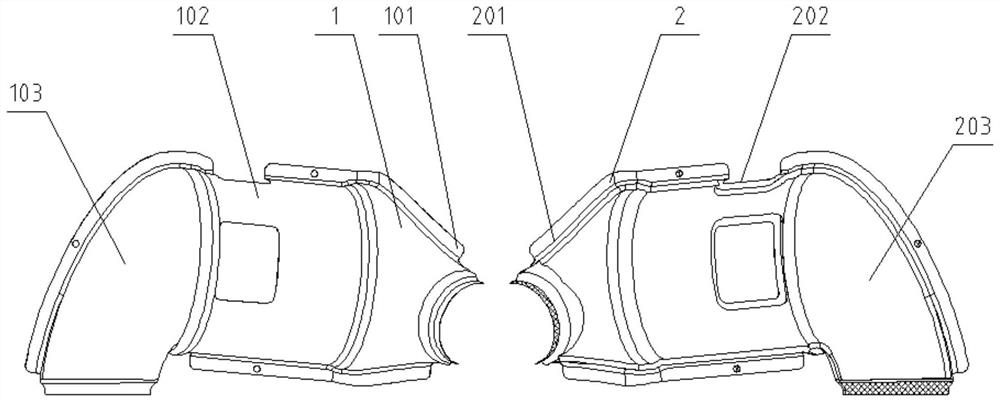

A kind of heat shield and its processing method

A heat shield and heat insulation cotton technology, applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of not meeting national emission standards, rapid loss, and damage to surrounding lines. and other problems, to achieve the effect of easy industrial application, simple preparation method, and improved assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

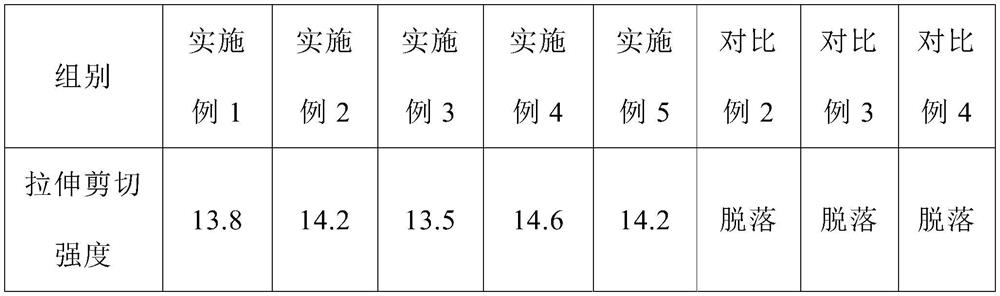

Embodiment 1

[0026] Example 1: A heat insulation cover, the cover body is made of SUS430 stainless steel, the thickness of the cover body is 0.1mm, the heat insulation cotton is glass fiber cotton, the thickness of the heat insulation cotton is 5mm, and the cover body and the heat insulation cotton are made of inorganic adhesive Inorganic adhesives include 60 parts of water glass, 3 parts of starch, 6 parts of glycerin, 120 parts of deionized water, 30 parts of copper oxide, 50 parts of silicon dioxide, 15 parts of ceramic fiber, and 6 parts of polyoxyethylene ether.

[0027] The preparation method of described inorganic adhesive is:

[0028] Step 1): Take 1 / 10 of the formula amount of deionized water, the formula amount, and the starch of polyoxyethylene ether, mix and stir until the starch is completely dissolved, then drop glycerin and mix and stir to obtain a mixed solution A;

[0029] Step 2): Take the water glass of the recipe amount and the deionized water of the remaining recipe am...

Embodiment 2

[0032] Embodiment 2: Similar to Embodiment 1, the difference is that the thickness of the cover body is 0.15 mm, and the thickness of the heat insulation cotton is 6 mm.

Embodiment 3

[0033] Embodiment 3: Similar to Embodiment 1, the difference is that the thickness of the cover body is 0.2 mm, and the thickness of the heat insulation cotton is 7 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com