Method and system for preparing biodiesel by tubular-variable temperature continuous method

A biodiesel, continuous process technology, applied in the fields of biofuel, petroleum industry, fatty acid esterification, etc., can solve the problem that the sediment device cannot run stably for a long period of time, and achieve the effect of high reaction conversion rate and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

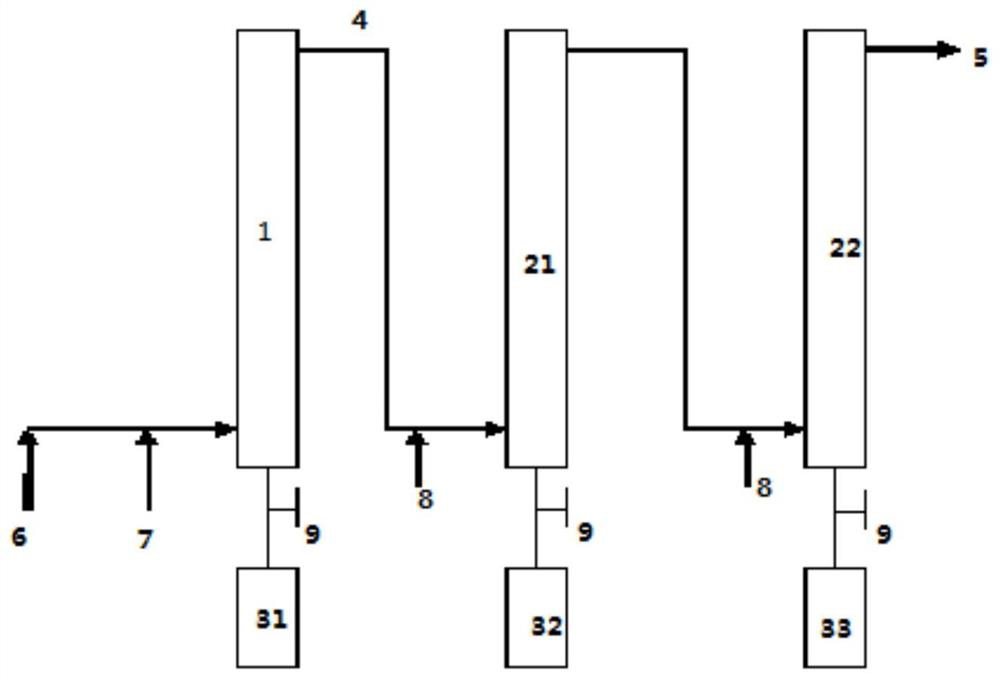

[0086] The waste oil and methanol are continuously supplied to the first vertical tubular reactor at a rate of 600 g / h and 155 g / h respectively, and the liquid hourly volume space velocity is 1 h -1 , the temperature of the first vertical tubular reactor is 120°C, the pressure is 6Mpa, the liquid phase material flows from bottom to top in the first vertical tubular reactor, while the first vertical tubular reactor The sediment in the tank enters into the sediment collection tank at the bottom of the first vertical tubular reactor by gravity. The first material that escapes from the upper part of the first vertical tubular reactor enters the lower part of the second vertical tubular reactor I, the temperature of the second vertical tubular reactor I is 190 ° C, and the added methanol Amount is 32 grams / hour, and the material after the reaction draws from the top of the second vertical tubular reactor I, and enters the bottom of the second vertical tubular reactor II, the temper...

Embodiment 2

[0096] Waste oil and methanol are continuously supplied to the first vertical tubular reactor at a rate of 600 g / h and 181 g / h respectively, and the liquid hourly volume space velocity is 1.2h -1 , the temperature of the first vertical tube reactor is 140°C, the pressure is 5.7Mpa, the main liquid phase material flows from bottom to top in the first vertical tube reactor, while the first vertical tube The sediment in the first vertical tubular reactor enters into the sediment collection tank at the bottom of the first vertical tubular reactor by gravity. The first material that escapes from the upper part of the first vertical tubular reactor enters the lower part of the second vertical tubular reactor I, the temperature of the second vertical tubular reactor I is 190 ° C, and the added methanol Amount is 46 grams / hour, and the material after the reaction draws from the top of the second vertical tubular reactor I, and enters the bottom of the second vertical tubular reactor I...

Embodiment 3

[0099] Acidified oil and methanol are continuously supplied to the first vertical tubular reactor at a rate of 600 g / h and 167 g / h respectively, and the liquid hourly volume space velocity is 0.7h -1 , the temperature of the first vertical tube reactor is 140°C, the pressure is 4.9Mpa, the main liquid phase material flows from bottom to top in the first vertical tube reactor, while the first vertical tube The sediment in the first vertical tubular reactor enters into the sediment collection tank at the bottom of the first vertical tubular reactor by gravity. The first material that escapes from the upper part of the first vertical tubular reactor enters the lower part of the second vertical tubular reactor I, the temperature of the second vertical tubular reactor I is 210 ° C, and the added methanol Amount is 40 grams / hour, and the material after the reaction draws from the top of the second vertical tubular reactor I, and enters the bottom of the second vertical tubular react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com