Preparation method of fish collagen combined chitosan biological dressing

A fish collagen and biological dressing technology, applied in medical science, absorbent pads, fermentation, etc., can solve the problems of loss of biological activity, long time required, poor product safety, etc., achieve uniform molecular weight distribution, promote wound healing, and shorten production. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

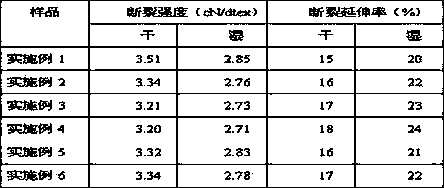

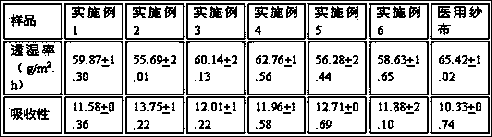

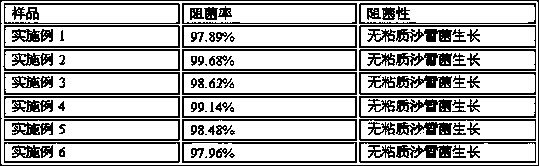

Examples

Embodiment 1

[0022] Cut the fish skin that has been cleaned of surface impurities into small pieces, and cut it into 50-mesh fish meal with a crusher; add distilled water and reaction enzyme that account for 3 times the mass of fish meal in a closed container to make a slurry, wherein the reaction enzyme is made from Composed of neutral lipase and bromelain, the amount of reaction enzyme added accounts for 0.1% of the fish meal mass, and the mass ratio of neutral lipase and bromelain is 1:4.

[0023] The prepared slurry was subjected to ultrasonic treatment at 1.5 atmospheric pressure and 15 kHz to control the reaction temperature at 50° C., pH at 7, and stir for 2 hours to carry out the enzymatic hydrolysis reaction. Add the sodium hydroxide that accounts for its quality 0.1% in the slurry after reaction, filter slurry and adjust filtrate pH value to be 5, add and account for the chitosan powder that solution gross mass is 1% in filtrate, wherein chitosan molecular weight is 300000. The ...

Embodiment 2

[0025] Cut the fish scales that have been cleaned of surface impurities into small pieces, and cut them into 100-mesh fish meal with a crusher; add distilled water and reaction enzymes that account for 5 times the mass of fish meal in a closed container to make a slurry, wherein the reaction enzymes are made from neutral It consists of lipase and alkaline protease, the amount of reaction enzyme added accounts for 0.3% of the fish meal quality, and the mass ratio of neutral lipase and alkaline protease is 1: 4.

[0026] The prepared slurry was treated under 2 standard atmospheric pressure and 20 kHz ultrasonic treatment to control the reaction temperature to 55° C., pH to 7.5, and stirred for 1.5 h to carry out the enzymatic hydrolysis reaction. Add the sodium hydroxide that accounts for its quality 0.2% in the slurry after reaction, filter slurry and adjust filtrate pH value to be 6, add and account for the chitosan powder that solution gross mass is 5% in filtrate, wherein chi...

Embodiment 3

[0028] Cut the swim bladder that has been cleaned of surface impurities into small pieces, and cut it into 150-mesh fish meal with a crusher; add distilled water and reaction enzymes that account for 7 times the mass of fish meal in a closed container to make a slurry, wherein the reaction enzymes are made of neutral It consists of lipase and trypsin, the amount of reaction enzyme added accounts for 0.5% of the mass of fish meal, and the mass ratio of neutral lipase to trypsin is 1:3.

[0029] The prepared slurry was subjected to 2.5 standard atmospheric pressure and 25 kHz ultrasonic treatment to control the reaction temperature to 70° C., pH to 7.5, and stirred for 1 hour to carry out the enzymatic hydrolysis reaction. Add the sodium hydroxide that accounts for its quality 0.3% in the slurry after reaction, filter slurry and adjust filtrate pH value to be 5, add and account for the chitosan powder that solution gross mass is 2% in filtrate, wherein chitosan molecular weight i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com