Preparation method of solid flake polycarboxylate slump retention agent for bulk polymerization

A bulk polymerization and polycarboxylic acid technology, which is applied in the field of building materials and concrete admixtures, can solve the problems of high viscosity in anhydrous environment and low collision reaction efficiency, and achieve excellent emulsification, good economy and operability, and reduce air bubbles The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

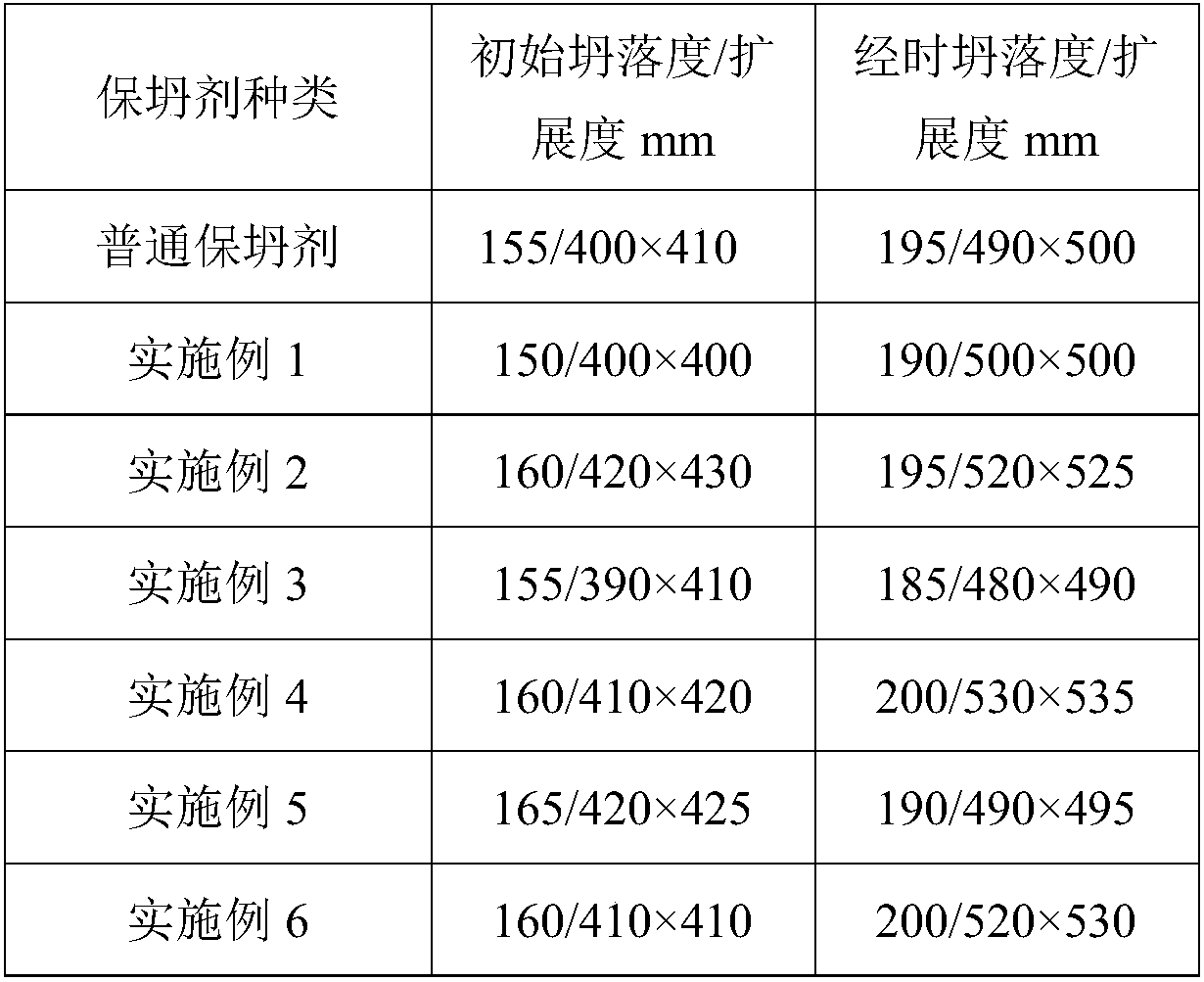

Examples

Embodiment 1

[0035] The preparation method of bulk polymerized solid sheet polycarboxylate slump retaining agent is prepared from the following components: polyether macromonomer, fluorinated functional monomer, Alkyl acrylate, acrylic acid, initial initiator, organic peroxygen initiator, solubilizer, chain transfer agent, viscosity reducer, lubricant, penetrating agent, neutralizing agent; the total mass is 1000 parts, and the preparation method comprises the following steps:

[0036] 1) Mix 840 parts of liquid prenol polyoxyethylene ether, 2 parts of a composition of polymethylfluorosiloxane and nonylphenol polyoxyethylene ether in a mass ratio of 1:2, and 1 part of a composition with a mass ratio of 1:2 The composition of erucamide and oleamide is added into the reaction kettle, stirred and heated;

[0037] 2) Measure the temperature in the kettle, control the temperature at 100°C, and after the temperature is stable, add 2.2 parts of sodium tripolyphosphate and sodium lauryl sulfate at...

Embodiment 2

[0041] A method for preparing bulk polymerized solid sheet polycarboxylate slump-retaining agent. The bulk polymerized solid sheet polycarboxylate water reducer is prepared from the following components: polyether macromonomer, fluorinated functional monomer, Alkyl acrylate, acrylic acid, initial initiator, organic peroxygen initiator, solubilizer, chain transfer agent, viscosity reducer, lubricant, penetrating agent, neutralizing agent; the total mass is 1000 parts, and the preparation method comprises the following steps:

[0042] 1) 880 parts of a composition of isopentenol polyoxyethylene ether and vinyl butyl ether polyoxyethylene ether with a liquid mass ratio of 1:1, 5 parts of polymethylfluorosiloxane with a mass ratio of 1:1 Add the composition of nonylphenol polyoxyethylene ether, 3 parts of calcium stearate and oleic acid amide with a mass ratio of 1:2 into the reactor, stir and heat;

[0043] 2) Measure the temperature in the kettle, control the temperature at 105°...

Embodiment 3

[0047] A method for preparing bulk polymerized solid sheet polycarboxylate slump-retaining agent. The bulk polymerized solid sheet polycarboxylate water reducer is prepared from the following components: polyether macromonomer, fluorinated functional monomer, Alkyl acrylate, acrylic acid, initial initiator, organic peroxygen initiator, solubilizer, chain transfer agent, viscosity reducer, lubricant, penetrating agent, neutralizing agent; the total mass is 1000 parts, and the preparation method comprises the following steps:

[0048] 1) Add 863 parts of liquid methallyl polyoxyethylene ether, 3 parts of nonylphenol polyoxyethylene ether, and 2 parts of stearic acid amide into the reaction kettle, stir and heat;

[0049] 2) Measure the temperature in the kettle and control the temperature at 101°C. After the temperature is stable, add 2.5 parts of sodium tripolyphosphate, 7 parts of 2-acrylamide-2-methylpropanesulfonic acid, and 0.8 parts of dicumyl peroxide at one time , 0.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com