A kind of preparation method of cross-linked polycarboxylate water reducer using carboxyl functional monomer

A technology of functional monomer and water-reducing agent, applied in the fields of building materials and concrete admixtures, can solve the problems of poor slump retention, concrete segregation and bleeding, and high cost of slump-retaining agents, achieve high synthesis temperature, improve reaction Active, good anti-adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

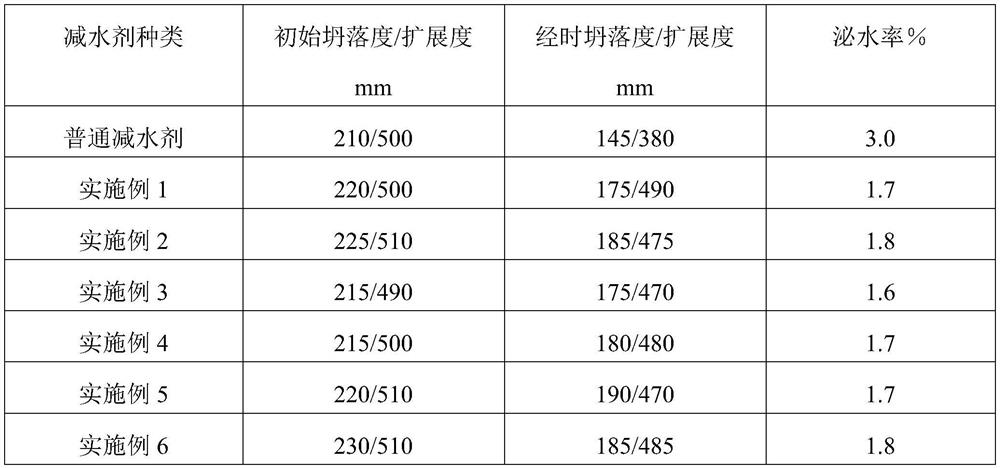

Examples

Embodiment 1

[0036] A method for preparing a cross-linked polycarboxylate water reducer using carboxyl functional monomers. The water reducer is mainly prepared from the following components: polyether macromonomers, hydroxyl functional monomers, and phosphate ester functional monomers , penetrating agent, chain transfer agent, initial initiator, ascorbic acid, crosslinking agent, hydrogen peroxide, carboxyl functional monomer, neutralizing agent and water; total mass 1000 parts, the finished product mass fraction after preparation is 40%, and the preparation method comprises the following steps :

[0037] 1) 335 parts of isopentenol polyoxyethylene ether, 6 parts of polyethylene glycol dimethacrylate, 7 parts of polyethylene glycol monomethacrylate and polyethylene glycol formaldehyde in a mass ratio of 1:2 Add the composition of ether methacrylate and 200 parts of water into the reaction kettle, stir and heat until it dissolves;

[0038] 2) Measure the temperature in the kettle, and con...

Embodiment 2

[0042] A method for preparing a cross-linked polycarboxylate water reducer using carboxyl functional monomers. The water reducer is mainly prepared from the following components: polyether macromonomers, hydroxyl functional monomers, and phosphate ester functional monomers , penetrating agent, chain transfer agent, initial initiator, ascorbic acid, crosslinking agent, hydrogen peroxide, carboxyl functional monomer, neutralizing agent and water; total mass 1000 parts, the finished product mass fraction after preparation is 40%, and the preparation method comprises the following steps :

[0043] 1) Add 340 parts of allyl polyoxyethylene ether, 4 parts of polyethylene glycol monomethacrylate, 6 parts of ethylene glycol methacrylate phosphate and 190 parts of water into the reactor, stir and heat until the dissolve;

[0044] 2) Measure the temperature in the kettle, control the temperature at 56° C., and after the temperature is stable, add 0.15 parts of the composition of sulfat...

Embodiment 3

[0048] A method for preparing a cross-linked polycarboxylate water reducer using carboxyl functional monomers. The water reducer is mainly prepared from the following components: polyether macromonomers, hydroxyl functional monomers, and phosphate ester functional monomers , penetrating agent, chain transfer agent, initial initiator, ascorbic acid, crosslinking agent, hydrogen peroxide, carboxyl functional monomer, neutralizing agent and water; total mass 1000 parts, the finished product mass fraction after preparation is 40%, and the preparation method comprises the following steps :

[0049] 1) The composition of 345 parts of methallyl polyoxyethylene ether, 5 parts of polyethylene glycol monomethacrylate and polyethylene glycol dimethacrylate with a mass ratio of 1:1, 5 parts of mass ratio A 1:1 composition of methacryloxyethyl phosphate and ethylene glycol methacrylate phosphate, and 180 parts of water are added to the reactor, stirred and heated until it dissolves;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com