A kind of method for graft copolymerization of starch and vinyl monomer

A vinyl monomer and starch technology, which is applied in the field of preparation of starch and vinyl monomer graft copolymers, can solve the problems of high viscosity, difficult mass transfer, low solid content, etc., and achieve uniform molecular weight distribution and mass transfer Ease of heat transfer and the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

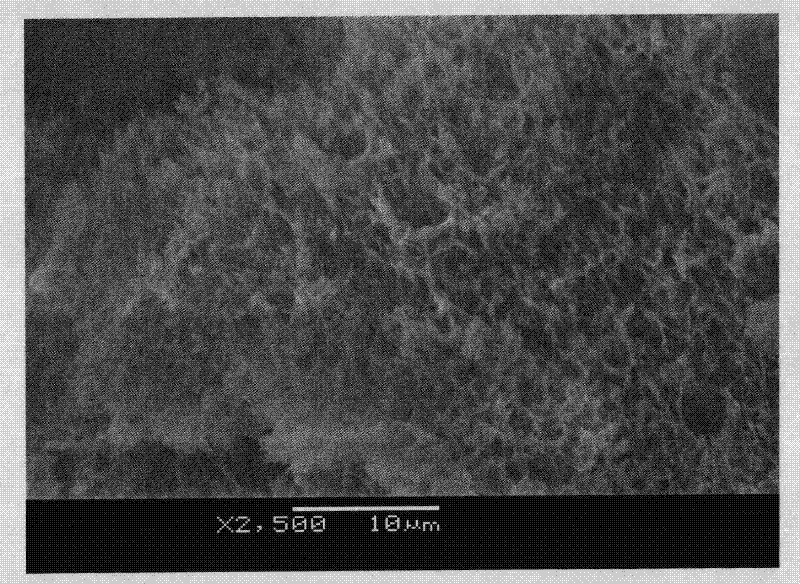

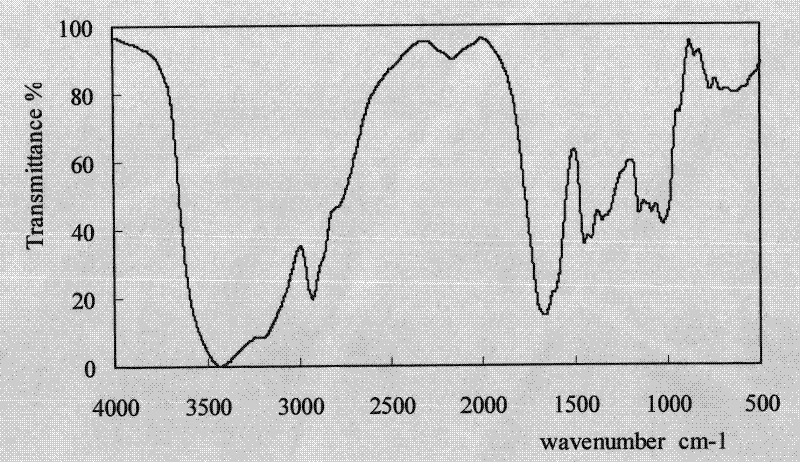

Image

Examples

Embodiment 1

[0033] ①Add a predetermined amount of cornstarch to the reactor, press m 淀粉 / m 丙烯酰胺 Add acrylamide at a ratio of 1.2 / 1, use ammonium persulfate / urea as the redox initiation system, press m 过硫酸铵 / m 尿素 1 / 5, m 过硫酸铵 / m 丙烯酰胺 Add the initiator at a ratio of 0.005 / 1, then add water equal to the total mass of the reactants, and stir evenly;

[0034] ②Raise the temperature of the reactor to 55°C under stirring;

[0035] ③ After sealing the system, inject carbon dioxide until the pressure reaches 8MPa;

[0036] ④ After 3.0 hours of constant temperature reaction, the reaction was completed to obtain a graft copolymer of starch and acrylamide.

Embodiment 2

[0038] ①Add a predetermined amount of potato starch into the reactor, press m 淀粉 / m 丙烯酸 Add moderately neutralized acrylic acid in a ratio of 2 / 1, use ammonium persulfate as the initiator, press m 过硫酸铵 / m 丙烯酸 Add the initiator at a ratio of 0.003 / 1, then add water equal to the total mass of the reactants, and stir evenly;

[0039] ②Raise the temperature of the reactor to 60°C under stirring;

[0040] ③ After sealing the system, inject carbon dioxide until the pressure reaches 24MPa;

[0041] ④ After 2.5 hours of constant temperature reaction, the reaction was completed to obtain a graft copolymer of starch and acrylic acid.

Embodiment 3

[0043] ①Add a predetermined amount of tapioca starch into the reaction kettle, press m 淀粉 / m 甲基丙烯酸 Add methacrylic acid at a ratio of 1.4 / 1, and use potassium permanganate / sulfuric acid as the initiation system, press n 高锰酸钾 / n 硫酸 1 / 5, m 高锰 酸钾 / m 甲基丙烯酸 Add the initiator at a ratio of 0.0007 / 1, then add water equal to the total mass of the reactants, and stir evenly;

[0044] ②Raise the temperature of the reactor to 40°C under stirring;

[0045] ③ After sealing the system, inject carbon dioxide until the pressure reaches 16MPa;

[0046] ④ After 1.5 hours of constant temperature reaction, the reaction was completed to obtain a graft copolymer of starch and methacrylic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com