Production process of starch syrup applicable to milky tea

A technology of starch syrup and production process, applied in sugar production, sucrose production, application, etc., can solve the problems of high syrup sweetness, low syrup dextrin content, difficult addition amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

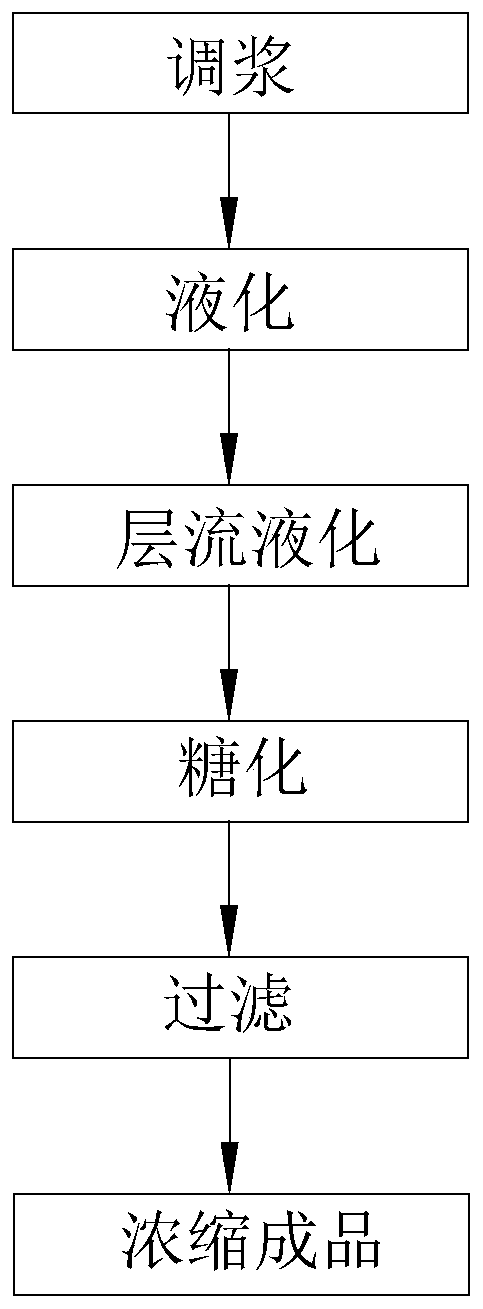

[0038] A production process of starch syrup suitable for milk tea, specifically comprising the following steps:

[0039] Step 1, pulping: starch and water are added into the pulping tank according to the mass ratio of 1:1 and stirred evenly, the pH of the starch slurry is adjusted to 5.4, and then the liquefaction enzyme is added and stirred evenly, the amount of the liquefaction enzyme added is 1% of the starch mass 0.02%, the liquefying enzyme is α-high temperature amylase;

[0040] Step 2. Liquefaction: The starch slurry in step 1 is transported to the liquefaction tank, and the starch milk is liquefied by steam and injected into the flash tank for flash evaporation. The injection temperature is controlled at 103°C, the injection time is controlled at 6 minutes, and the temperature of the flash tank is controlled. At 90°C, the flash time is 5 minutes;

[0041]Step 3, laminar flow liquefaction: transport the starch milk liquefied in step 2 to the laminar flow column for lam...

Embodiment 2

[0046] A production process of starch syrup suitable for milk tea, specifically comprising the following steps:

[0047] Step 1, pulping: Starch and water are added into the pulping tank according to the mass ratio of 1:1.2 and stirred evenly, the pH of the starch slurry is adjusted to 6.1, and then the liquefying enzyme is added and stirred evenly. 0.04%, the liquefying enzyme is α-high temperature amylase;

[0048] Step 2. Liquefaction: The starch slurry in step 1 is transported to the liquefaction tank, and the starch milk is liquefied by steam and injected into the flash tank for flash evaporation. The injection temperature is controlled at 110°C, the injection time is controlled at 15 minutes, and the temperature of the flash tank is controlled. At 95°C, the flash time is 6 minutes;

[0049] Step 3, laminar flow liquefaction: transport the starch milk liquefied in step 2 to the laminar flow column for laminar flow liquefaction, the temperature of laminar flow liquefactio...

Embodiment 3

[0054] A production process of starch syrup suitable for milk tea, specifically comprising the following steps:

[0055] Step 1, pulping: starch and water are added into the pulping tank according to the mass ratio of 1:1.5 and stirred evenly, the pH of the starch slurry is adjusted to 5.8, and then the liquefying enzyme is added and stirred evenly. 0.03%, the liquefying enzyme is α-high temperature amylase;

[0056] Step 2. Liquefaction: The starch slurry in step 1 is transported to the liquefaction tank, and the starch milk is liquefied by steam and injected into the flash tank for flash evaporation. The injection temperature is controlled at 115°C, the injection time is controlled at 10 minutes, and the temperature of the flash tank is controlled. At 100°C, the flash time is 8 minutes;

[0057] Step 3, laminar flow liquefaction: transport the starch milk liquefied in step 2 to the laminar flow column for laminar flow liquefaction, the temperature of laminar flow liquefacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com