Preparation method of aliphatic diisocyanate tripolymer curing agent

A technology of isocyanate trimerization and diisocyanate, which is applied in the field of polyurethane curing agent preparation, can solve the problems of unsuitable surface paint, increased product viscosity, long reaction time, etc., to avoid the increase of chromaticity, uniform molecular weight distribution and stable gloss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

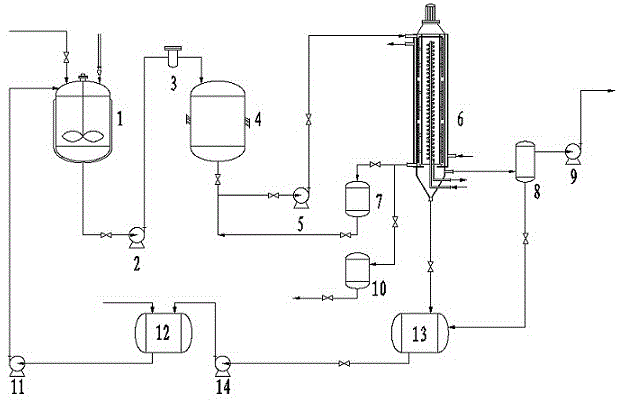

[0036] Add 1000g of HDI to the stirred reactor 1, stir, ventilate with nitrogen, heat and control the temperature at 65°C, and add octanoic acid tetramethylammonium salt catalyst from the opening of reactor 1 three times within 1 hour after the temperature is stabilized. The total amount is 0.1% of the mass of the aliphatic diisocyanate monomer. From the beginning of adding the catalyst, samples are taken every 1 hour to measure the mass percentage of free monomers and NCO groups in the reaction system. The NCO groups in the reaction system to be measured When the mass percent composition of group is 40%, add the benzoyl chloride terminator of aliphatic diisocyanate monomer quality 0.1% from the opening of reactor 1 to terminate the reaction, and send into filter 3 by discharge pump 2 after the insulation 1h Enter the mixed material storage tank 4 after filtering out most of the solid particles.

[0037]The prepolymer in the mixed material storage tank 4 enters the short-path ...

Embodiment 2

[0039] Add 1000g of HDI to the reactor 1 with stirring, stir, blow nitrogen, heat and control the temperature at 65°C, and add tetramethylammonium lactate catalyst from the opening of reactor 1 three times within 1 hour after the temperature stabilizes. The total amount is 0.1% of the mass of the aliphatic diisocyanate monomer. From the beginning of adding the catalyst, samples are taken every 1 hour to measure the mass percentage of free monomers and NCO groups in the reaction system. The NCO groups in the reaction system to be measured When the mass percent composition of group is 40%, add the benzoyl chloride terminator of aliphatic diisocyanate monomer quality 0.1% from the opening of reactor 1 to terminate the reaction, and send into filter 3 by discharge pump 2 after the insulation 1h Enter the mixed material storage tank 4 after filtering out most of the solid particles.

[0040] The prepolymer in the mixed material storage tank 4 enters the short-path evaporator 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com