A kind of synthesis technique of n-methyl-5-hexen-1-amine

A synthesis process, hexene technology, applied in the preparation of amino-substituting functional groups, organic chemistry, etc., can solve the problems of safety hazards, low hydrogen explosion limit, etc., and achieve the effects of eliminating safety hazards, simple post-processing, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

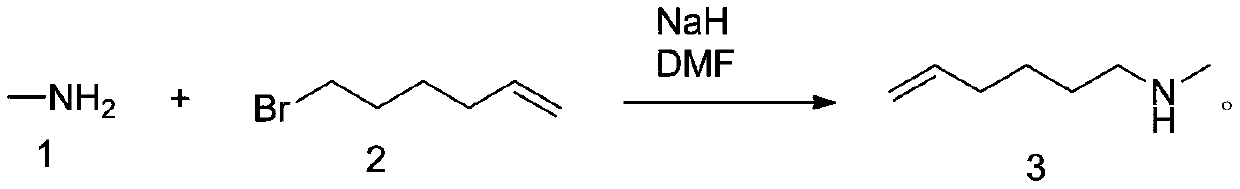

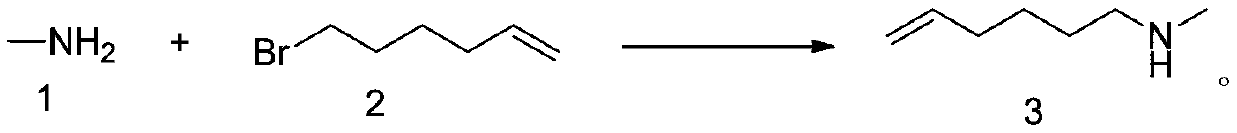

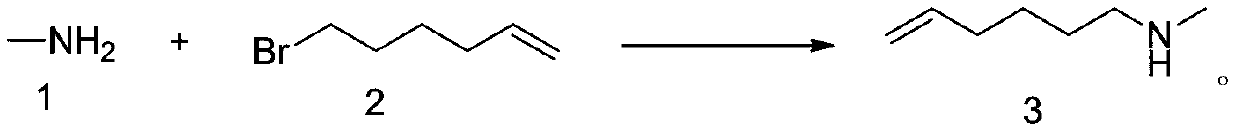

[0026] Embodiment 1: a kind of synthetic technique of N-methyl-5-hexen-1-amine, comprises the following steps: adding mass fraction in reaction bottle is the methylamine methanol solution of 25%, the content of methylamine is 2 equivalents , then add 1 equivalent of 6-bromo-1-hexene to the reaction flask, stir, heat the oil bath to 40°C, react for 3 hours, cool down to 20°C, add 0.1 equivalent of stabilizer, the stabilizer is p-formaldehyde Oxyphenol, add 1 equivalent of sodium hydroxide, recover excess methylamine methanol solution under negative pressure, heat to 50°C, and distill under reduced pressure to obtain a colorless liquid, which is N-methyl-5-hexene- 1-amine, the yield is 63%, and the purity is 95%; the synthesis process is carried out according to the following reaction formula:

[0027]

Embodiment 2

[0028] Embodiment 2: a kind of synthetic technique of N-methyl-5-hexene-1-amine, differs from embodiment 1, comprises the following steps: adding mass fraction in reaction bottle is the methylamine of 25% Methanol solution, the content of methylamine is 2 equivalents, then add 1 equivalent of 6-bromo-1-hexene to the reaction flask, stir, heat the oil bath to 45 °C, react for 2.5 hours, cool to 20 °C, add 0.1 Equivalent stabilizer, the stabilizer is p-methoxyphenol, add 1 equivalent of sodium hydroxide, recover excess methylamine methanol solution under negative pressure, heat to 55 ° C, and distill under reduced pressure to obtain a colorless liquid, which is N-methyl-5-hexen-1-amine, yield 64%, purity 95.2%.

Embodiment 3

[0029] Embodiment 3: a kind of synthetic technique of N-methyl-5-hexene-1-amine, differs from embodiment 1 in that, comprises the following steps: adding mass fraction in reaction bottle is the methylamine of 25% Methanol solution, the content of methylamine is 2 equivalents, then add 1 equivalent of 6-bromo-1-hexene to the reaction flask, stir, heat the oil bath to 50 ° C, react for 2 hours, cool down to 20 ° C, add 0.1 Equivalent stabilizer, the stabilizer is p-methoxyphenol, add 1 equivalent of sodium hydroxide, recover excess methylamine methanol solution under negative pressure, heat to 60°C, and distill under reduced pressure to obtain a colorless liquid, which is N-methyl-5-hexen-1-amine, yield 62%, purity 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com