CaFe2O4 type magnetic solid catalyst and application thereof

A solid catalyst and magnetic technology, applied in the direction of physical/chemical process catalysts, applications, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult recycling of solid catalysts, complex components of magnetic solid catalysts, solid catalysts and Difficult separation of cellulose residues and other problems, to achieve the effect of reducing hydrolysis cost, simple preparation method, and improving hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

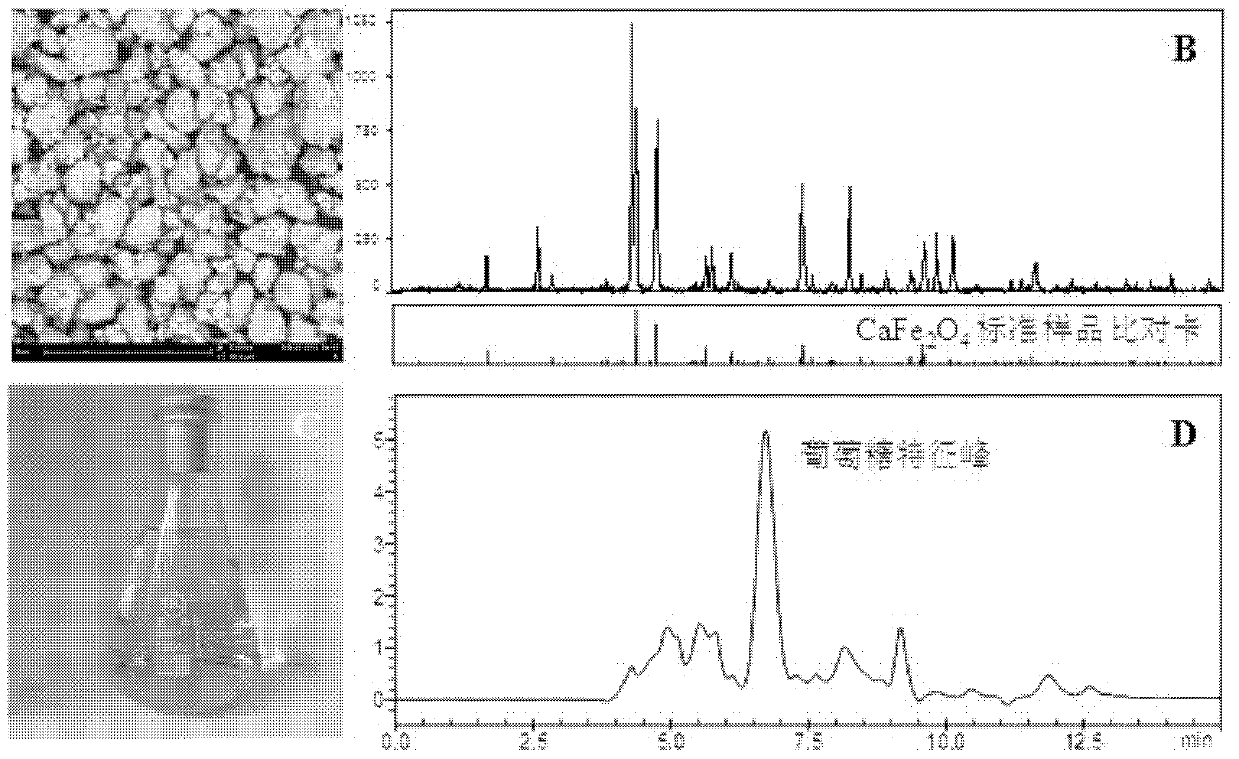

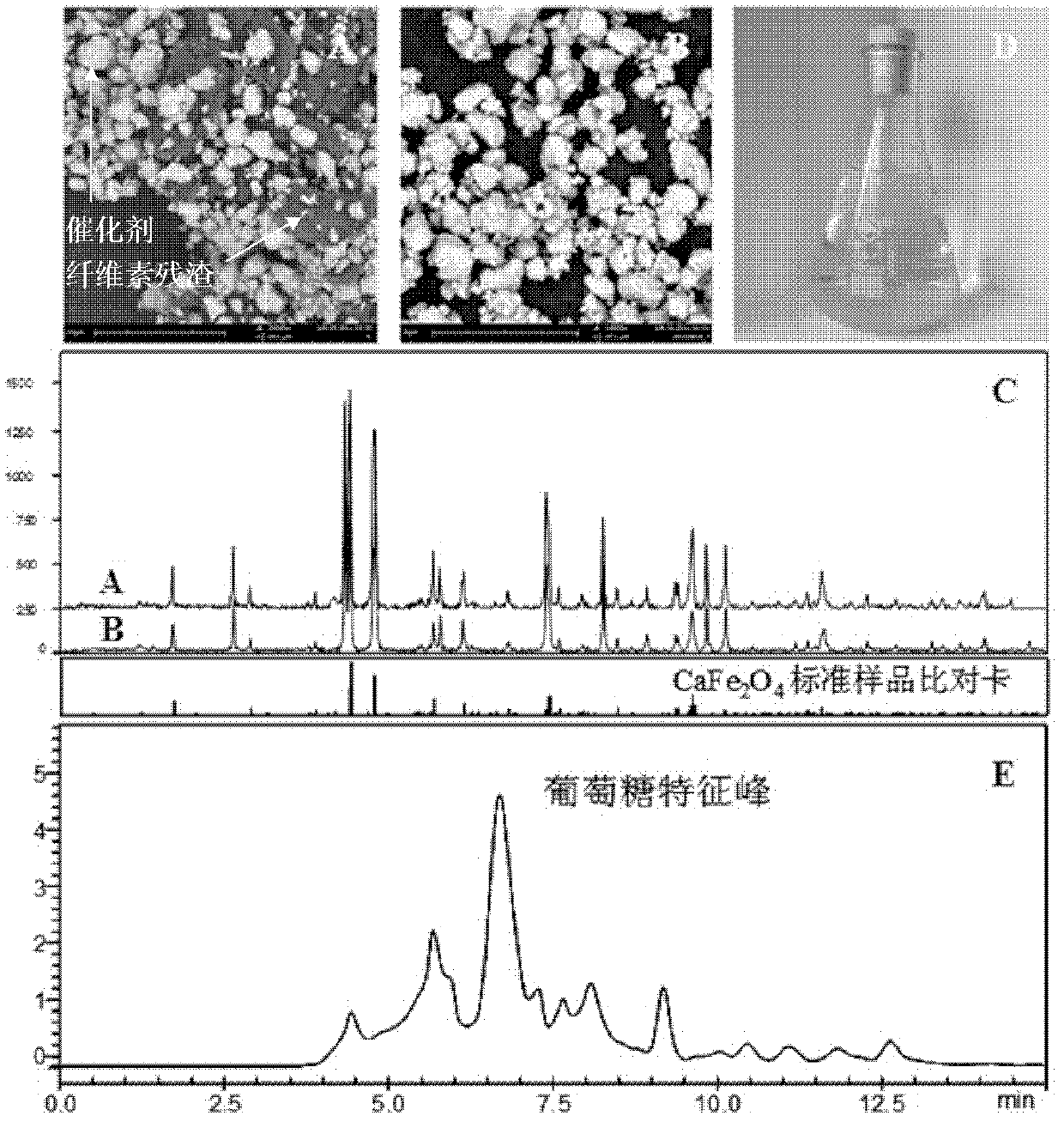

[0035] Press n[Ca(NO 3 ) 2 ]: n[Fe(NO 3 ) 3 ]=2:1, n[urea]:n[metal ion]=5:1, n[H 2 O]:n[urea]=20:1 to form a mixed solution, and the mixed solution was uniformly stirred and reacted at 135°C for 12h, and then the reaction solution was left to stand at 95°C for 12h, then the precipitate was washed to neutral, and then centrifuged Obtain the precipitate, dry the precipitate and grind it into 1~100μm powder, then calcined at 1000°C for 3h, the obtained product is CaFe 2 o 4 type magnetic solid catalyst.

[0036] Prepare a homogeneous mixture according to the mass ratio of magnetic solid catalyst to cellulose of 1.5:1, prepare 150mL of homogenate according to the mass ratio of pure water to mixture of 15:1, heat the homogenate to 150°C within 50min, and catalyze it at a stirring rate of 300rpm After 24 hours of reaction, the cellulose hydrolysis mixture was obtained, and separated under 20000g centrifugal force for 10 minutes to obtain the cellulose hydrolysis solution and t...

Embodiment 2

[0042] Electromagnetic equipment is used to separate the magnetic solid catalyst in Example 1, and the recovery rate of the catalyst is 99%, and it is used for the second time after being dried at 300° C. for 1 h. The mass ratio of magnetic solid catalyst to cellulose is 1.5:1 Prepare a homogeneous mixture, make 150mL homogenate according to the mass ratio of pure water and mixture at 15:1, heat the homogenate to 150°C within 50min, and catalyze the reaction at a stirring rate of 300rpm for 24h to obtain a cellulose hydrolysis mixture, at 20000g Separation under centrifugal force for 10 minutes to obtain cellulose hydrolyzate and solid mixture, after drying the solid mixture, using electromagnet equipment to separate the magnetic solid catalyst in the solid mixture for reuse.

[0043] Measure the carbon-containing quality of the cellulose hydrolyzate with a total organic carbon analyzer, calculate the cellulose hydrolysis rate by formula 1 is 42%, measure the glucose content in...

Embodiment 3

[0046] Electromagnetic equipment is used to separate the magnetic solid catalyst in Example 2, and the catalyst recovery rate is 96%. It is used for the third time after being dried at 300° C. for 1 h. The mass ratio of magnetic solid catalyst to cellulose is 1.5:1 Prepare a homogeneous mixture, make 150mL homogenate according to the mass ratio of pure water and mixture at 15:1, heat the homogenate to 150°C within 50min, and catalyze the reaction at a stirring rate of 300rpm for 24h to obtain a cellulose hydrolysis mixture, at 20000g Separation under centrifugal force for 10 minutes to obtain cellulose hydrolyzate and solid mixture, after drying the solid mixture, using electromagnet equipment to separate the magnetic solid catalyst in the solid mixture for reuse.

[0047] Measure the carbon-containing quality of the cellulose hydrolyzate with a total organic carbon analyzer, calculate the cellulose hydrolysis rate by formula 1 is 40%, measure the glucose content in the cellulo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com