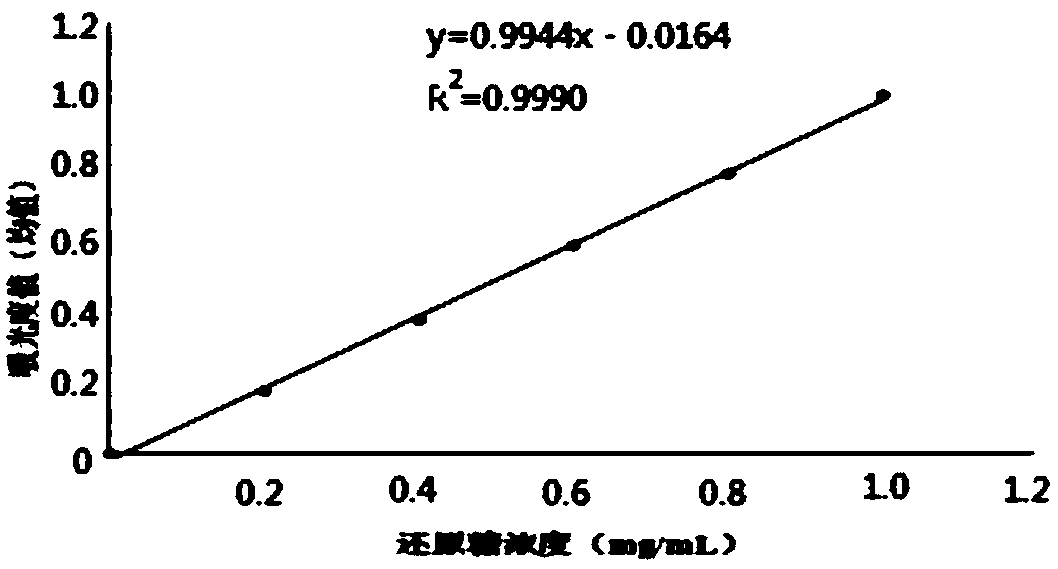

[0031] In the 25 milliliter colorimetric tube, add the mass concentration of 10mLpH4.5 and be 1.0% chitosan solution, add the papain solution that mass concentration is 1.0%, make the enzyme base mass ratio be 5%, in the water bath environment of 45 ℃ , water bath for 2h, after 2h, take out the boiling water bath for 10min to inactivate, cool to room temperature with running water and filter, discard the filter residue, take 0.5mL filtrate (or less, determined according to absorbance) in a 10mL colorimetric tube, add distilled water to 1mL, Then add 1.0mL DNS reagent, develop color in a boiling water bath for 5min, take it out, cool it to room temperature with running water, and set the volume to 10mL, use the blank tube as a reference, and measure the absorbance value at the maximum...

Embodiment 2

[0037] Embodiment 2, papain enzymatic hydrolysis prepares chitosan oligosaccharide condition optimization experiment

[0038] 1. Substrate concentration single factor experiment

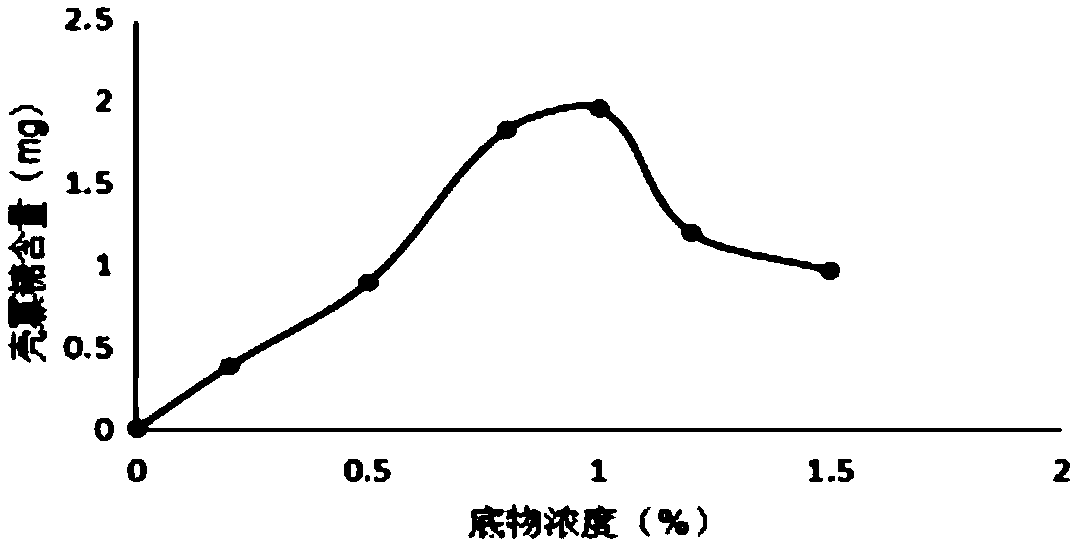

[0039] Under the condition that the mass ratio of fixed enzyme substrate is 5%, the enzymolysis time is 2h, and pH4.5, the selected substrate concentration (chitosan mass concentration) is respectively 0, 0.2%, 0.5%, 0.8%, 1.0%, 1.2%, 1.5%, by measuring the chitosan oligosaccharide content after the reaction as an evaluation index, the impact of the chitosan concentration on the chitosan oligosaccharide content was investigated. The experimental results of the impact of chitosan concentration on chitosan oligosaccharide content are as follows: image 3 shown. Depend on image 3 It can be seen that under the same enzymolysis conditions, the mass ratio of the enzyme substrate is 5%, the enzymolysis time is 2h, pH4.5, and the chitosan oligosaccharide content first increases with the concentration of ...

Embodiment 3

[0051] Embodiment 3, freeze-drying process optimization experiment

[0052] In the investigation of the liquid loading area of freeze-drying, it is known that the diameter of the tray is 180mm, and the thickness of the liquid loading should not exceed 10mm. Prepare a 5% chitosan oligosaccharide solution, take a certain volume in 5 identical trays, make the thickness of the carrier liquid be 1mm, 3mm, 5mm, 7mm, 9mm, and then put it into a freeze dryer for slow freezing. To freeze the material, wait until the temperature of the cold hydrazine and the temperature of the material remain unchanged, and the naked eye judges that the cold hydrazine is completed before vacuum sublimation. The relationship between the thickness of the carrier liquid and the freeze-drying time is as follows: Image 6 shown.

[0053] Depend on Image 6 It can be obtained that the smaller the thickness of the carrier liquid, the faster the temperature will drop in the same low-temperature atmosphere,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com