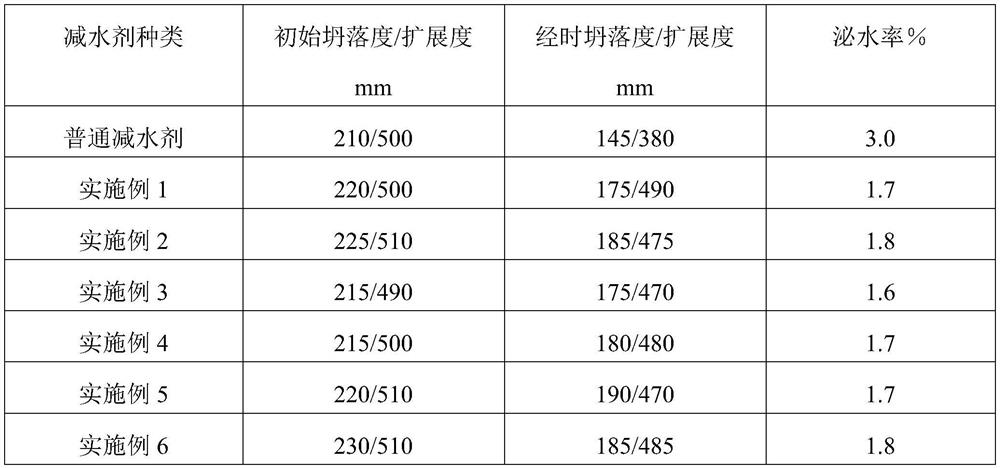

Patents

Literature

35results about How to "Promote complete reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

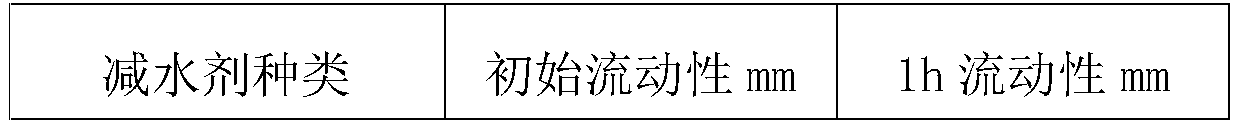

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

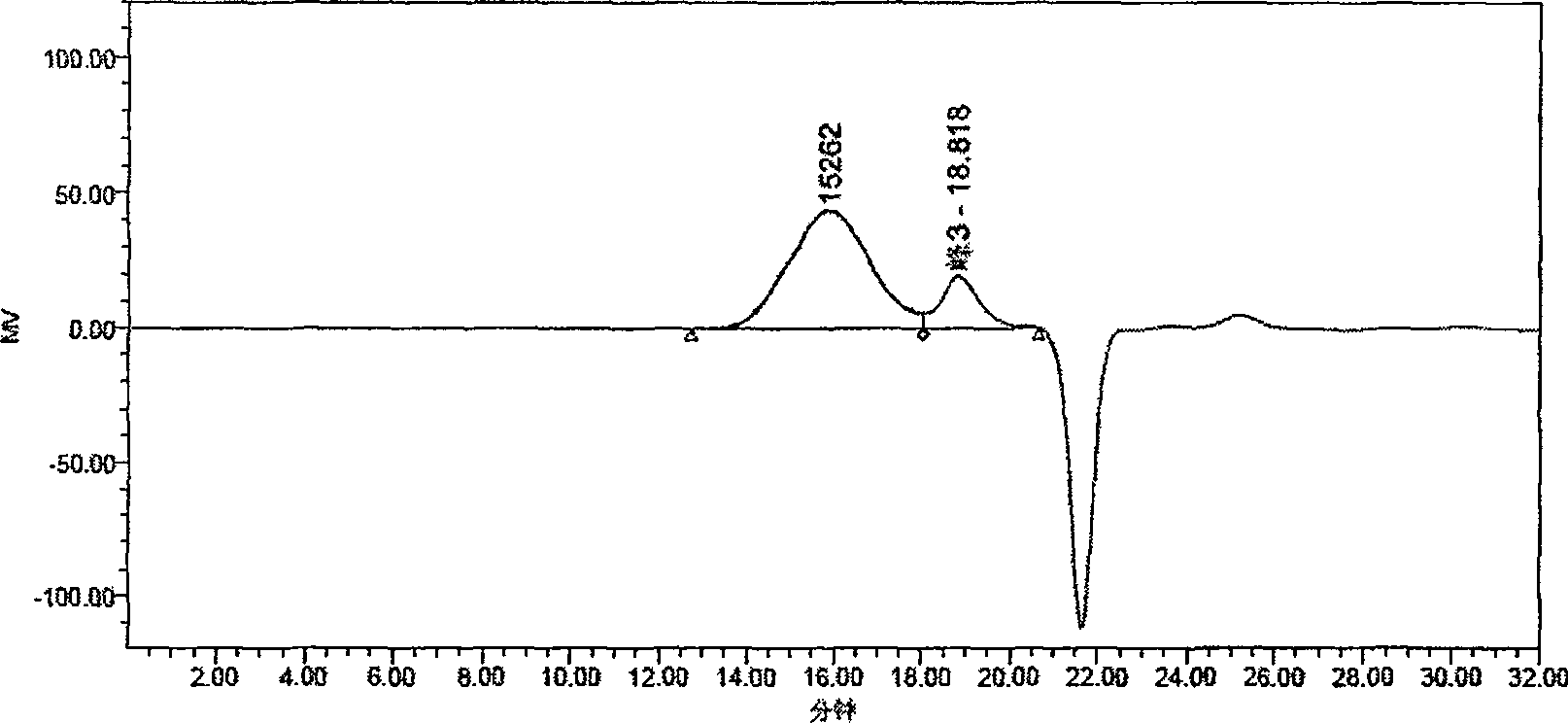

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

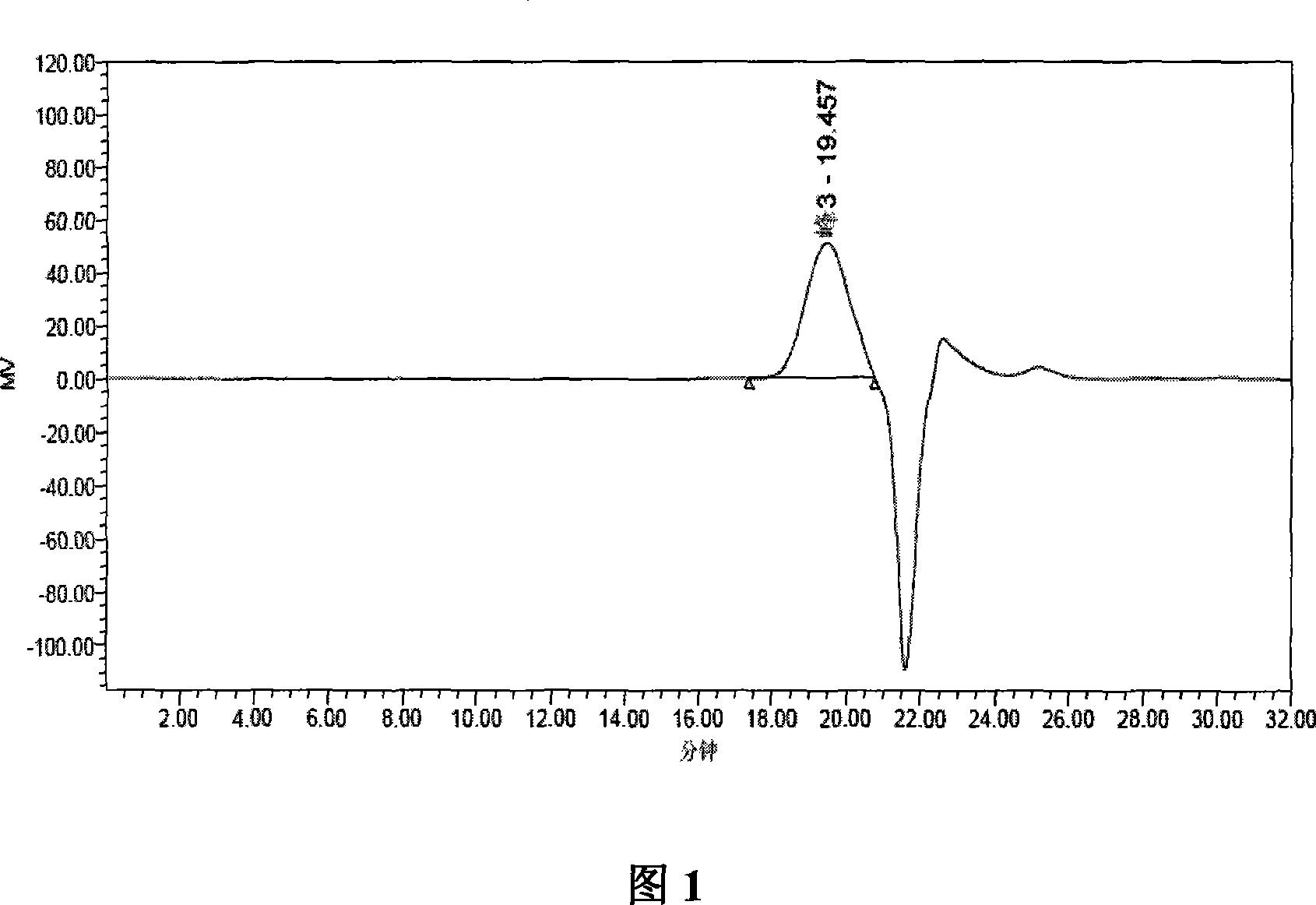

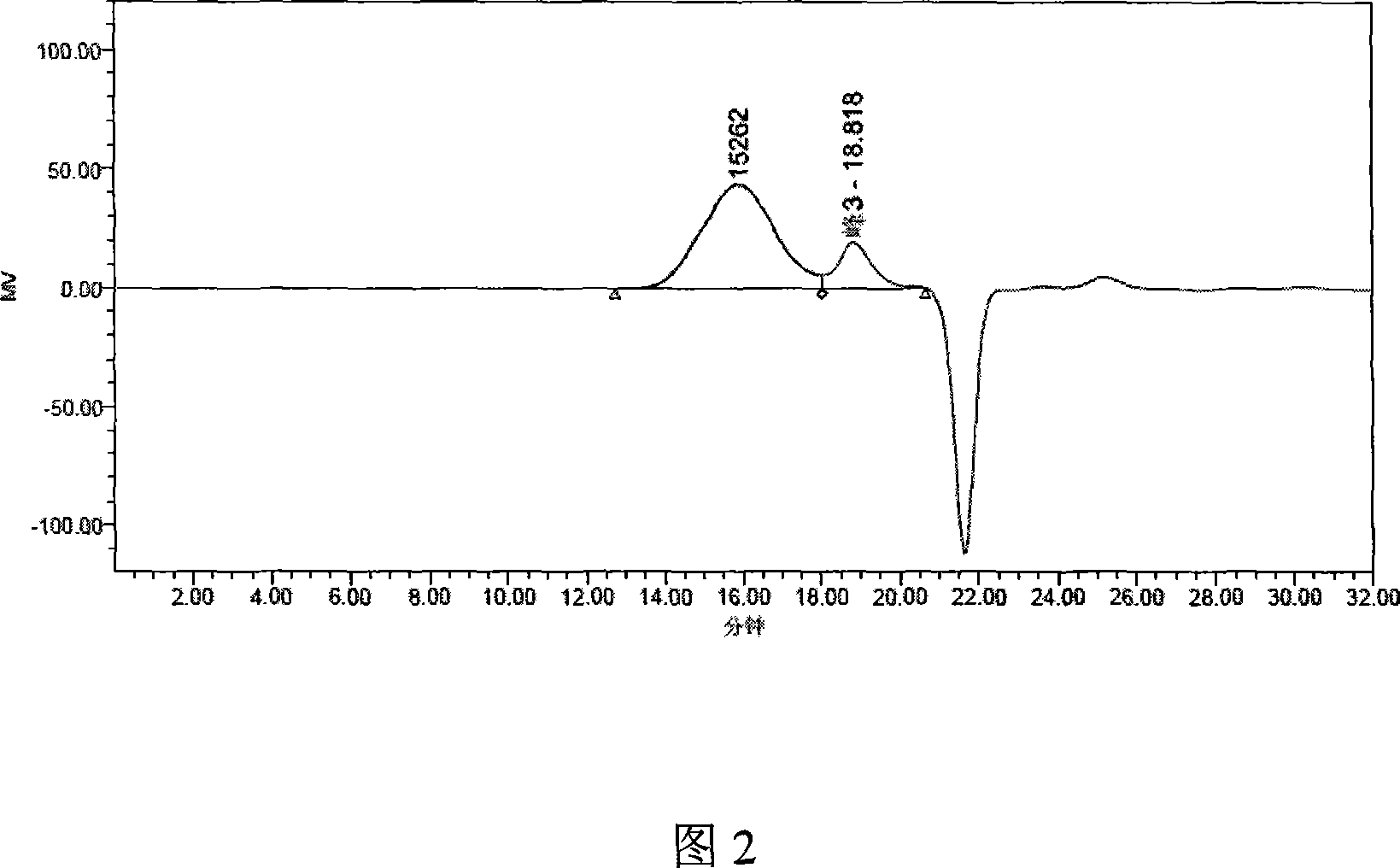

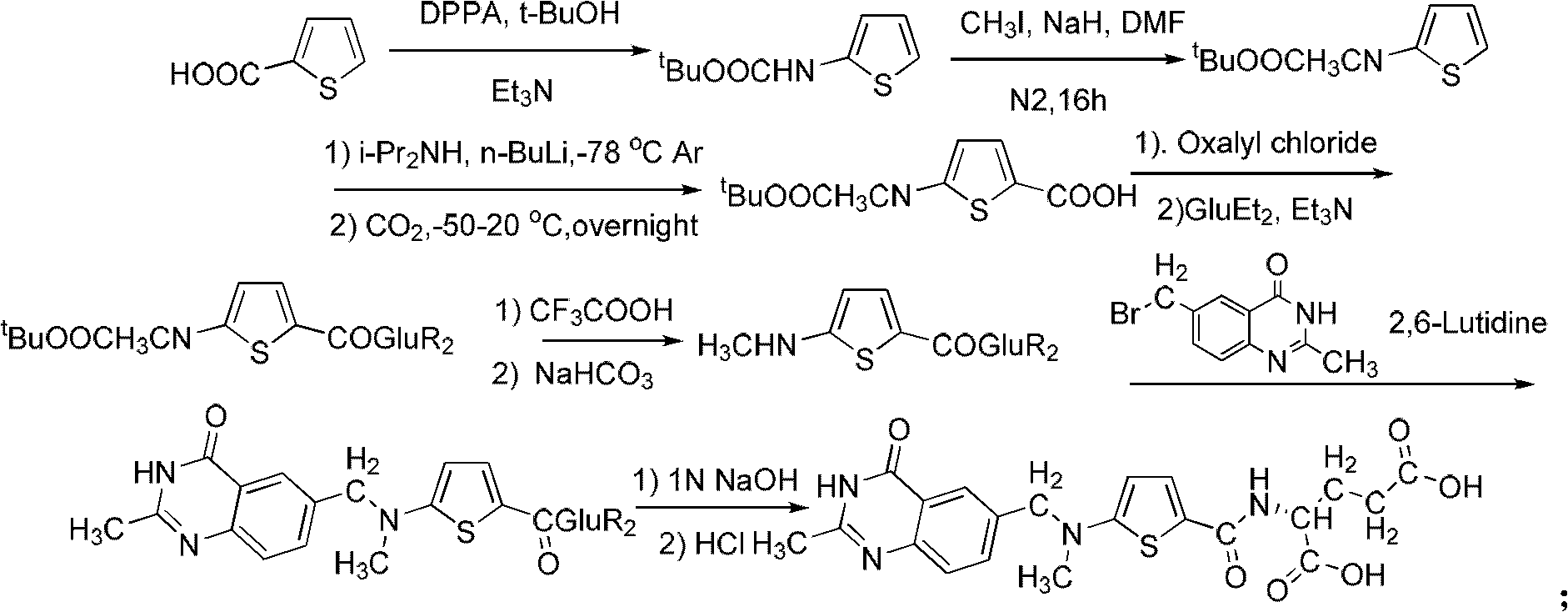

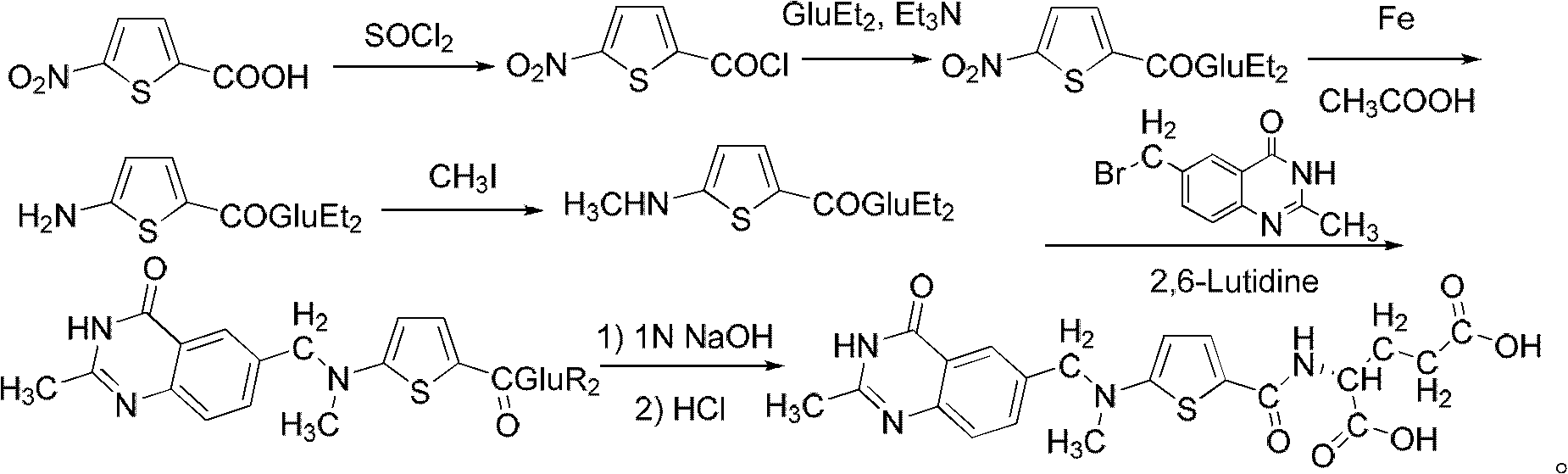

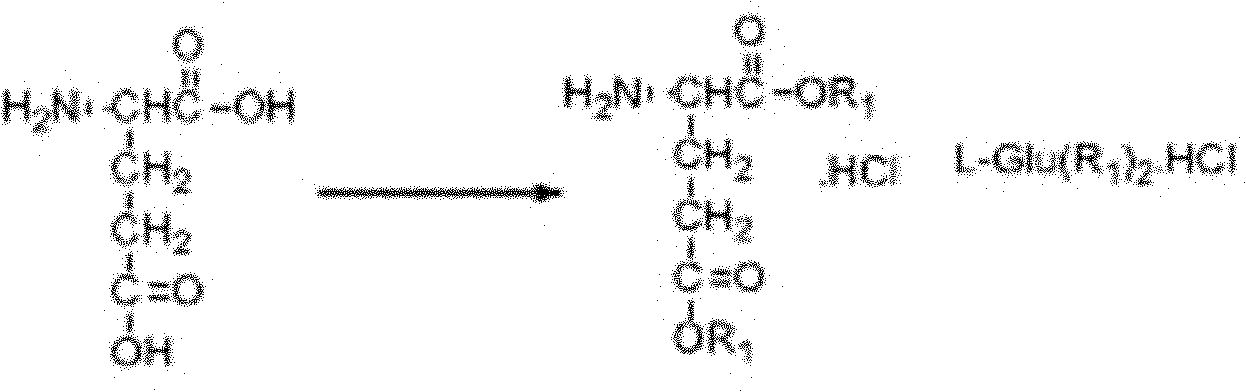

New synthesis technology of anti-cancer drug Raltitrexed

InactiveCN102127063ALow costOptimize the synthetic routeOrganic chemistryAntineoplastic agentsBenzoic acidTert-Butyloxycarbonyl protecting group

The invention relates to a new synthesis technology of anti-cancer drug Raltitrexed. The technology comprises the following steps: 1) using L-glutamic acid as raw material to perform esterification with alcohol under the action of halogenating agent and obtain L-glutamic acid diester hydrochloride; 2) using 2-amino-5-methyl-benzoic acid as raw material to prepare 6-bromomethyl-3,4-dihydro-2-methyl-4-oxo-6-quinazoline through cyclization, amination and bromination; 3) using 2-thienyl-propanedioic acid as raw material to prepare N-[5-[N-(tert-butoxycarbonyl)-N-methylamino]-2-thenoyl]-L-glutamic acid diethyl ester through nitrification, esterification, reduction, amino protection, N-methylation and device-esterification; 4) using L-glutamic acid diester hydrochloride and N-[5-[N-(tert-butoxycarbonyl)-N-methylamino]-2-thenoyl]-L-glutamic acid diethyl ester to prepare N-[5-(N-methylamino)-2-thenoyl]-L-glutamic acid diester through dehydrant condensation and deamination protection; and 5) using N-[5-(N-methylamino)-2-thenoyl]-L-glutamic acid diester and 6-bromomethyl-3,4-dihydro-2-methyl-4-oxo-6-quinazoline to perform condensation under the catalysis of alkali, recycling preparative chromatography, purifying, and performing de-esterification to obtain Raltitrexed.

Owner:深圳市普迈达科技有限公司

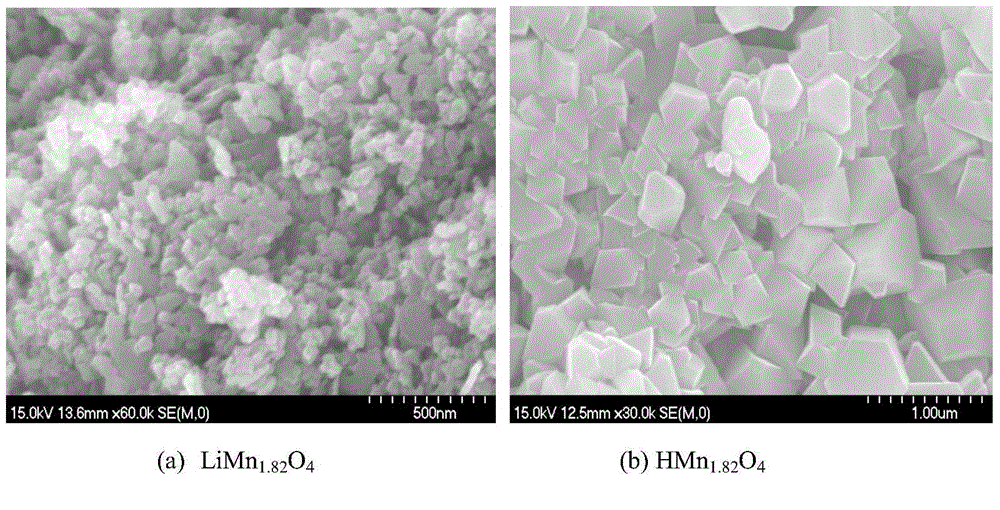

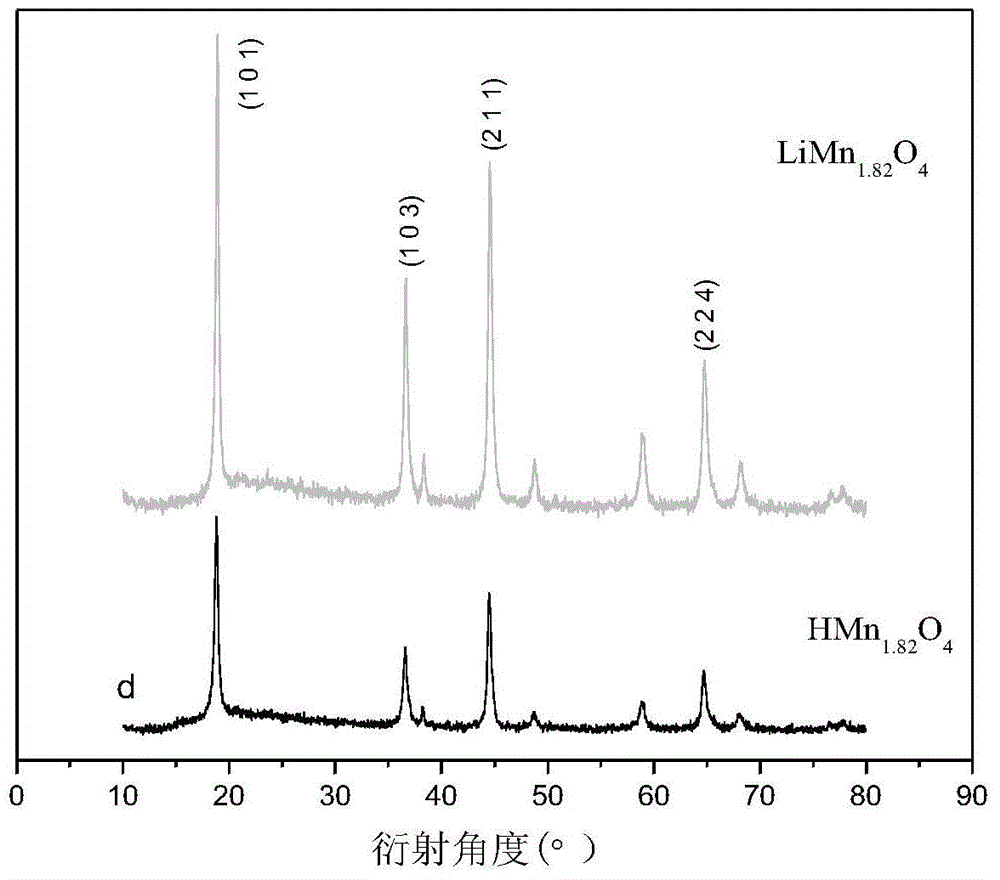

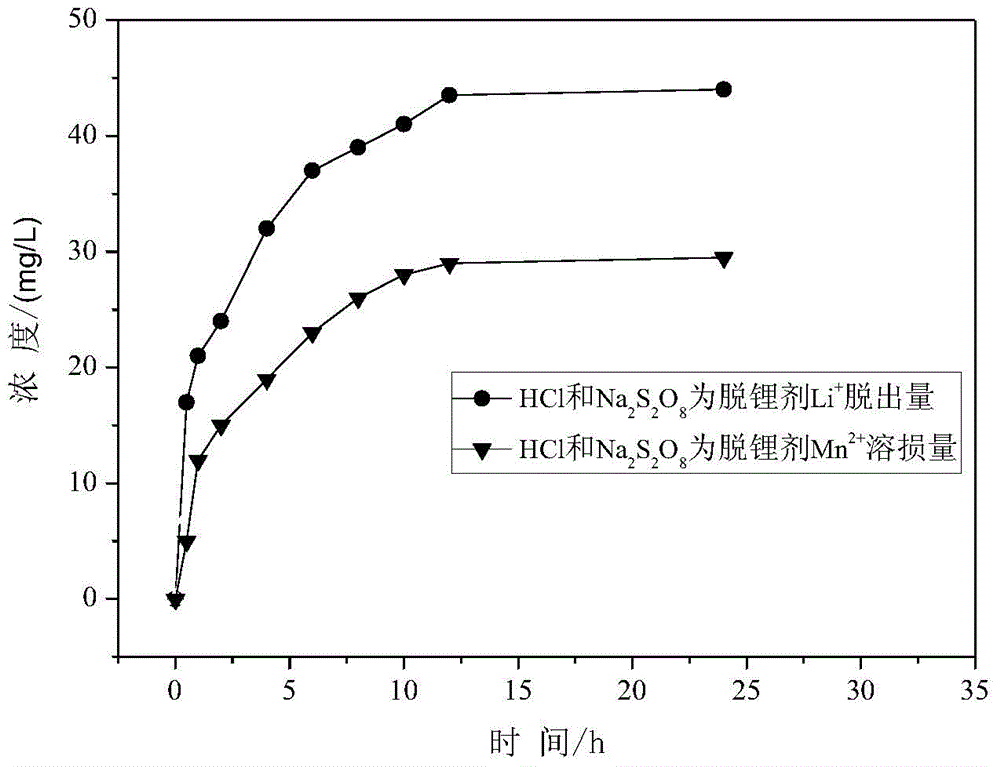

Method for preparing manganese-based lithium-ion sieve adsorbent

InactiveCN104941569ARaw materials are easy to getLow costOther chemical processesAlkali metal oxides/hydroxidesPersulfateSorbent

The invention discloses a method for preparing a manganese-based lithium-ion sieve adsorbent. The method comprises the following steps: adopting lithium hydroxide and divalent manganese salt as raw materials, dissolving the raw materials in an ethanol solution with volume fraction being 2-10%, stirring uniformly, adding H2O2 and lithium hydroxide, synthesizing an intermediate through the low-temperature hydrothermal method, obtaining lithium-ion sieve precursor through low-temperature roasting, and performing solvent dipping on the precursor to elute lithium ions so as to obtain the corresponding lithium-ion sieve adsorbent. According to the invention, the lithium-ion sieve precursor is ordered in structure and uniform in particle; hydrochloric acid and persulfate are adopted as a dipping agent of the precursor, so that the elution effect to lithium ions is good, and the manganese dissolution loss rate is greatly reduced. The whole preparation process is mild in condition and easy to control; the obtained ion sieve is high in purity and adsorbing capacity and excellent in stability, and has excellent application prospects.

Owner:ZHEJIANG UNIV OF TECH

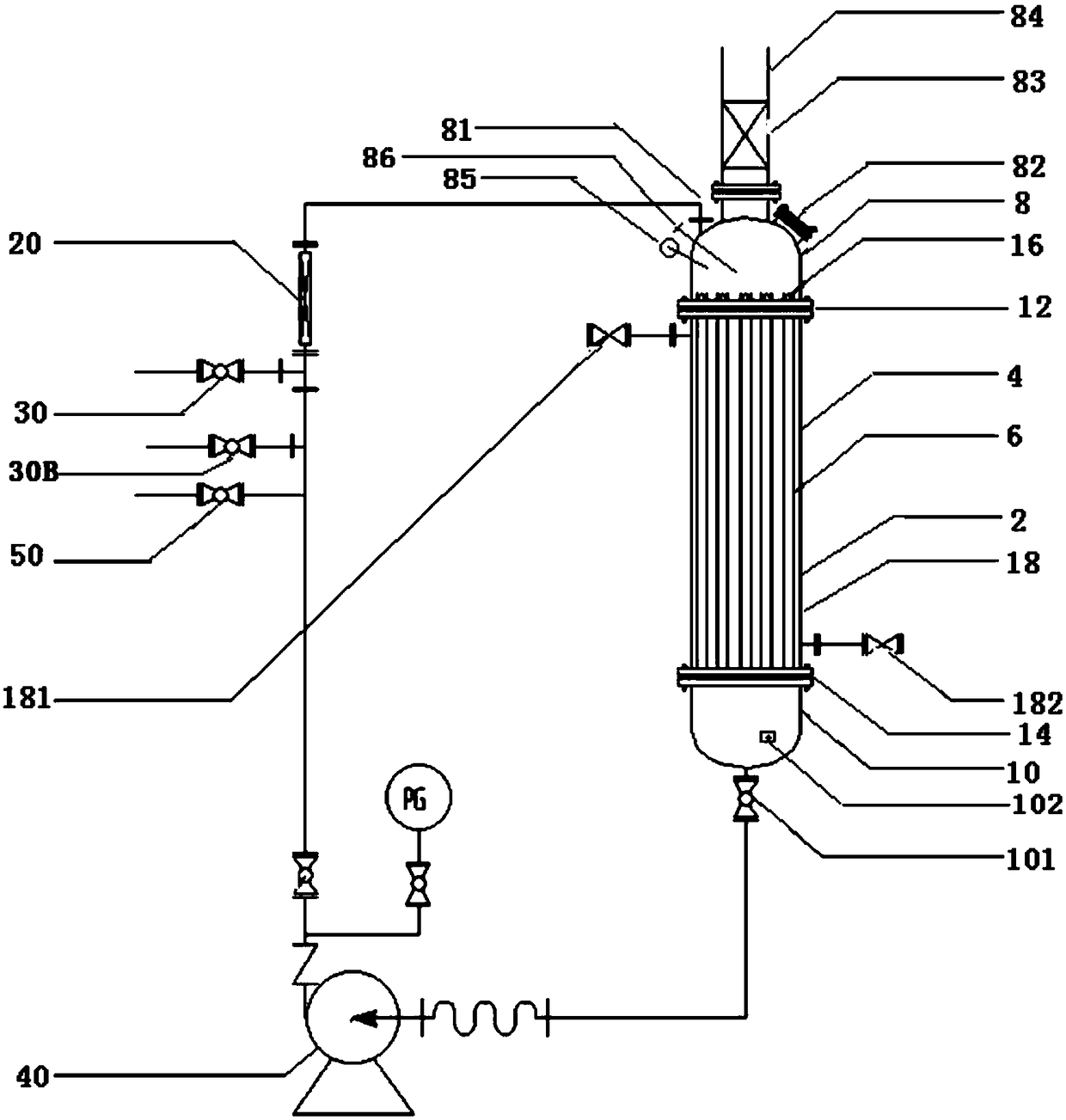

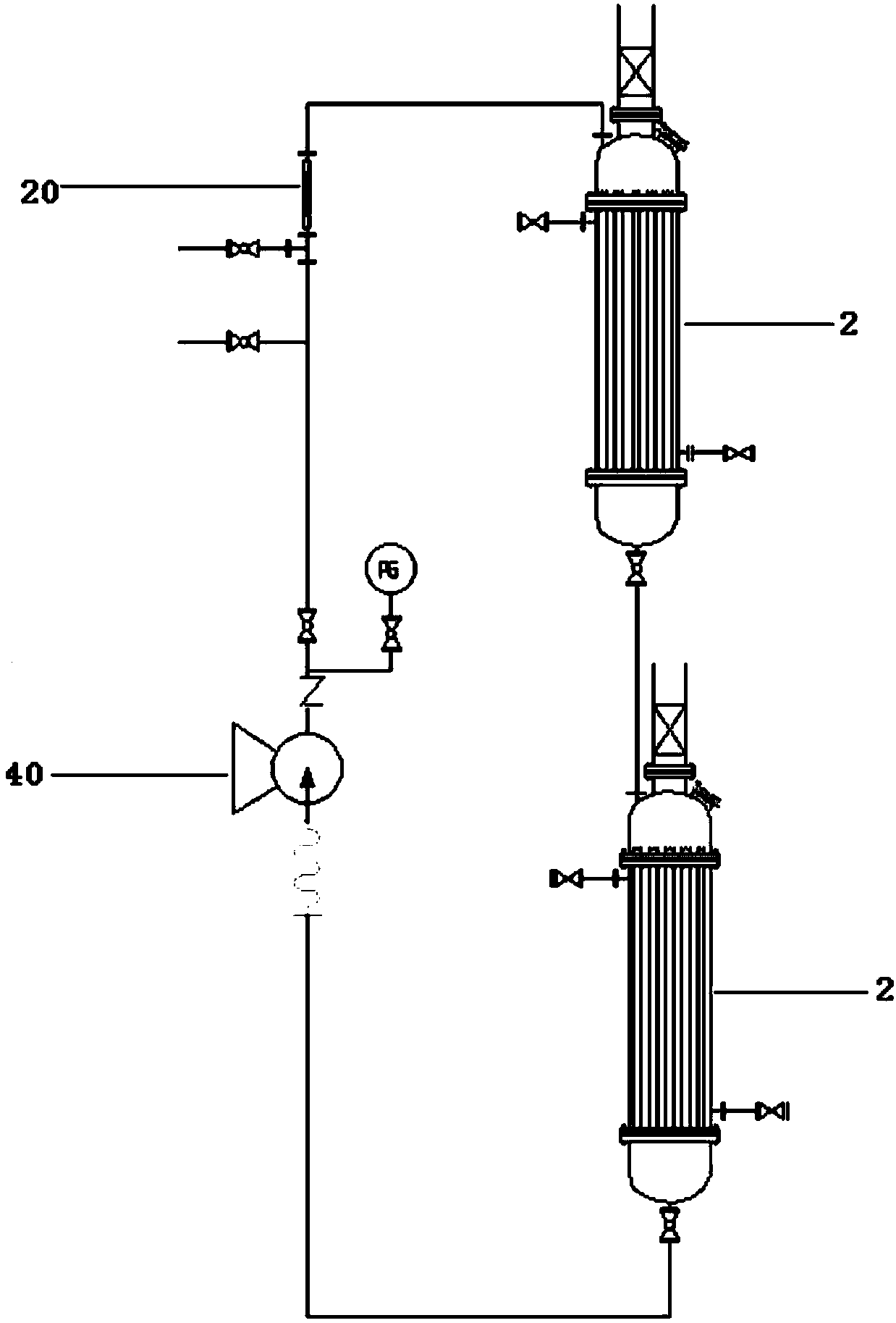

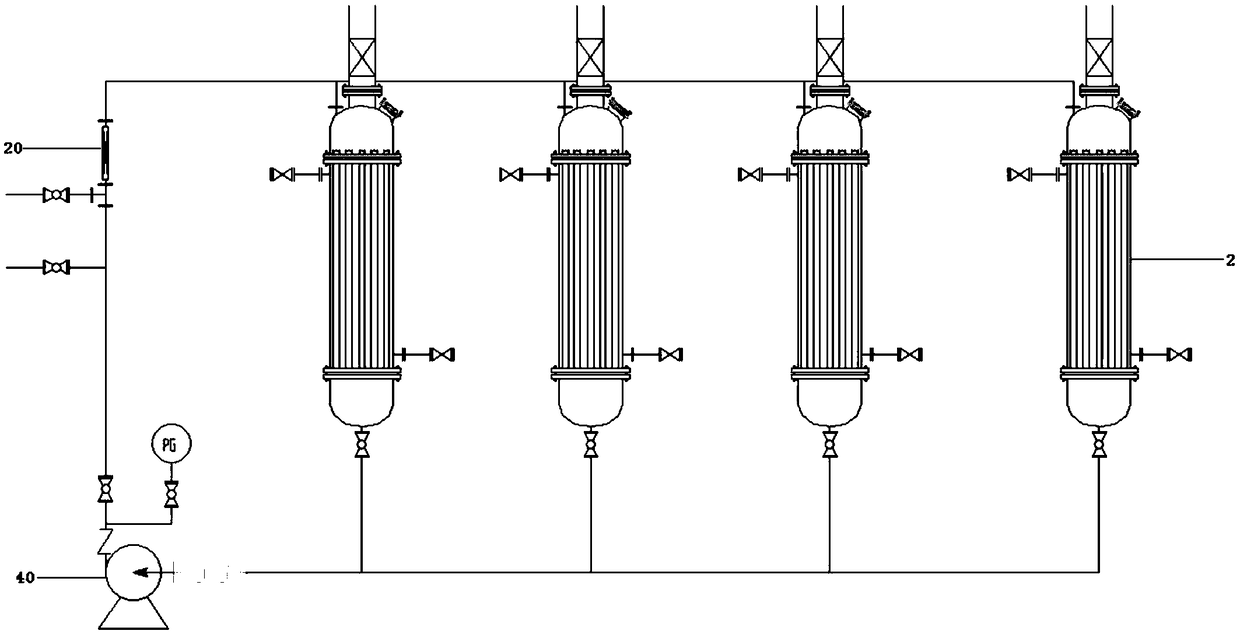

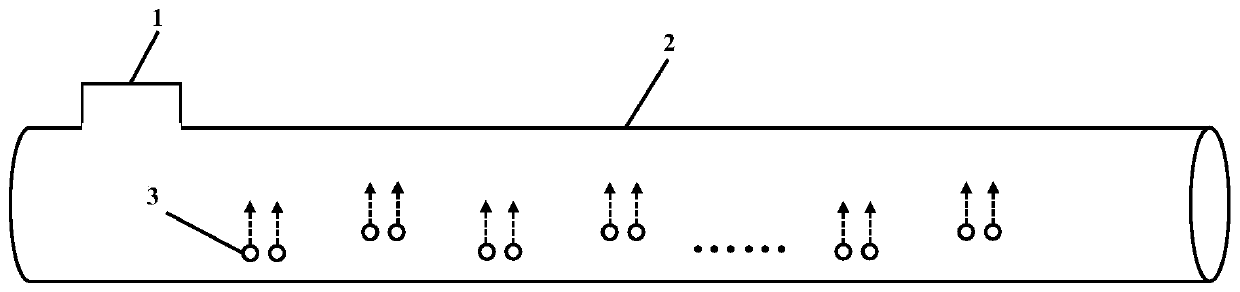

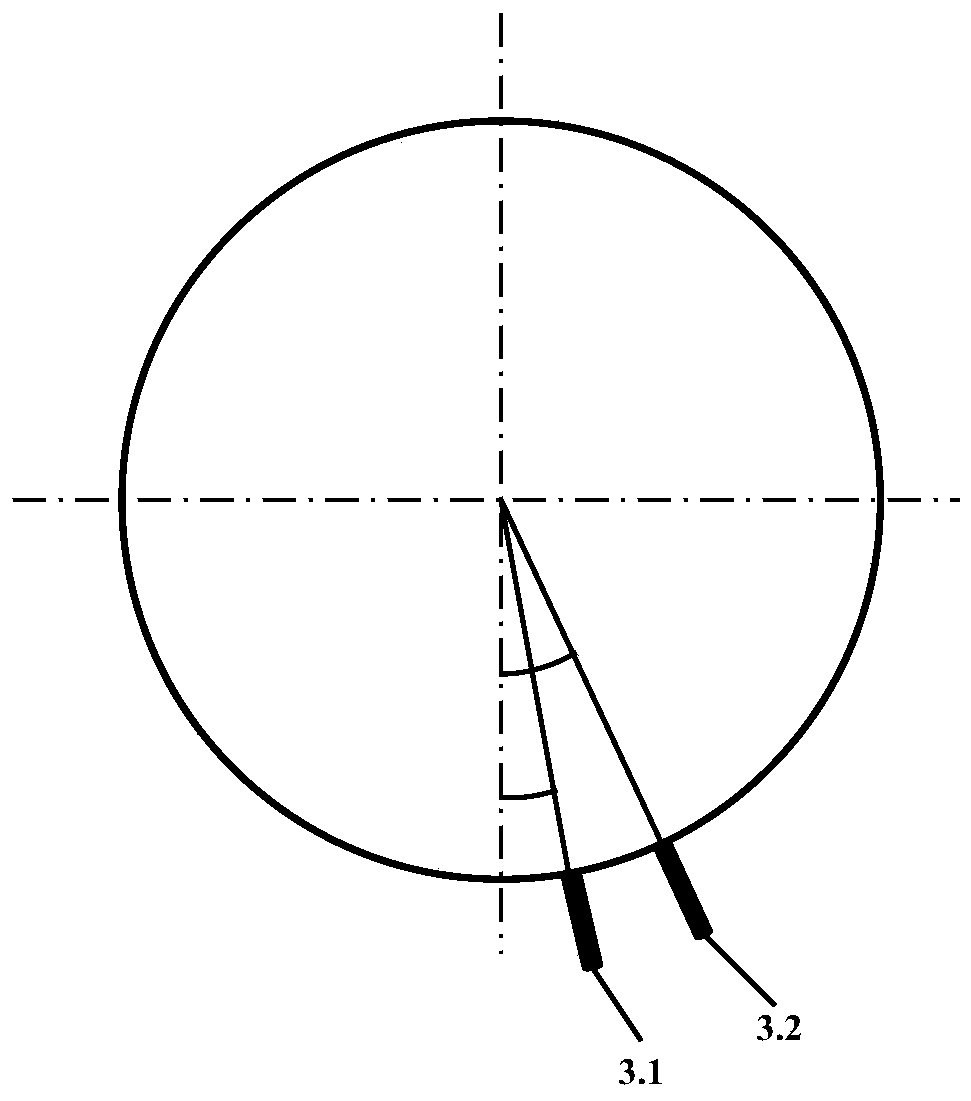

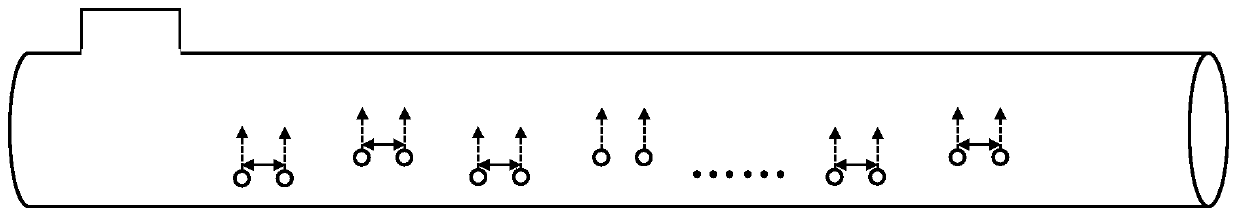

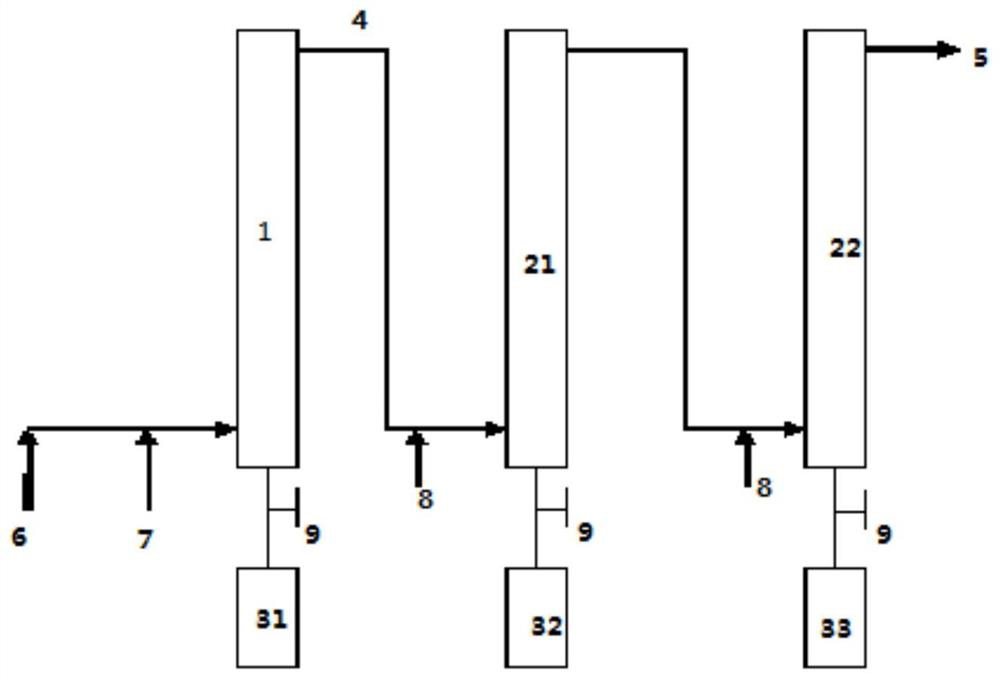

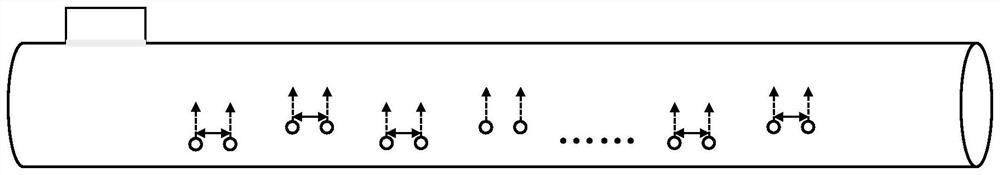

Self circulation array pipe reaction device with efficient mixer and reaction method using same

PendingCN109225114ALarge specific surface areaFast heat transferFlow mixersTransportation and packagingEngineeringCirculating pump

The invention relates to a self circulation array pipe reaction device with an efficient mixer and a reaction method using the same. The material mixing problem is solved through the arrangement of anefficient mixer and a circulation pump. The heat transfer problem and the reaction flux problem can be effectively solved in time through installing an array pipe reactor and controlling the circulation quantity. The reaction device provided by the invention has the advantages that the heat transfer effect is good; the material mixing is uniform; the continuous and automatic reaction can be realized. The reaction method using the reaction device provided by the invention has the advantages that the operation is simple; the reaction efficiency is high; the heat transfer effect is good; side reactions are few; the reaction flux is great.

Owner:葛沁怡

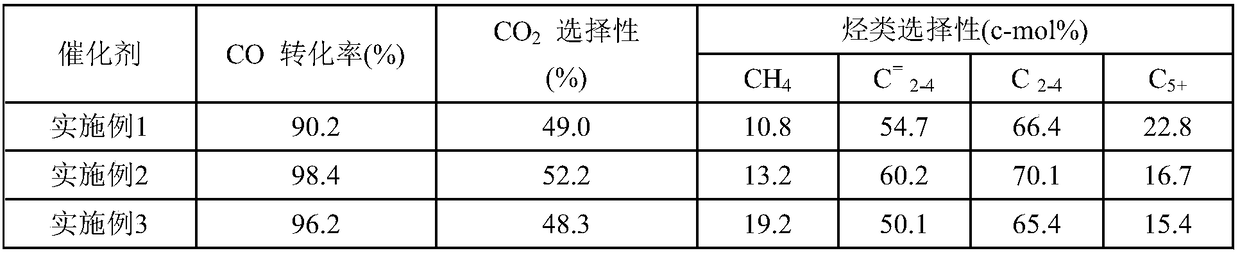

Foam carbon-based catalyst and preparation method and application thereof

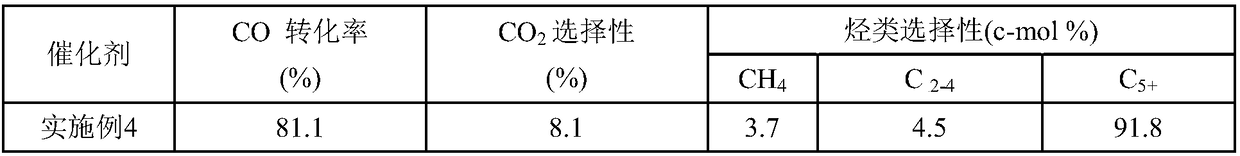

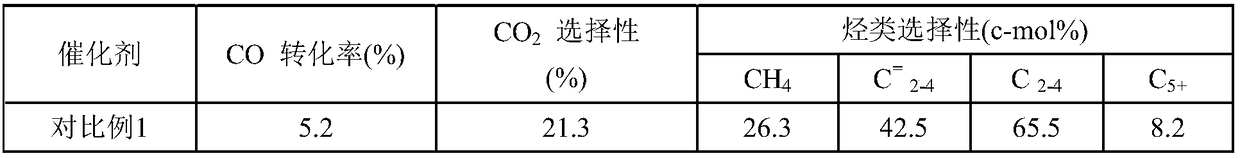

InactiveCN108607570ARegulatory responsivenessImprove diffusion abilityHydrocarbon from carbon oxidesOrganic compound preparationManganesePotassium

The invention discloses a foam carbon-based catalyst and relates to the field of catalysts. The foam carbon-based catalyst is prepared from a carrier which is porous foam carbon with a treated surfaceas well as active metals or active metals and additives combined on the surface of the carrier, wherein the active metals are selected from one or more of the following elements: iron, cobalt, nickel, copper, molybdenum, tungsten, ruthenium, platinum and rhodium, and the active metals exist in the form of a simple substance, an oxide or a carbide; and the additives are selected from one or more of the following elements: manganese, potassium, silver, calcium, magnesium, zirconium, aluminum, zinc, sodium and phosphorus, and the additives exist in the form of a simple substance or an oxide. Thefoamed carbon-based catalyst can adjust and control the selectivity of a reaction product when in use, and the catalytic reaction performance of the catalyst can be improved. The invention also discloses a preparation method and application of the catalyst.

Owner:BEIJING UNIV OF CHEM TECH

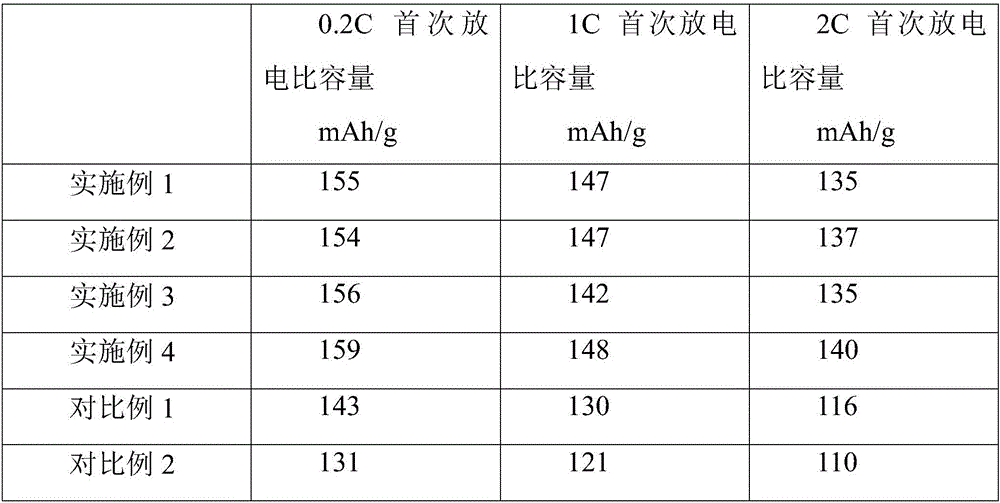

Preparation method of lithium iron phosphate cathode material

InactiveCN106848261AGood hole conductivityIncreased electronic conductivity and ion diffusion rateSecondary cellsPositive electrodesCarbon coatingDispersed media

The invention discloses a preparation method of a lithium iron phosphate cathode material. The preparation method comprises the following steps of (1), dispersing iron phosphate into a dispersing agent, so as to obtain dispersion liquid A of the iron phosphate; (2), dispersing a lithium carbonate and magnesium chloride doping agent into a dispersing agent, so as to obtain lithium source-magnesium source doping agent dispersion liquid B; (3), slowly adding the dispersion liquid A of the iron phosphate into the lithium source-magnesium source doping agent dispersion liquid B, enabling an obtained first mixture to react to make a coarse material of a lithium iron phosphate material; (4), grinding and uniformly mixing the coarse material of the lithium iron phosphate material and carbon-source glucose in a dispersing medium ethanol, drying an obtained second mixture, sintering the second mixture for 12h to 24h at a temperature of 700 to 750 DEG C in a protective atmosphere of a nitrogen gas, and naturally cooling the second mixture to a room temperature, so as to obtain the lithium iron phosphate cathode material. The non-in-situ carbon coating is adopted by the preparation method; meanwhile, the carbon coating is carried out in a sintering process; the increment of a crystal particle of the lithium iron phosphate material in a long-time high-temperature sintering process is limited; the electronic conductivity and the ion diffusion rate of the material are further improved; the lithium iron phosphate cathode material has better rate charging and discharging performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

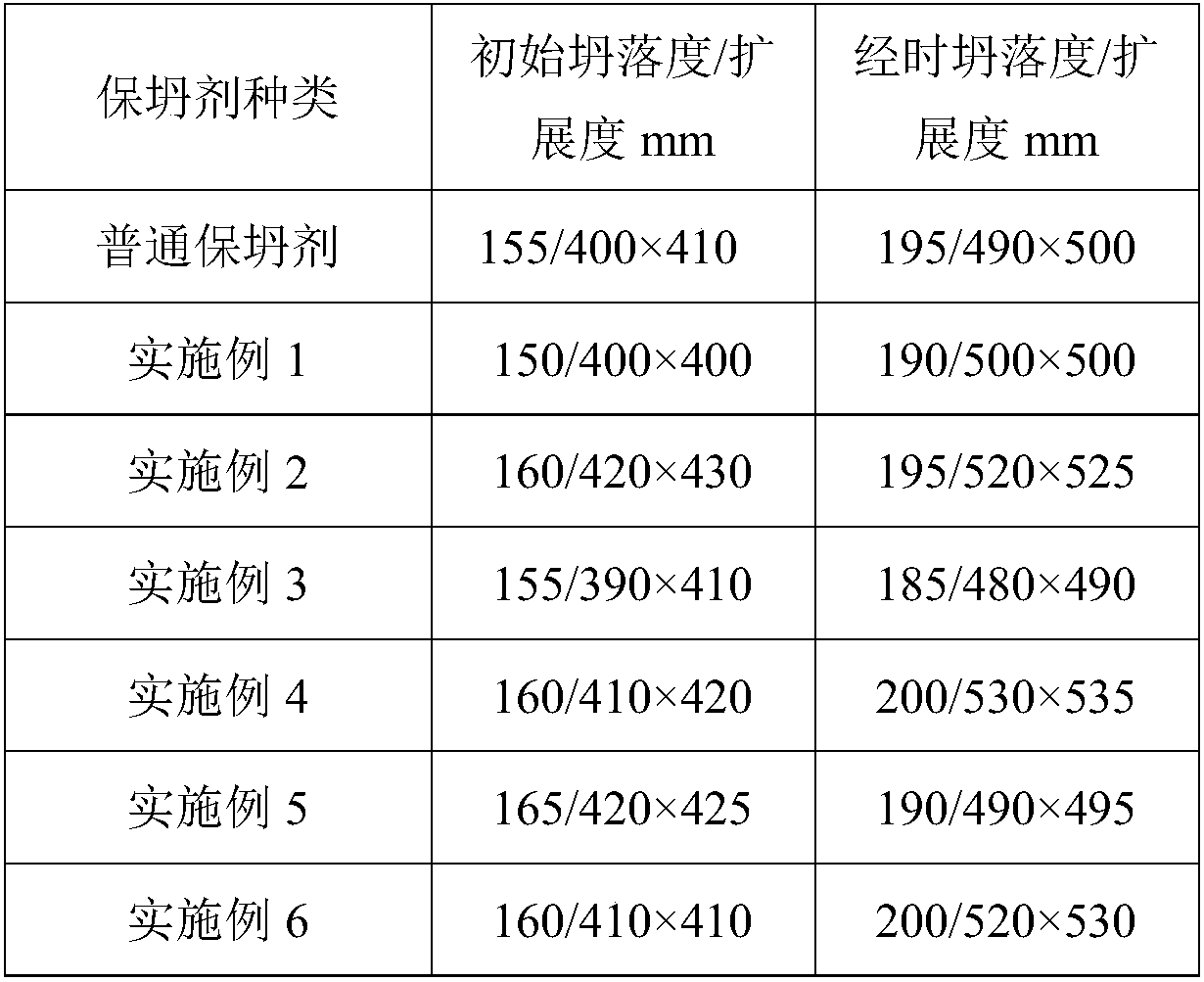

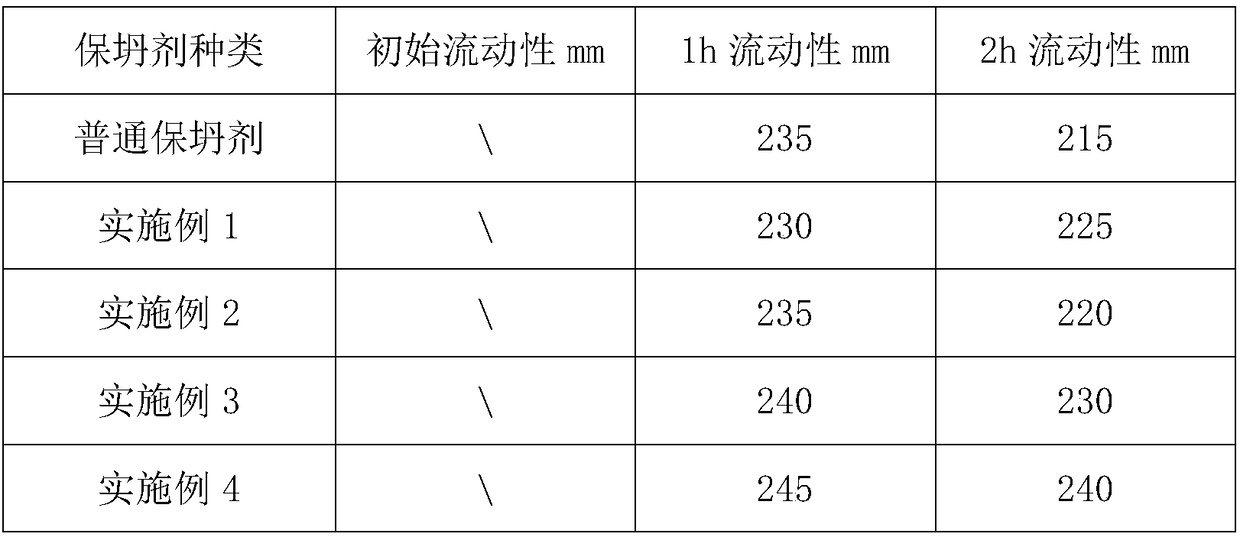

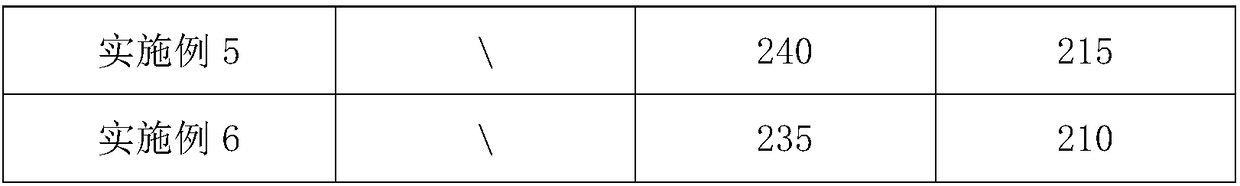

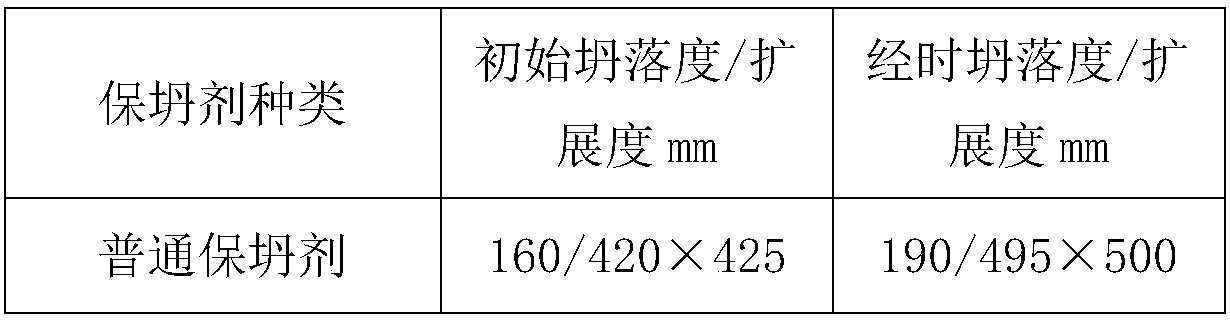

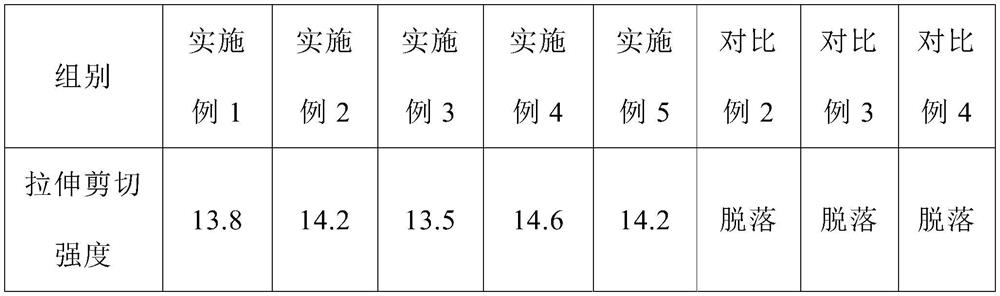

Preparation method of solid flake polycarboxylate slump retention agent for bulk polymerization

The invention provides a preparation method of a solid flake polycarboxylate slump retention agent for bulk polymerization. The method comprises the following steps: adding a certain amount of liquidpolyether macromonomer into a reaction kettle, stirring and heating; controlling the temperature to be 100-105 DEG C, and starting to add a certain amount of a solubilizer, a chain transfer agent, anorganic peroxy-initiator, an initial initiator and a penetrant; after 5 minutes, starting to dropwise add a small monomer solution, wherein the dropwise adding time of the small monomer solution is 0.5-2h, and the small monomer solution is prepared from a fluoro-functional monomer, alkyl acrylate and acrylic acid according to a certain proportion; after the body solution is added dropwise for 10min, firstly adding a certain amount of the organic peroxy-initiator into the kettle, then adding at a time every 10min, and adding for the last time until the time before the completion of the dropwiseaddition of the small monomer solution; after the dropwise addition is finished, heating up to 110-115 DEG C, maintaining the temperature to be constant, curing for 1-3h, then cooling, slicing and packaging to obtain the finished product. The final solid flake polycarboxylic acid slump retention agent prepared by the method is convenient to store, so that the transportation cost is greatly lowered.

Owner:HUBEI UNIV OF TECH

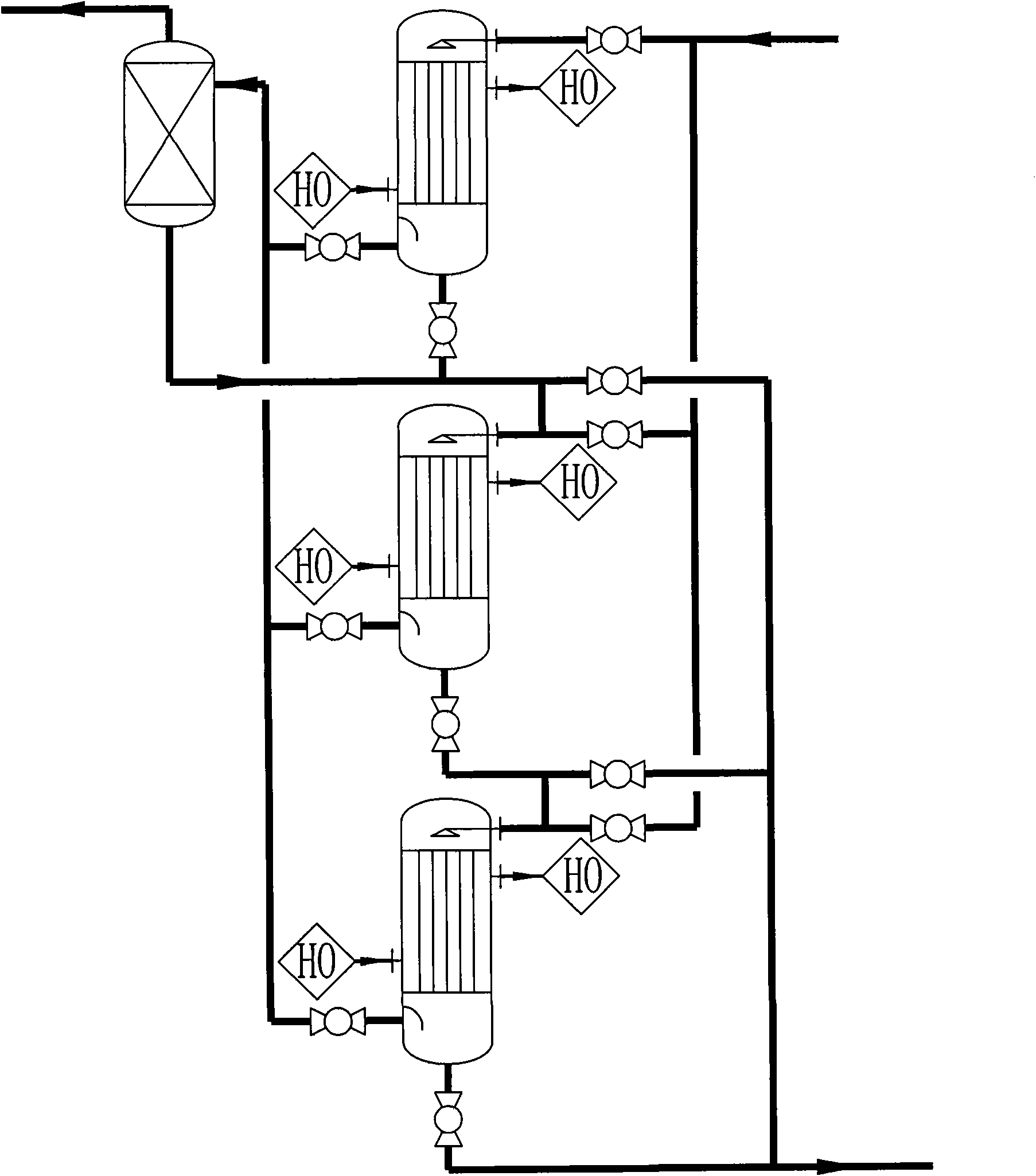

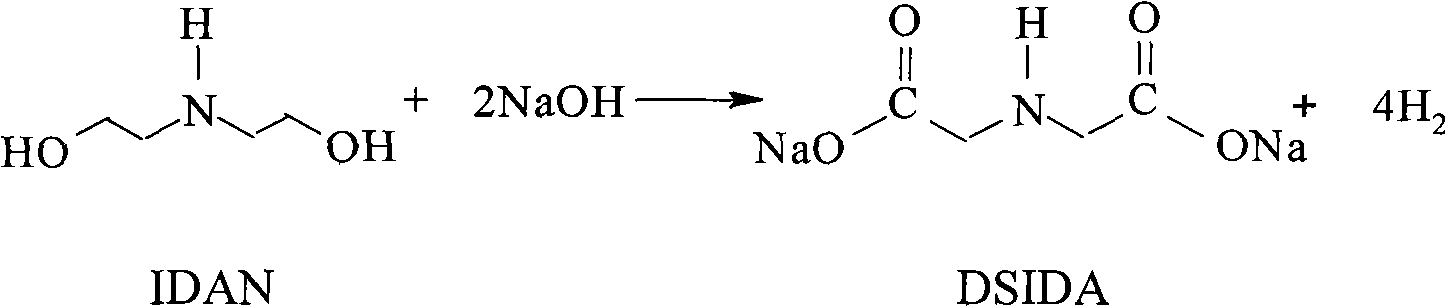

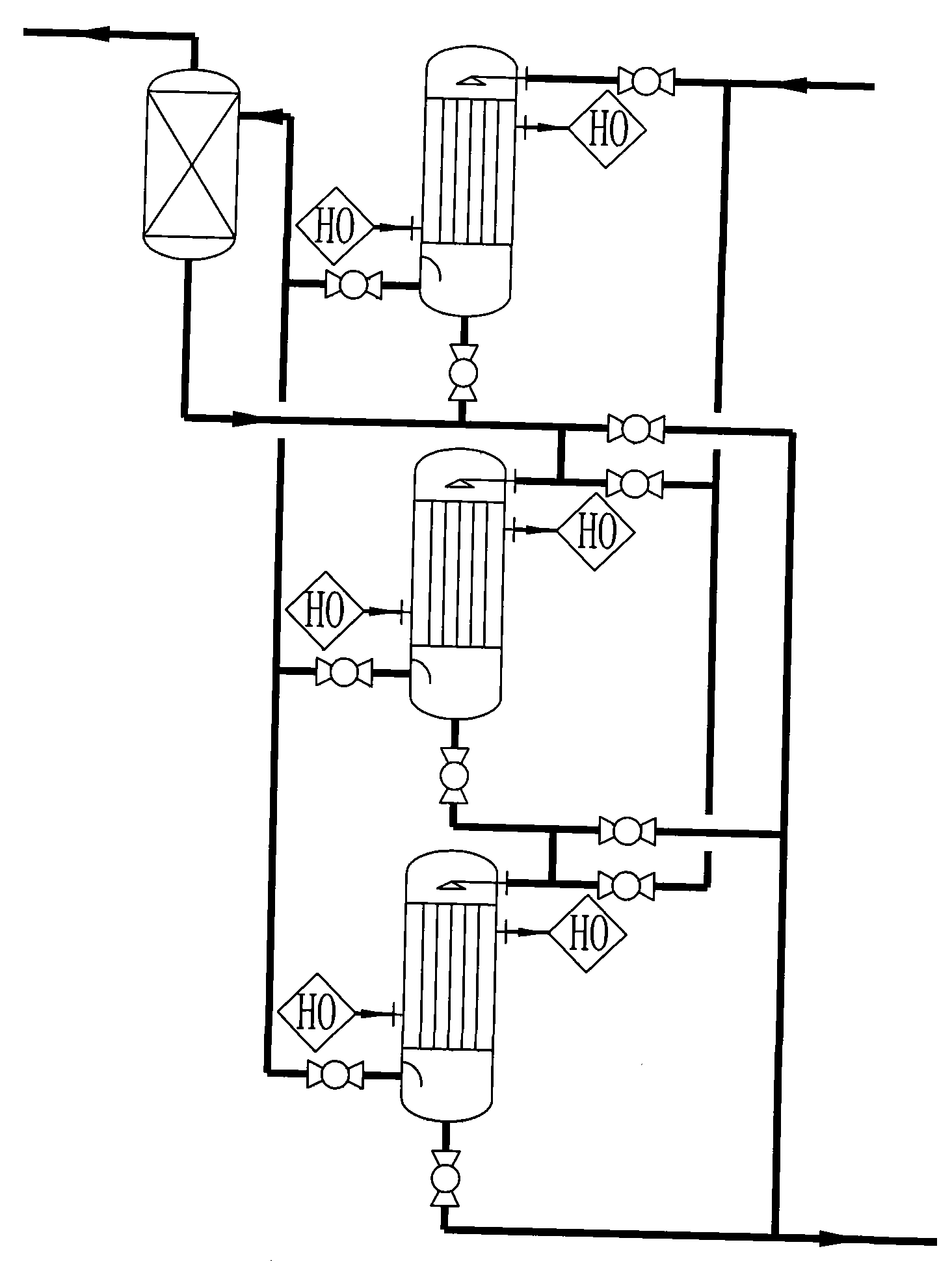

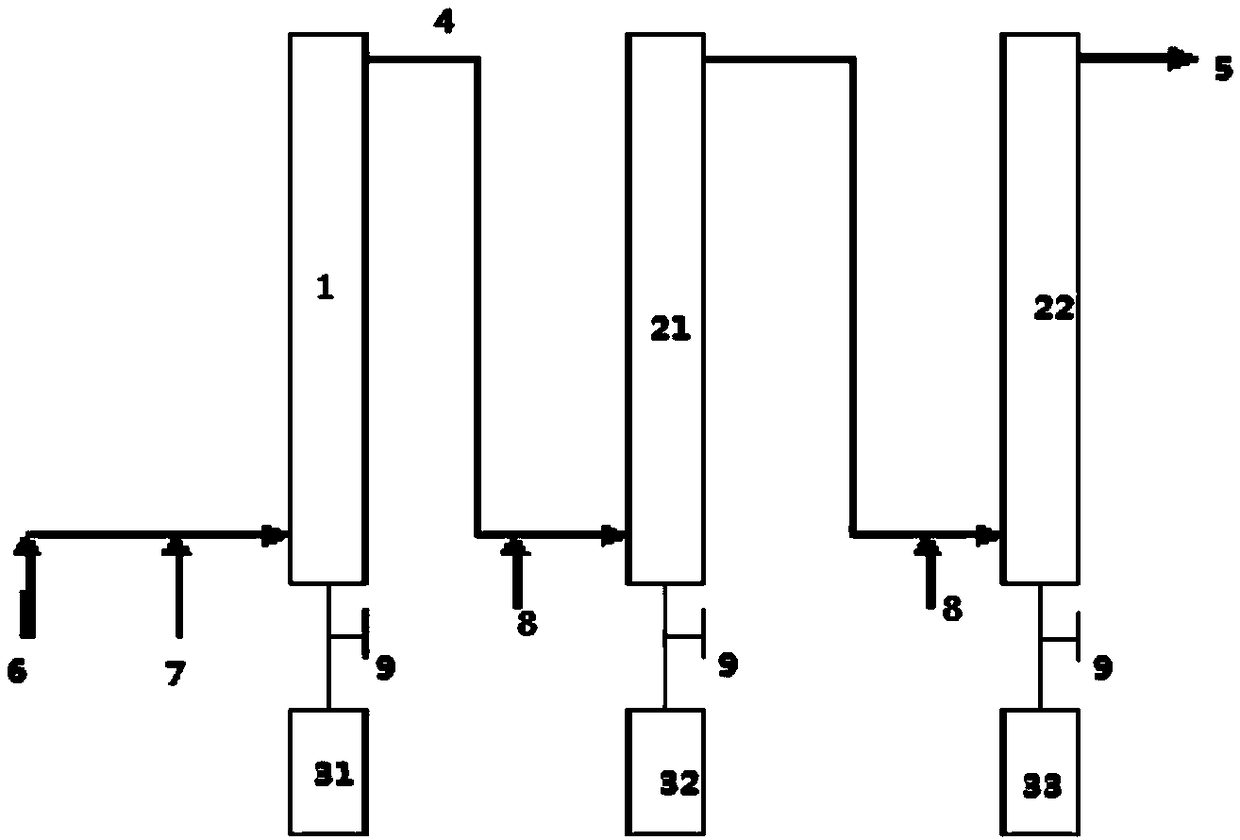

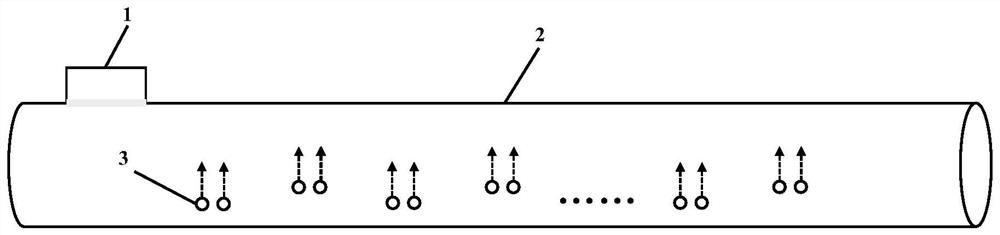

Synthesis as well as tail gas treatment technology and device of iminodiacetate

InactiveCN102050751AReduce typesEfficient removalOrganic compound preparationHydrogen separation using liquid contactDehydrogenationDiethanolamine

The invention relates to a synthesis technology and device of iminodiacetate. The technology uses diethanol amine as a main raw material and comprises the following steps: dissolving the diethanol amine, mixing with a caustic soda solution and deionized water evenly to prepare a feed liquid the mass concentration of which is 10-30%, and transferring the feed liquid into a multistage tubular reactor loaded with a solid catalyst through a metering pump to perform catalytic dehydrogenation reaction to obtain iminodiacetate; and treating the gas generated through catalytic dehydrogenation and the tail gas separated from the discharged liquid to recycle hydrogen. The device comprises the multistage tubular reactor which is designed on the basis of a kinetic model of isothermal constant-pressure reaction, wherein the multistage tubular reactor is formed by connecting 2 to 5 tubular reactors in series; each reactor is formed by a plurality of tubes; the same amount of catalyst is evenly filled in each tube; the upper part or lower part of each reactor is provided with a gas-liquid separator which is used for separating the gas generated through the dehydrogenation reaction from the discharged liquid; and the back of the gas-liquid separator is connected with a demister which is connected with a tail gas treatment device used for purification treatment through a regulating valve. The device provided by the invention has the characteristics that the technological operation is simple, the product yield is no less than 98%, the continuous production can be realized, the work efficiency can be increased, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

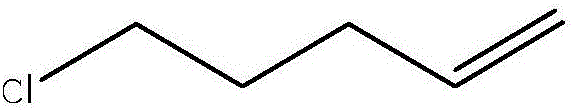

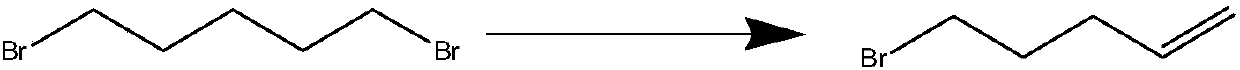

5-chloro-1-amylene synthesis method

ActiveCN105837396AInhibit side effectsAchieve low temperature reactionHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsAlcoholDistillation

The invention discloses a 5-chloro-1-amylene synthesis method .The method comprises the steps that excess 4-amylene-1-alcohol and thionyl chloride are used as reaction raw materials, pyridine is used as a solvent, chlorination is catalyzed through a catalyst at low temperature, and5-chloro-1-amylene is obtained with high yield .The purpose of avoiding side reactions is achieved by changing technological conditions, and finally high selectivity and the high conversation rate of the reaction is achieved; after reaction liquid is processed, the product with the content of 98% or above can be obtained through a simple distillation means .By adding bismuth trioxide as the catalyst for catalyzing the reaction, low-temperature reaction is achieved, and the reaction conversion rate can reach 95.22% to the highest degree .

Owner:西安方昊化工有限公司

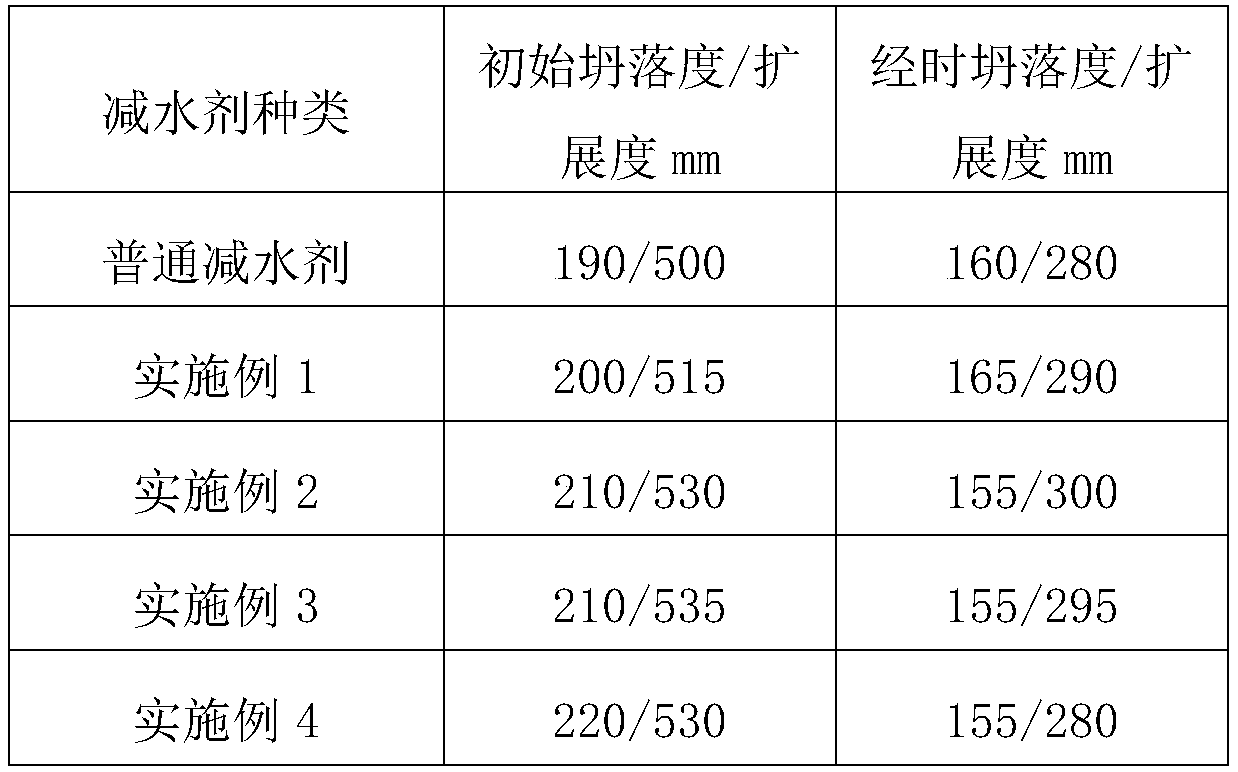

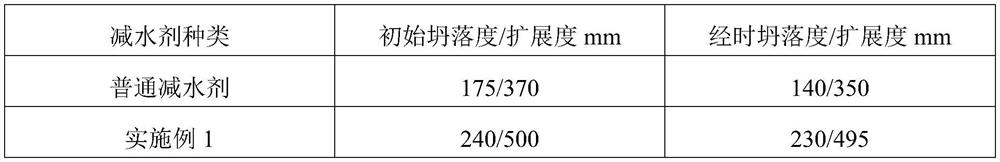

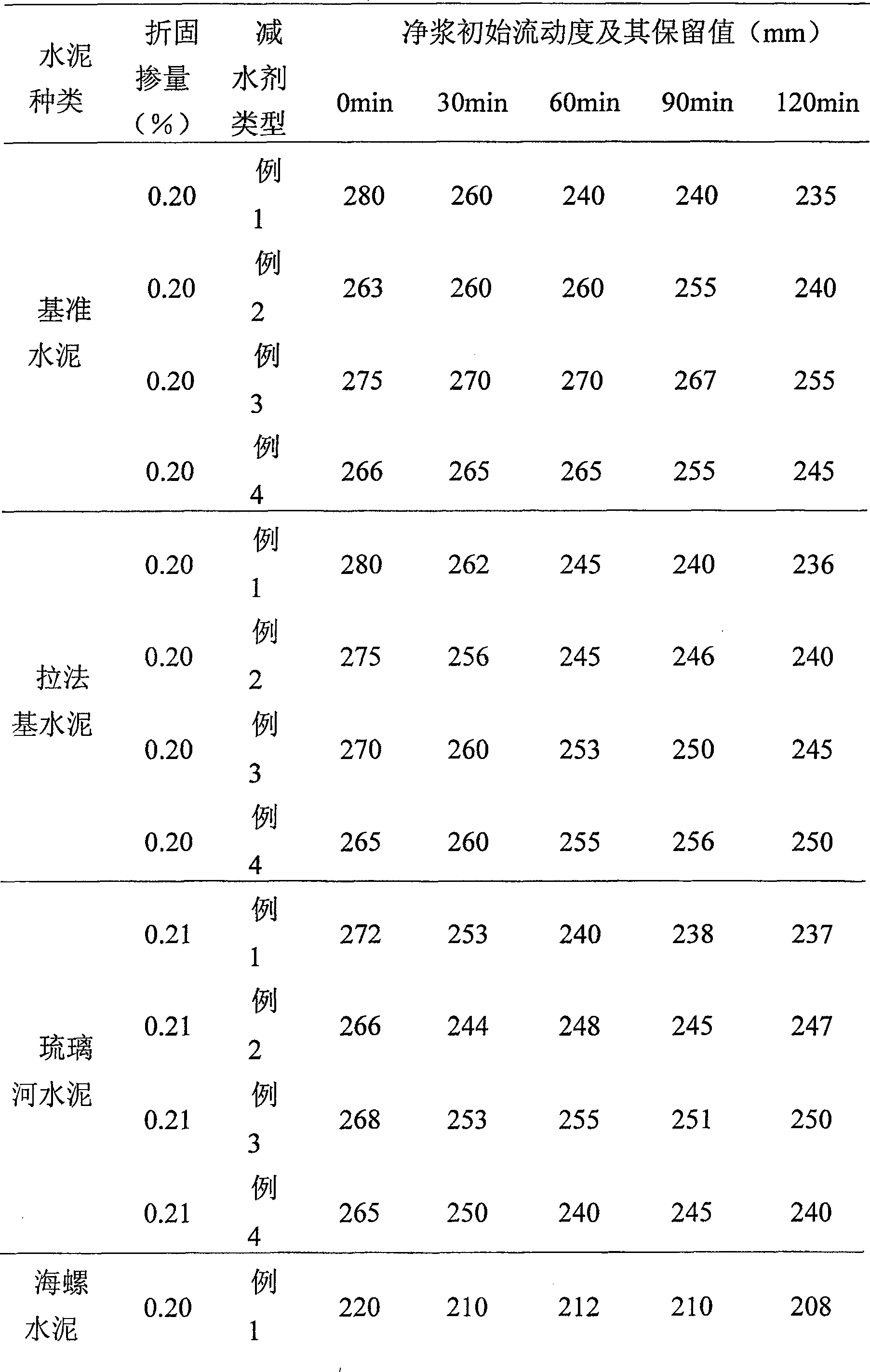

Preparation method of high-adaptability high-solid-content polycarboxylic acid slump retaining agent

The invention provides a preparation method of high-adaptability high-solid-content polycarboxylic acid slump retaining agent. The preparation method comprises the following steps: (1) adding polyether macro monomers and water in a given ratio into a reaction kettle, stirring, heating, and dissolving; (2) controlling the temperature at 70 to 75 DEG C, adding a given amount of solubilizer, chain transferring agent and organic peroxide initiator; (3) 5 minutes later, dropwise adding a solution B, 10 minutes later dropwise adding a solution A, wherein the addition time of the solution A is a hour, the addition time of the solution B is (a+0.5) hours, the solution A is prepared from acrylic alkyl ester, acrylic acid and water in a given ratio, and the solution B is prepared from an azo initiator, an alcohol organic solvent and water; and (4) after the dropwise addition is completed, raising the temperature to 95 to 98 DE C, keeping the temperature constant, curing for b hours, then cooling, slicing, and packaging, thus obtaining the high-adaptability high-solid-content polycarboxylic acid slump retaining agent with the solid content of 92 to 98 percent. The product obtained by the method provided by the invention has the characteristics of high solid content, good adaptability, good slump retaining performance and the like and is suitable for industrialized production.

Owner:HUBEI UNIV OF TECH

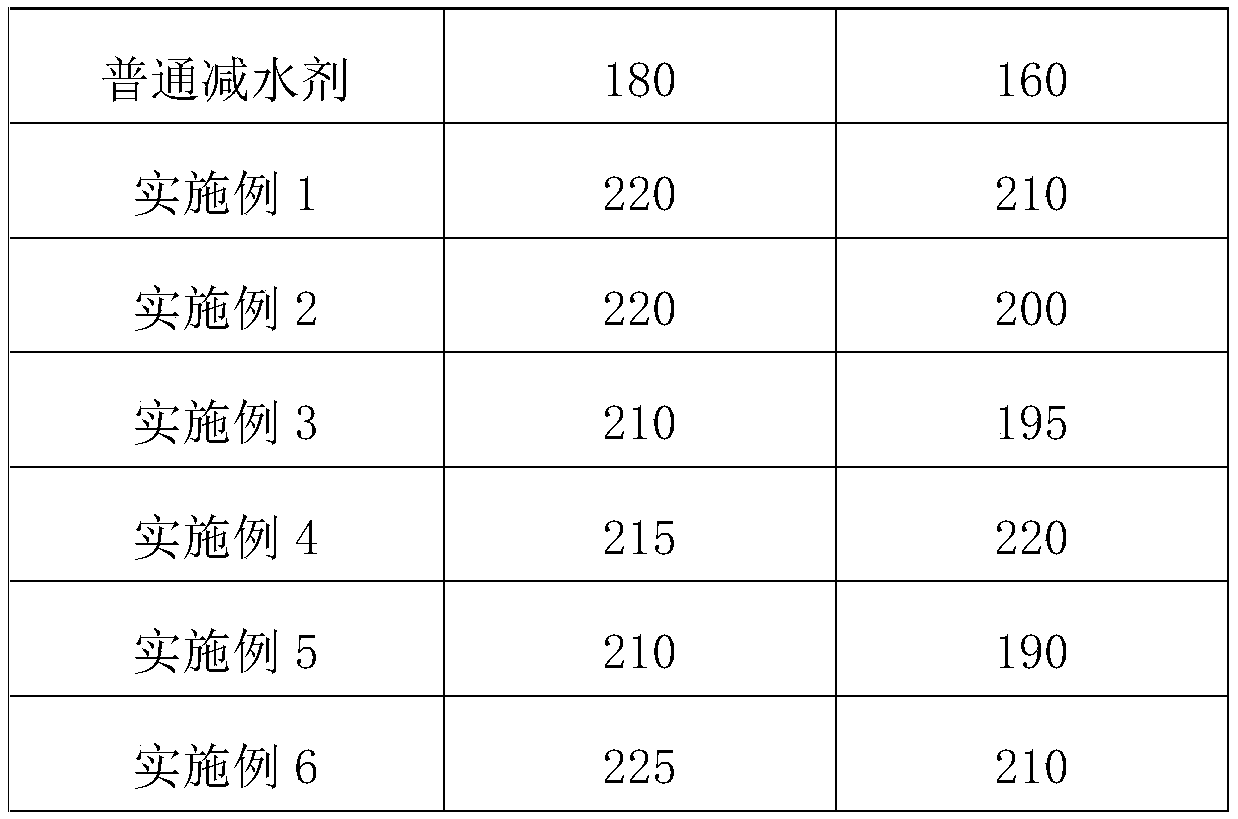

Preparation method of polycarboxylate water reducer with high adaptability and high solid content

The invention provides a preparation method of a polycarboxylate water reducer with high adaptability and high solid content. The preparation method comprises the following steps: 1) adding a polyether macromonomer and water to a reactor according to a certain proportion, stirring and heating till being dissolved; 2) controlling the temperature to be 70 to 75 DEG C, starting to add a certain amount of an organic peroxygen initiator, a solubilizer and a chain transfer agent; 3) after 5min, starting to add a solution B, and after 10min, starting to add a solution A, wherein the dropping time ofthe solution A is a hours, and the dropping time of the solution B is a+0.5 hours; the solution A comprises acrylic acid and water in a certain proportion, and the solution B comprises an azo initiator and an alcohol organic solvent; 4) after dropwise adding, rising the temperature to 95 to 98 DEG C, keeping the temperature constant, curing for b hours, later cooling, slicing and packing to obtainthe polycarboxylate water reducer with the high adaptability and high solid content. The product prepared by the invention has the characteristics of high solid content, good adaptability, high water-reducing rate, good slump retention ability and the like and is suitable for industrial production.

Owner:HUBEI UNIV OF TECH

Method and system for preparing biodiesel by tubular-temperature variation continuous method

ActiveCN108929787AHigh reaction conversion and product yieldOvercome the defect of short running cycleFatty acid esterificationBiofuelsGlycerolEngineering

The invention relates to the field of preparation of biodiesel, and discloses a method and system for preparing biodiesel by a tubular-temperature variation continuous method. The method comprises thefollowing steps: directly introducing raw materials containing grease and alcohols into a vertical tubular reactor from the lower part of the vertical tubular reactor for carrying out a reaction, andenabling the obtained product to flow out from the upper part of the vertical tubular reactor to obtain a first material; introducing the first material into one or at least two vertical tubular reactors which are connected in series for carrying out a reaction to obtain a second material from the upper part of the last vertical tubular reactor; and carrying out monohydric alcohol removal treatment on the second material and carrying out separation treatment of an ester phase and glycerol. The method for preparing the biodiesel by the tubular-temperature variation continuous method can be used to avoid the defect that when preheating is carried out in a preheater, the device cannot be stably operated for a long period due to the accumulation of sediments in the high-pressure heater.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of barrier intercalation anti-mud type polycarboxylate water reducer

The invention provides a preparation method of a barrier intercalation anti-mud type polycarboxylate water reducer. The method comprises the following steps: (1) adding a polyether macromonomer, a hydroxyl functional monomer, a phosphate functional monomer and water into a reaction kettle according to a certain proportion, stirring and heating until the materials are dissolved; (2) controlling thetemperature to be 55-60 DEG C, and starting to add a certain amount of a penetrant and a chain transfer agent; (3) after the addition of the penetrant and the chain transfer agent is finished for 5 minutes, starting to dropwise add a solution A and a solution B at the same time, starting to dropwise add a solution C within 10 minutes after the start of the dropwise addition of the solution A andthe solution B, wherein the dropwise addition time of the solution C is a hours, the dropwise addition time of the solution A and the solution B is a+0.5 hours, the solution A is prepared from an initiator, alcohol organic solvents and water, the solution B is prepared from hydrogen peroxide and water, and the solution C is prepared from carboxylate, acrylic acid and water; (4) after the end of the dropwise addition, heating up to 70-75 DEG C, maintaining the temperature to be constant, curing for b hours, adding a neutralizing agent when the temperature of the reaction solution is lower than30 DEG C, and replenishing water to obtain the barrier intercalation anti-mud type polycarboxylate water reducer.

Owner:HUBEI UNIV OF TECH

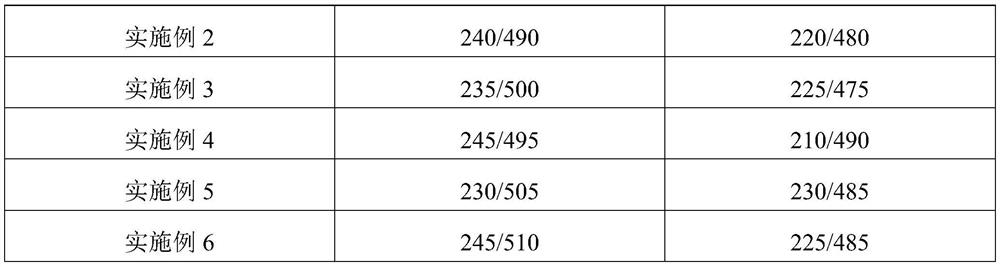

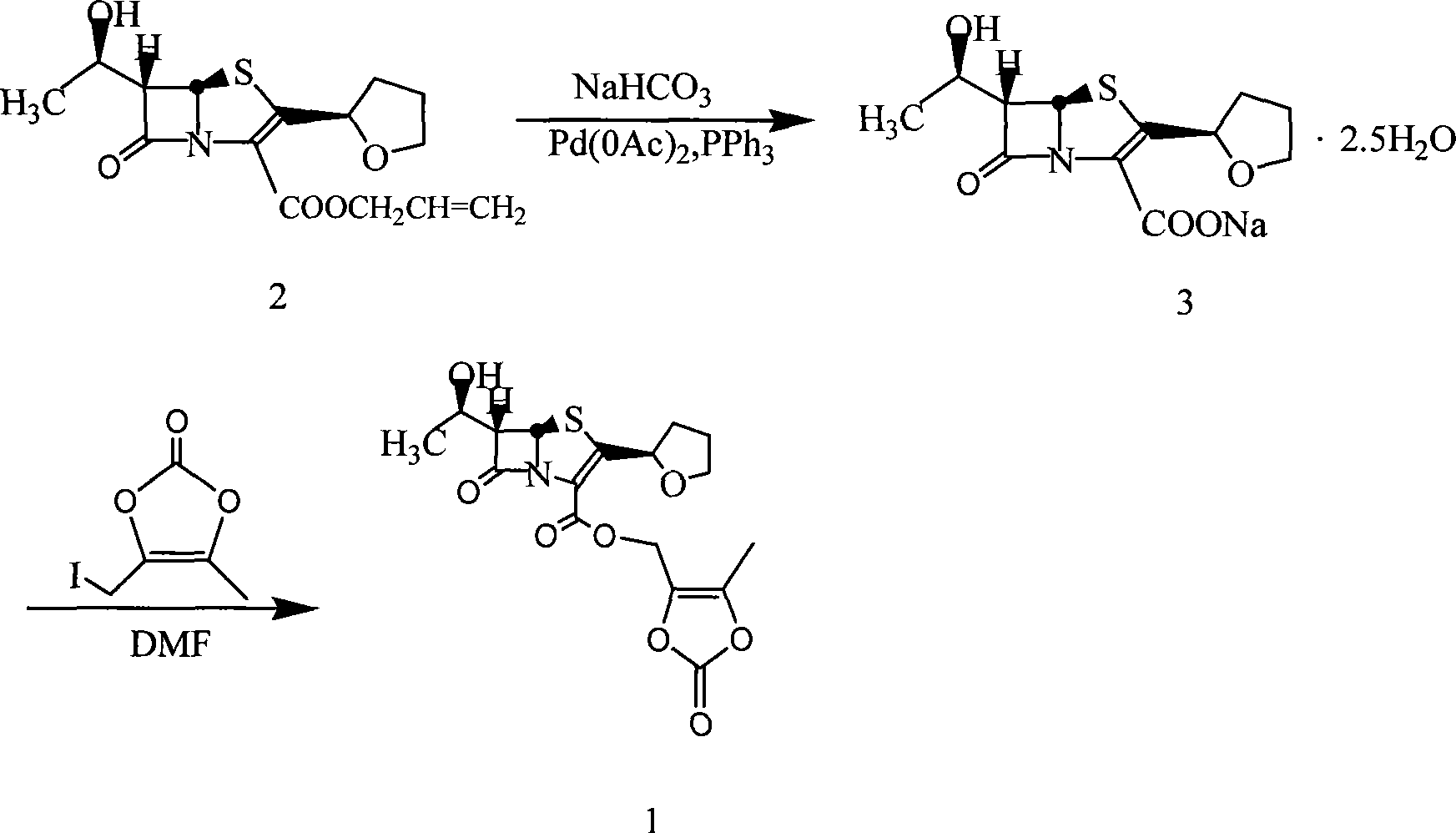

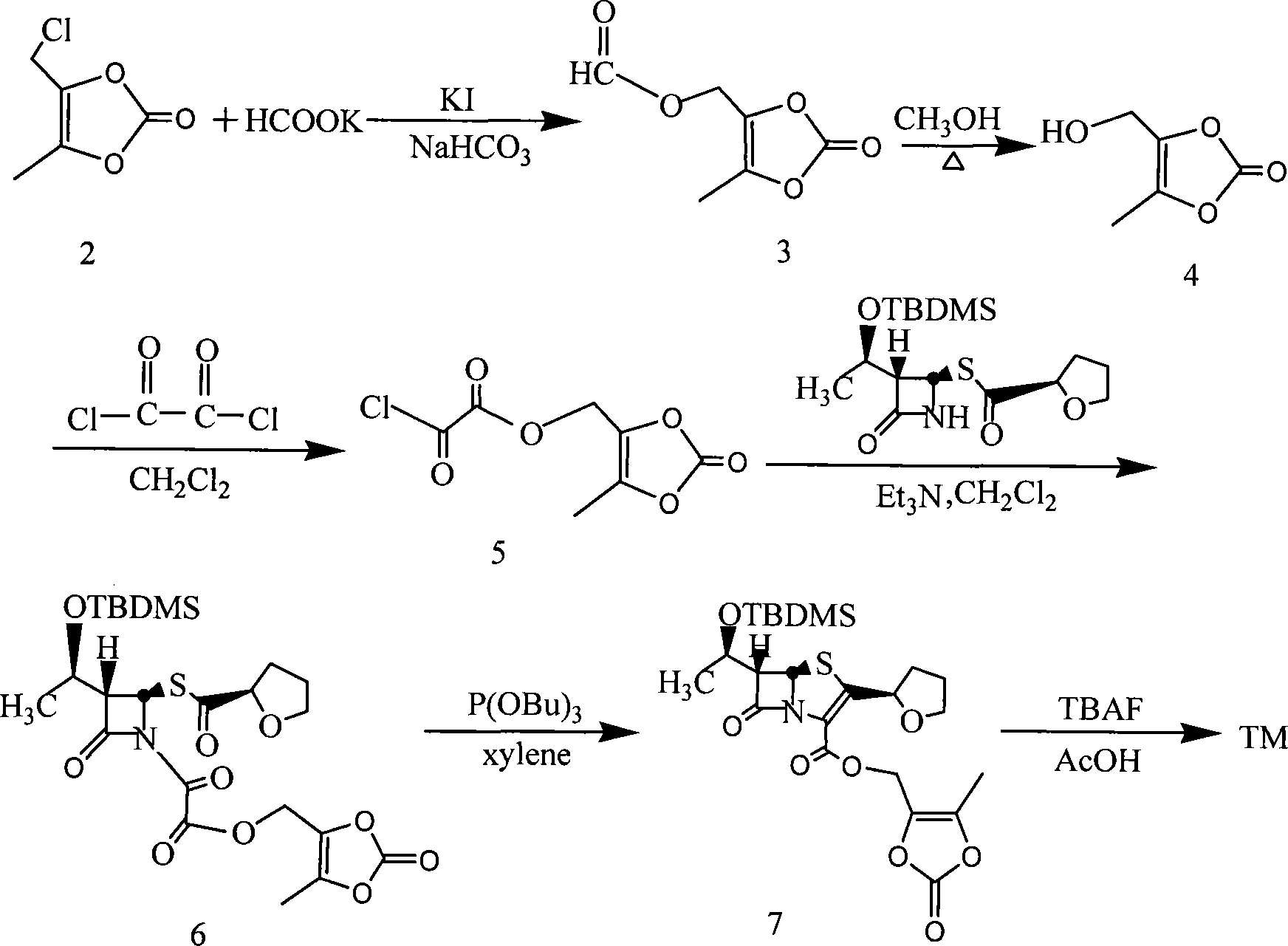

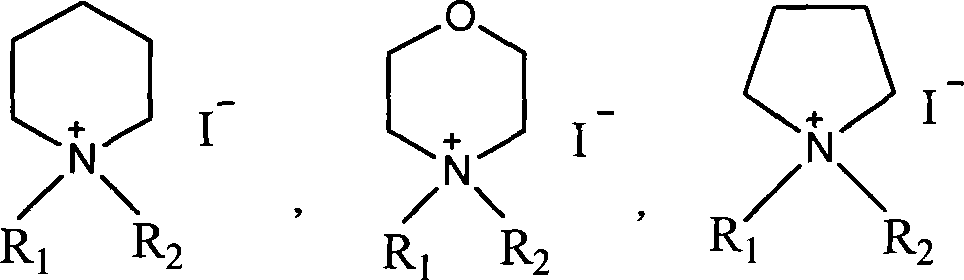

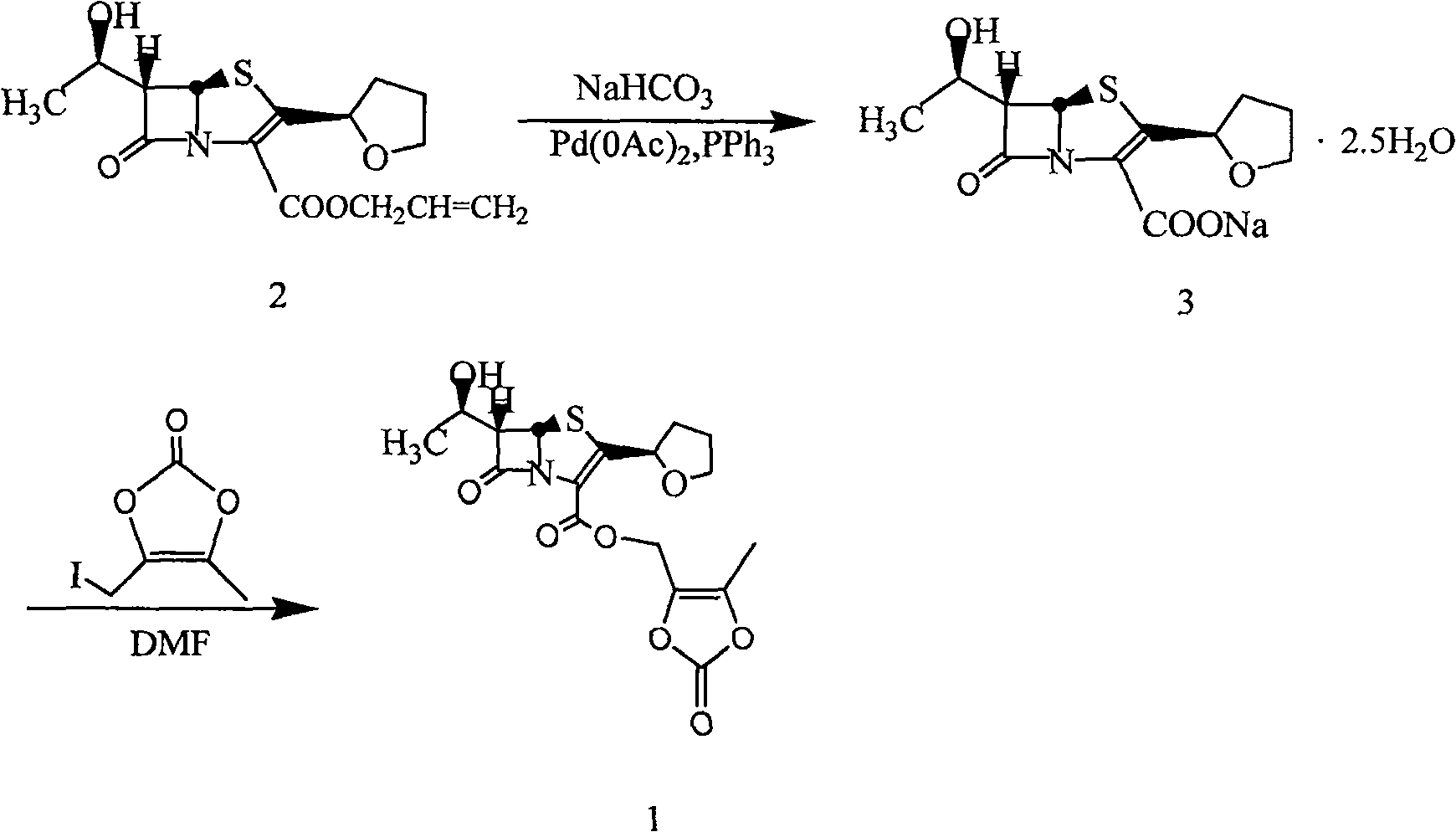

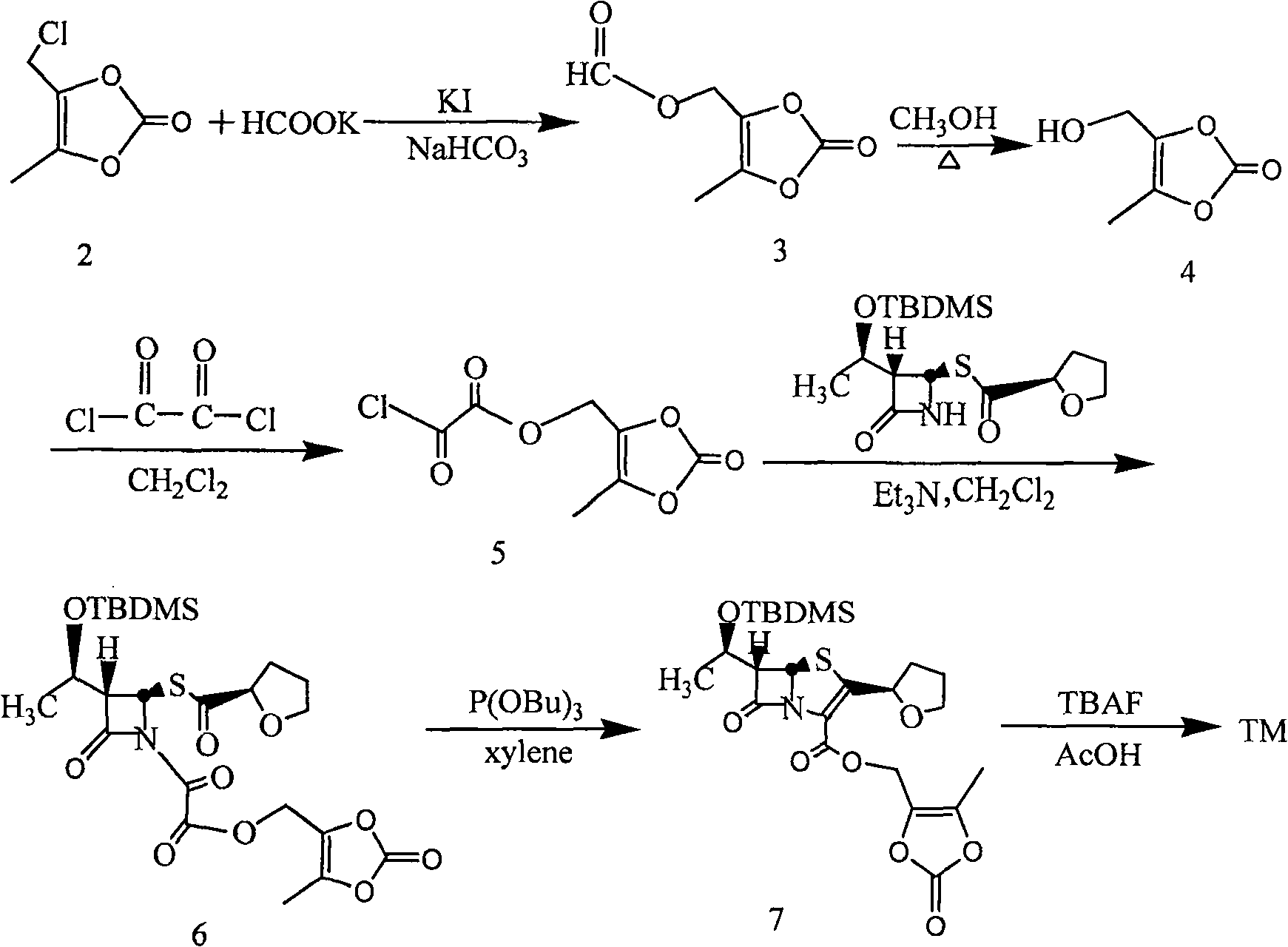

Method for preparing faropenem daloxate

ActiveCN101235044AEasy to operateLow costOrganic chemistryAntiinfectivesCyclopenteneChemical synthesis

The invention relates to a preparation method of faropenem medoxomil, belonging to chemical synthesis technical field, which is characterized in that faropenem and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in alkali condition and solvent A, via phase transfer catalyst and reaction promoter containing iodine are synthesized to obtain faropenem medoxomil, or the inorganic salt of faropenem medoxomil and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in solvent B, via phase transfer catalyst and reaction promoter containing iodine are synthesized to obtain faropenem medoxomil. The method has simple operation, mild reaction and saved cost, while the synthesized faropenem medoxomil has high yield and purity.

Owner:NANJING HUAWE MEDICINE TECH DEV +1

Preparation technique of dibutyl tin diacetate

InactiveCN104497036AGuaranteed overdoseGuaranteed responseTin organic compoundsAcetic acidBoiling point

The invention belongs to the technical field of catalyst preparation, and particularly relates to a preparation technique of dibutyl tin diacetate. The technique comprises the following steps: (1) weighing excessive glacial acetic acid for reaction, and adding into reaction kettle; (2) starting a stirring device, and adding dibutyl tin oxide while stirring; (3) heating to 60-80 DEG C, and keeping the temperature to react for 1-2 hours until the dibutyl tin oxide is completely dissolved; (4) vacuumizing, heating to 105 DEG C, stopping heating, and keeping the temperature for 20-30 minutes; (5) continuing heating to 110 DEG C, keeping the temperature, and vacuumizing for 2-3.5 hours until no low-boiling-point substance is distilled off; and (6) discharging, and weighing to obtain the required dibutyl tin diacetate. The technique has the advantages of complete reaction, low production cost and good product quality.

Owner:CHANGSHA LUOSI TECH

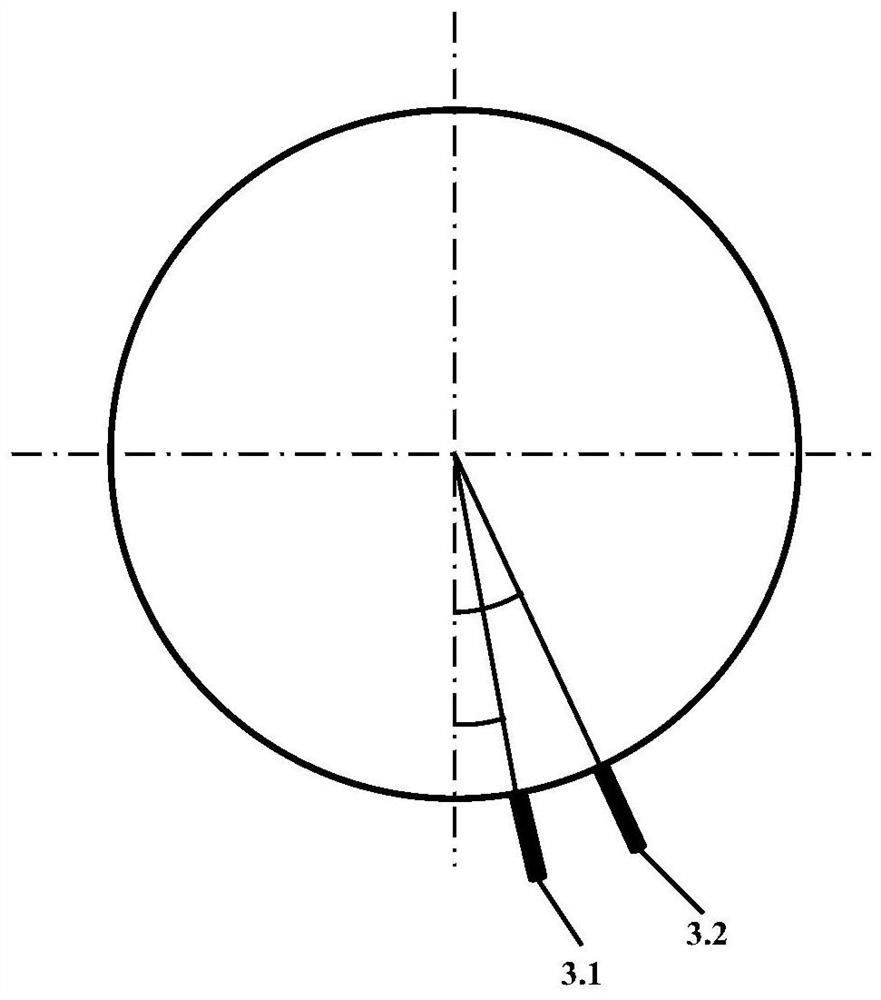

Method for reinforcing smelting effect of bottom blowing smelting furnace and avoiding melt splashing

ActiveCN110885933AStir wellPromote complete reactionRotary drum furnacesCrucible furnacesEngineeringMaterials science

The invention discloses a method for reinforcing a smelting effect of a bottom blowing smelting furnace and avoiding melt splashing, and belongs to the technical field of bottom blowing smelting furnaces. The method comprises the steps of cross flow blowing and peak staggering blowing which are used in a combined manner. The cross flow blowing ensures that under the condition that the blowing strength of each set of adjacent blowing guns is the same, the positions of the blowing guns are changed, states of two adjacent strands of blowing airflows generate the difference, and the aims of relieving airflow overlaying, restraining splashing and reinforcing blowing can be achieved; and peak staggering blowing ensures that under the condition that the positions of each set of adjacent blowing guns are same, the blowing strength is changed, the difference is generated between states of two adjacent strands of blowing airflows, and the aims of relieving airflow overlaying, restraining splashing and reinforcing blowing can be achieved. Through the method, melt stirring in the bottom blowing furnace is more uniform, furnace charge is promoted to have a complete reaction, it is prevented that furnace slag generated by bottom blowing smelting includes metal and a raw material, the melt surface layer splashing is avoided, the too concentrated washing stress borne by the wall face close tothe blowing guns can be weakened, and the capacity of the bottom blowing smelting furnace can be improved.

Owner:UNIV OF SCI & TECH BEIJING

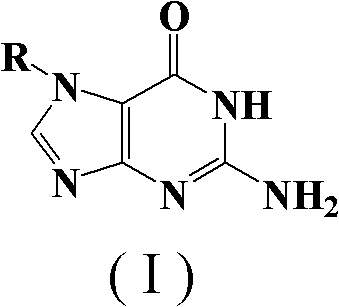

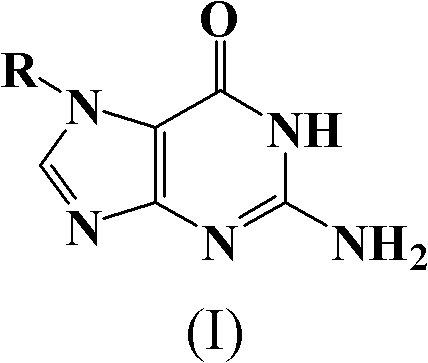

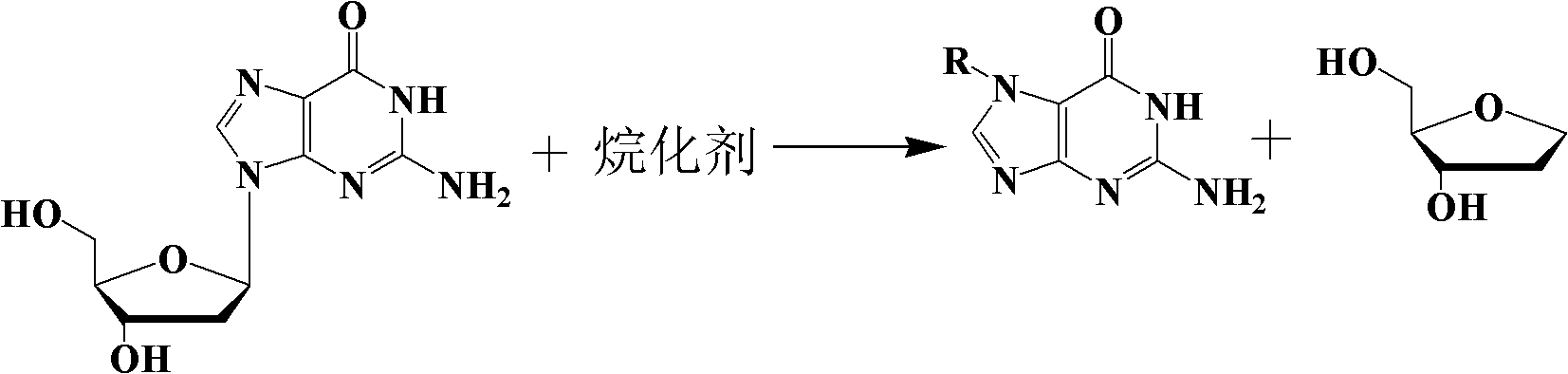

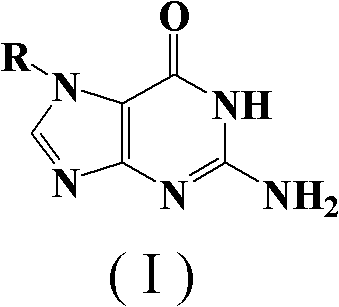

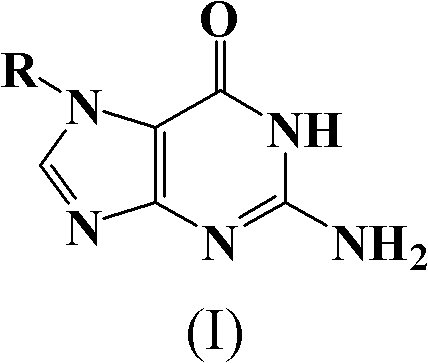

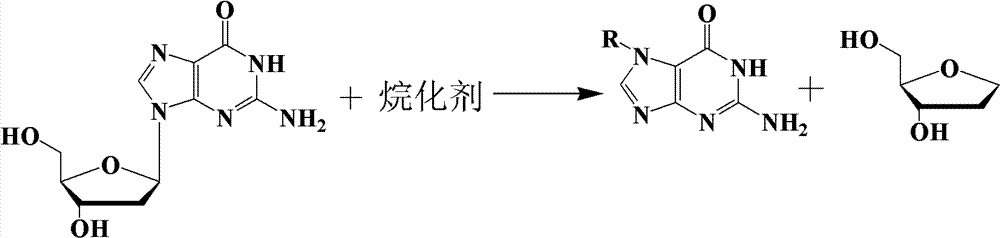

The preparation method of n7-guanine alkylate

InactiveCN102276610AImprove solubilityPromote complete reactionOrganic chemistryDistillationSilica gel

The invention relates to a method for preparing an N7-guanine alkylate. The method comprises the following steps of: reacting 2'-deoxyguanosine serving as a raw material and iodoethane, ethylene oxide, 1-bromo-2-ethyl chloride, 3-allyl bromide or 1,2-dibromoethane serving as an alkylate in a dimethyl sulfoxide, glacial acetic acid or dimethyl acetamide solution at a temperature of 15-50 DEG C for0.5-96 hours; performing reduced pressure distillation after the reaction is finished; separating and purifying a rough product through silica gel column chromatography; and eluting with an eluent comprising acetic ether and petroleum ether in a volume ratio of (10-20):1 and an eluent comprising acetic ether and absolute methanol in the volume ratio of (10-20) :1 respectively to obtain the N7-guanine alkylate. The method has the advantages of mild reaction conditions, simple separation and purification process, high product yield, less environmental pollution and the like and contributes to mass production of the N7-guanine alkylate.

Owner:BEIJING UNIV OF TECH

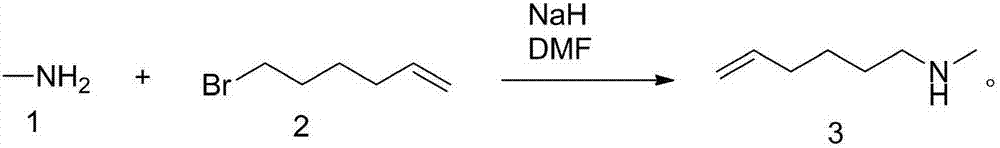

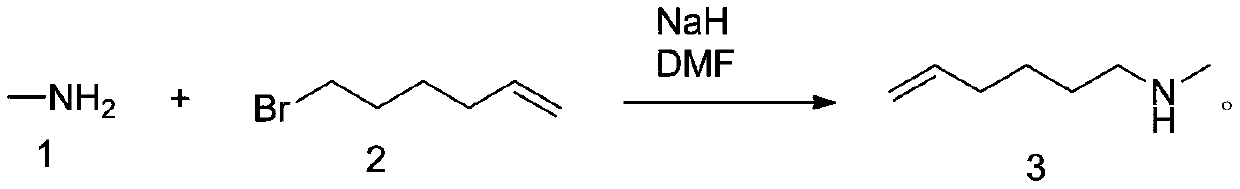

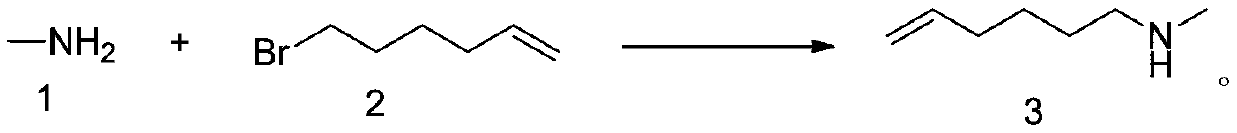

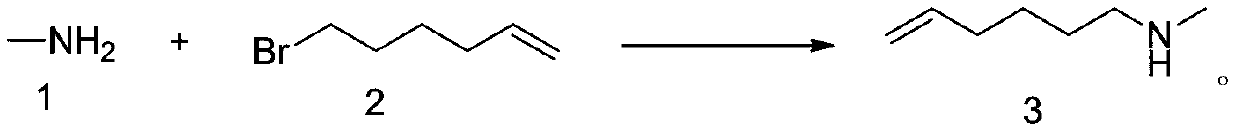

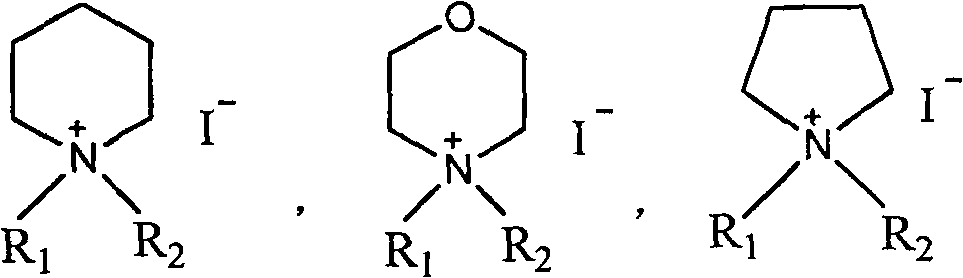

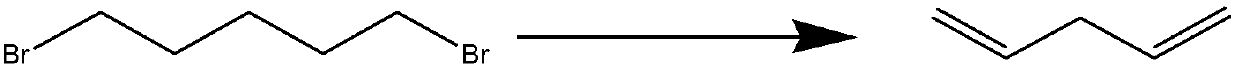

Synthesizing process of N-methyl-5-hexene-1-amine

ActiveCN108003037AEliminate potential safety hazardsPromote complete reactionAmino preparation by functional substitutionHydrogenOrganic solvent

The invention discloses a synthesizing process of N-methyl-5-hexene-1-amine, and relates to the technical field of medicine synthesis and removes the potential safety hazard that explosive hydrogen isgenerated in the existing process. The synthesizing process comprises the following steps: adding methylamine solution containing methylamine and a solvent into a reaction flask and then adding 6-bromine-1-hexene into the reaction flask, wherein the molar equivalent of methylamine is greater than that of 6-bromine-1-hexene; stirring the mixture; performing oil-bath heating to 40-50 DEG C, performing a reaction for 2-3h, cooling to 20 DEG C, adding a stabilizing agent, then adding sodium hydroxide, recycling excessive methylamine solution under negative pressure, heating to 50-60 DEG C, and performing reduced pressure distillation, so as to obtain colorless liquid, namely, the N-methyl-5-hexene-1-amine. According to the process, the explosive hydrogen is not generated, the synthesizing process is safe, no organic solvent extraction process exists, the process is environmentally friendly, and the product purity is high.

Owner:上海仁实医药科技有限公司

A kind of synthesis technique of n-methyl-5-hexen-1-amine

ActiveCN108003037BEliminate potential safety hazardsPromote complete reactionAmino preparation by functional substitutionOrganic solventDistillation

The invention discloses a synthesizing process of N-methyl-5-hexene-1-amine, and relates to the technical field of medicine synthesis and removes the potential safety hazard that explosive hydrogen isgenerated in the existing process. The synthesizing process comprises the following steps: adding methylamine solution containing methylamine and a solvent into a reaction flask and then adding 6-bromine-1-hexene into the reaction flask, wherein the molar equivalent of methylamine is greater than that of 6-bromine-1-hexene; stirring the mixture; performing oil-bath heating to 40-50 DEG C, performing a reaction for 2-3h, cooling to 20 DEG C, adding a stabilizing agent, then adding sodium hydroxide, recycling excessive methylamine solution under negative pressure, heating to 50-60 DEG C, and performing reduced pressure distillation, so as to obtain colorless liquid, namely, the N-methyl-5-hexene-1-amine. According to the process, the explosive hydrogen is not generated, the synthesizing process is safe, no organic solvent extraction process exists, the process is environmentally friendly, and the product purity is high.

Owner:上海仁实医药科技有限公司

Method for preparing faropenem daloxate

ActiveCN101235044BEasy to operateLow costOrganic chemistryAntiinfectivesCyclopenteneChemical synthesis

The invention relates to a preparation method of faropenem medoxomil, belonging to chemical synthesis technical field, which is characterized in that faropenem and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in an alkali condition and a solvent A, via a phase transfer catalyst and a reaction promoter containing iodine are synthesized to obtain faropenem medoxomil, orthe inorganic salt of faropenem medoxomil and 4-halogenated methyl radical-5-methyl-1, 3-dioxane cyclopentene-2-ketone, in a solvent B, via a phase transfer catalyst and reaction promoter containing iodine are synthesized to obtain faropenem medoxomil. The method has simple operation, mild reaction and saved cost, while the synthesized faropenem medoxomil has high yield and purity.

Owner:NANJING HUAWE MEDICINE TECH DEV +1

A kind of synthetic method of 5-chloro-1-pentene

ActiveCN105837396BInhibit side effectsAchieve low temperature reactionHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsAlcoholSynthesis methods

The invention discloses a 5-chloro-1-amylene synthesis method .The method comprises the steps that excess 4-amylene-1-alcohol and thionyl chloride are used as reaction raw materials, pyridine is used as a solvent, chlorination is catalyzed through a catalyst at low temperature, and5-chloro-1-amylene is obtained with high yield .The purpose of avoiding side reactions is achieved by changing technological conditions, and finally high selectivity and the high conversation rate of the reaction is achieved; after reaction liquid is processed, the product with the content of 98% or above can be obtained through a simple distillation means .By adding bismuth trioxide as the catalyst for catalyzing the reaction, low-temperature reaction is achieved, and the reaction conversion rate can reach 95.22% to the highest degree .

Owner:西安方昊化工有限公司

A kind of preparation method of cross-linked polycarboxylate water reducer using carboxyl functional monomer

The invention provides a preparation method for a cross-linking type polycarboxylate water reducer by adopting carboxyl functional monomers. The preparation method includes adding polyether macromonomers, hydroxyl functional monomers, phosphate functional monomers and water into a reaction kettle, and performing stirring and heating until a mixture is dissolved; controlling a temperature at 55-60DEG C, and starting adding an initial initiator, an osmotic agent and a chain transferring agent; simultaneously dropping a solution A and a solution B after 5 min, and starting dropping a solution Cwithin 10 min after the solution A and the solution B start dropping, the dropping time of the solution C being a hour, the dropping time of the solution A and the solution B being a+0.5 hours, the solution C consisting of carboxyl functional monomers and water, the solution A consisting of ascorbic acid, a cross-linking agent and water, and the solution B consisting of hydrogen peroxide and water; heating to 70-75 DEG C after the dropping is finished, keeping the temperature constant, performing curing for b hour, adding a neutralizer when the temperature of a to-be-reacted solution is less than 30 DEG C, and replenishing water to 1,000 parts so that a water reducer can be obtained. The polycarboxylate water reducer with high dispersibility and keeping slump can be obtained through the preparation method.

Owner:HUBEI UNIV OF TECH

Method for preparing N7-guanine alkylate

InactiveCN102276610BImprove solubilityPromote complete reactionOrganic chemistryDistillationEthyl acetate

The invention relates to a method for preparing an N7-guanine alkylate. The method comprises the following steps of: reacting 2'-deoxyguanosine serving as a raw material and iodoethane, ethylene oxide, 1-bromo-2-ethyl chloride, 3-allyl bromide or 1,2-dibromoethane serving as an alkylate in a dimethyl sulfoxide, glacial acetic acid or dimethyl acetamide solution at a temperature of 15-50 DEG C for0.5-96 hours; performing reduced pressure distillation after the reaction is finished; separating and purifying a rough product through silica gel column chromatography; and eluting with an eluent comprising acetic ether and petroleum ether in a volume ratio of (10-20):1 and an eluent comprising acetic ether and absolute methanol in the volume ratio of (10-20) :1 respectively to obtain the N7-guanine alkylate. The method has the advantages of mild reaction conditions, simple separation and purification process, high product yield, less environmental pollution and the like and contributes to mass production of the N7-guanine alkylate.

Owner:BEIJING UNIV OF TECH

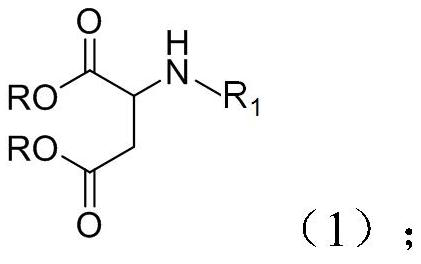

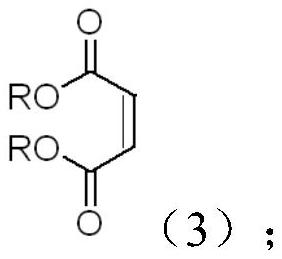

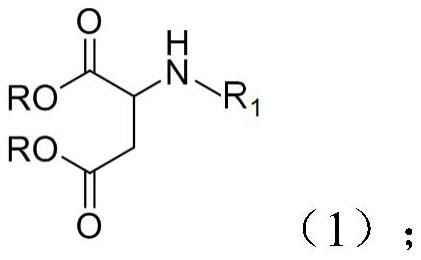

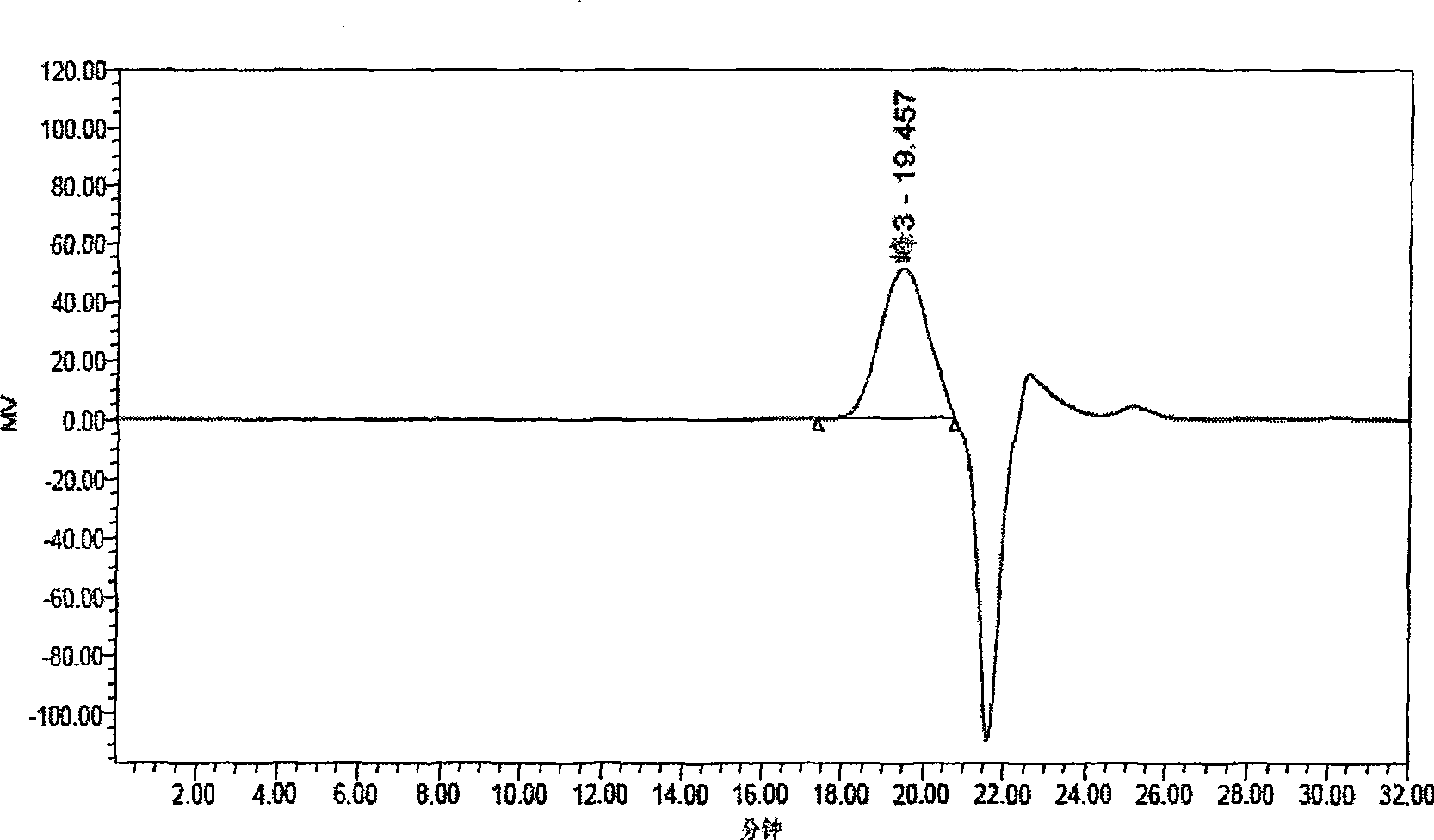

Polyurethane-aspartic polyurea resin, preparation method thereof and polymer

PendingCN114835597AControl the cure rateAvoid lostOrganic compound preparationAmino-carboxyl compound preparationPolymer scienceCross linker

The invention relates to the field of polymer synthesis, in particular to polyurethane-asparagine polyurea resin, a preparation method thereof and a polymer. The polyurethane-aspartic polyurea resin is prepared from the following raw materials: amino alcohol and diester maleate. According to the polyurethane-aspartic polyurea resin provided by the invention, one end of a secondary amine group is controlled to be connected with a diester group, the other end of the secondary amine group is controlled to be connected with a hydroxyl substituted naphthenic base, a novel resin structure containing the secondary amine group and hydroxyl is obtained, and different functional groups can be cured with different cross-linking agents such as polyisocyanates, polyepoxy compounds and the like by utilizing different activities of the different functional groups, so that the polyurethane-aspartic polyurea resin is prepared. And controlling the curing rate. According to the method disclosed by the invention, by controlling the appropriate dosage of the diester maleate and the primary amine, the complete reaction is promoted, the yield is improved, and meanwhile, the loss of a product in a drying process caused by excessive diester maleate is also avoided.

Owner:深圳飞扬兴业科技有限公司

Preparation method of high-performance dehydragent for graft copolymerization for carboxylate

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

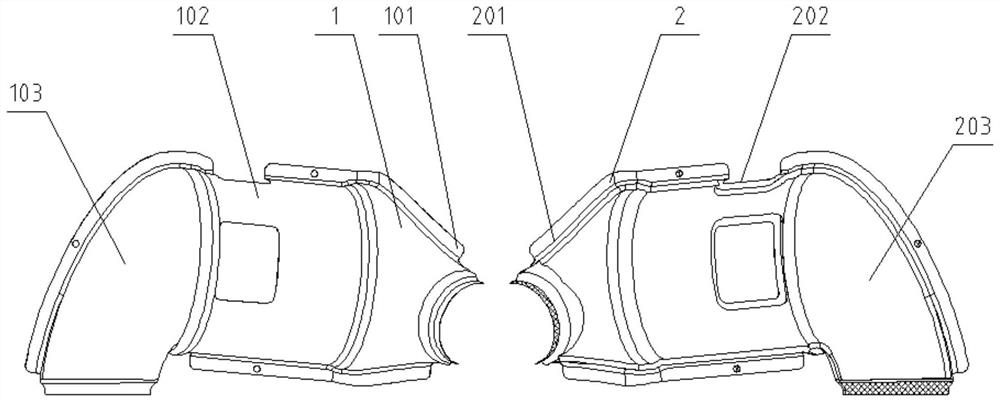

A kind of heat shield and its processing method

ActiveCN112443384BPromote complete reactionInsulation up toNon-macromolecular adhesive additivesExhaust apparatusGlass fiberThermodynamics

The invention discloses a heat shield and relates to the technical field of heat shields. The heat insulation cover includes a cover body and heat insulation cotton, the cover body is connected with the heat insulation cotton, the cover body includes an air intake section, a middle section and an exhaust section, and the air intake section is connected with the heat insulation cotton , the thickness of the cover body is 0.1-0.2mm, and the thickness of the heat insulation cotton is 5-7mm. The present invention uses SUS430 stainless steel with a thickness of 0.1-0.2mm as the cover body and glass fiber cotton with a thickness of 5-7mm as the heat insulation cotton, which can not only achieve heat insulation, promote the complete gas reaction, but also meet the requirements of light weight, and meet the national requirements. Six standards. The invention utilizes inorganic adhesives to ensure the assembly between the cover body and the heat insulation cotton, and can be firmly combined in a high temperature environment. The preparation method of the heat shield of the invention is simple and convenient for industrial application.

Owner:广州特拓新材料科技有限公司

Preparation method of modified magnesium oxide composite polishing powder

ActiveCN112646497BHave leftFunctionalPolishing compositions with abrasivesPolyethylene glycolOxide composite

This application relates to the technical field of polishing powder, and specifically discloses a preparation method of modified magnesium oxide composite polishing powder. The preparation method is as follows: step 1, mixing magnesium chloride, lanthanum chloride, cerium chloride, and praseodymium chloride into a solution, and then Mix with a fluorine-containing strong alkali solution to obtain a precursor solution; step 2, add pyridine, polyethylene glycol and p-toluenesulfonyl chloride to the above precursor solution, and then keep it warm at a temperature of 50°C-80°C After 2d-3d, the precursor precipitate is obtained after filtration; step 3, the precursor precipitate is placed in a high-temperature furnace, burned at a temperature of 900-1100°C, and then dispersed and classified to obtain modified oxidation Magnesium composite polishing powder. In this application, potassium p-benzenesulfonate and polyethylene glycol are used to generate ester groups with leaving and dispersing functions to improve the uniform dispersion of components in the precursor solution, thereby improving the cutting strength, yield and service life of the polishing powder as a whole .

Owner:深圳市瑞来稀土材料有限公司

Method and system for preparing biodiesel by tubular-variable temperature continuous method

ActiveCN108929787BOvercome the defect of short running cycleDischarge in timeFatty acid esterificationBiofuelsOil and greaseTemperature control

Owner:CHINA PETROLEUM & CHEM CORP +1

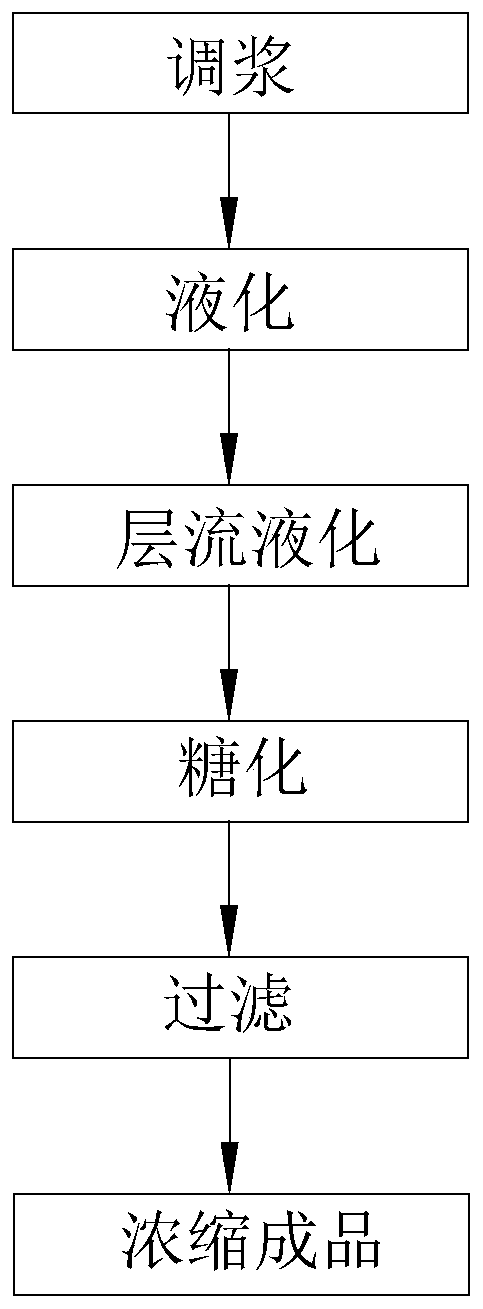

Production process of starch syrup applicable to milky tea

InactiveCN110846358ALarge degree of liquefactionIncrease glucose levelsPurification by physical meansFermentationEngineeringSweetness

The invention relates to the technical field of starch syrup, in particular to a production process of starch syrup applicable to milky tea. The production process includes steps of slurry mixing, liquefying, laminar flow liquefying, saccharifying, filtering and concentrating to obtain a finished product, and finally low-sweetness starch syrup with a DE value of 20-27 is prepared. In addition, thestarch syrup prepared according to the process is high in dextrin content, high in viscosity, soluble in water when being added into the milky tea and high in dispersity in the milky tea, and the milky tea has no unfavorable starch taste and tastes great. The starch syrup with the DE value ranging from 20-27 can be prepared without the step of saccharifying, so that a starch syrup preparation process is simplified. Moreover, liquefying enzymes only need to be added once in a liquefying stage.

Owner:双桥(厦门)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com